For an increasingly connected world, remote work is becoming the norm, especially in industries like engineering, where design and product development require input from experts across various locations. The shift to remote work presents challenges, particularly when it comes to maintaining clear communication, managing heavy design data, and ensuring consistency throughout your engineering process.

With the increasing reliance on digital tools, companies need efficient solutions to keep everyone on the same page, regardless of where they’re working. SOLIDWORKS PDM provides a centralized hub where teams can securely store, access, and manage critical product data such as schematics, CAD models, and bills of materials (BOMs).

By bridging the gap between remote engineering teams and offering secure access to product and design information, SOLIDWORKS PDM not only enhances collaboration but frees up your team to spend less time on management and more time on innovation and driving product development forward.

What is Product Data Management (PDM)?

Product Data Management (PDM) is a digital system that helps engineering teams organize and control their product data throughout the development process. For SOLIDWORKS PDM, this is your Vault. It acts as a centralized repository where team members can store, share, and track revisions of design files, schematics, and other crucial documents. Remote engineers can easily access the information they need, resulting in less time spent searching for files and more time on actual product development.

For more information on What PDM is and why it’s important, check out our latest blog on the subject!

How Does PDM Support Remote Engineering Teams?

Successful remote engineering teams thrive on smooth and efficient collaboration. SOLIDWORKS PDM plays a critical role in making this possible for teams dispersed across different locations through user-friendly features and CAD-aware file sharing capabilities. For example:

- SOLIDWORKS PDM enables remote teams to collaborate seamlessly by centralizing all product data, including CAD models and documentation, in a secure vault. Through cloud or VPN access, engineers can retrieve and update files from anywhere, ensuring they always work with the latest versions.

- PDM’s version control tracks every change, preventing overwrites and ensuring clarity on who made edits and when. Automated revision management reduces errors and keeps projects on track.

- File sharing is simplified. Engineers can check files in and out, with controllable permissions ensuring secure access to sensitive data.

- Customizable workflows automate approvals and change requests, allowing global teams to maintain momentum without delays.

- Integration with SOLIDWORKS CAD and BOM management ensures consistency and efficiency across all product development stages.

Remote engineering teams can retrieve, modify, and update files in real time, ensuring that everyone works with the most current version of the data, reducing the risk of errors or duplication. By leveraging these features, SOLIDWORKS PDM helps your teams stay connected to their product data, collaborate effectively, and maintain high levels of productivity, no matter where they are in the world.

Can PDM Improve Communication for Remote Engineering Teams?

Absolutely. By integrating product data management with communication tools such as emails and messaging platforms, engineers and project managers can easily discuss design data and track changes in real-time. The use of software that combines CAD tools and data management solutions creates a collaborative environment, ensuring everyone is working from the latest versions of schematics and designs.

How Does PDM Integrate with CAD Tools?

SOLIDWORKS PDM is designed to work seamlessly within your familiar SOLIDWORKS CAD environment. By linking your CAD information directly to the product data management system, remote engineers can track revisions, update models, and share designs in real-time. This seamless connection ensures that all product development tasks are carried out using the most up-to-date data, reducing errors and improving overall efficiency.

Handling Change Orders

Tracking change orders is one of the most important aspects of any engineering process. SOLIDWORKS PDM provides transparency by ensuring all changes are documented and reviewed by the necessary stakeholders, regardless of location. This ensures that the latest version of any design is available for all team members, reducing confusion, and improving project workflows.

Enhancing Collaboration with Schematics and BOM Management

Handling complex projects involving detailed schematics and BOM can be a challenge for remote teams. PDM simplifies this by providing an organized platform where engineers can collaborate, track changes, and ensure that all information is accessible in one place. This leads to more efficient engineering processes and a smoother overall product development lifecycle.

Startups and Growing Companies

For startups and smaller companies, implementing a product data management system might seem like a significant investment. However, the ability to manage product data effectively from the outset can greatly improve scalability. As remote work becomes more common, PDM ensures that all team members can access necessary information, contributing to smoother project timelines and efficient workflows.

A Solution for Global Collaboration

For globally dispersed teams, effective data management is key. A well-implemented PDM system facilitates seamless collaboration between offices located in different parts of the world. By managing data centrally, remote engineers can work on shared projects without geographical limitations, leading to more efficient workflows and faster time-to-market.

Best Practices for Remote Work in Engineering

Remote engineers and project managers benefit from establishing best practices when working with PDM. Regularly reviewing change orders, organizing BOMs, and maintaining open lines of communication are essential for keeping projects on track. With PDM in place, these practices become easier to follow, ensuring consistency across the board.

Why Choose Cloud-Based Solutions for Remote Engineers?

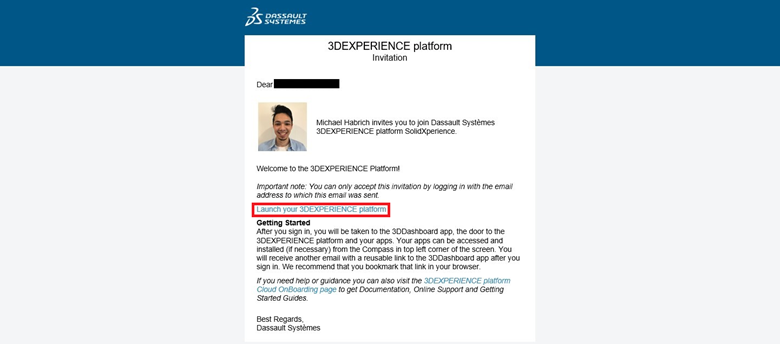

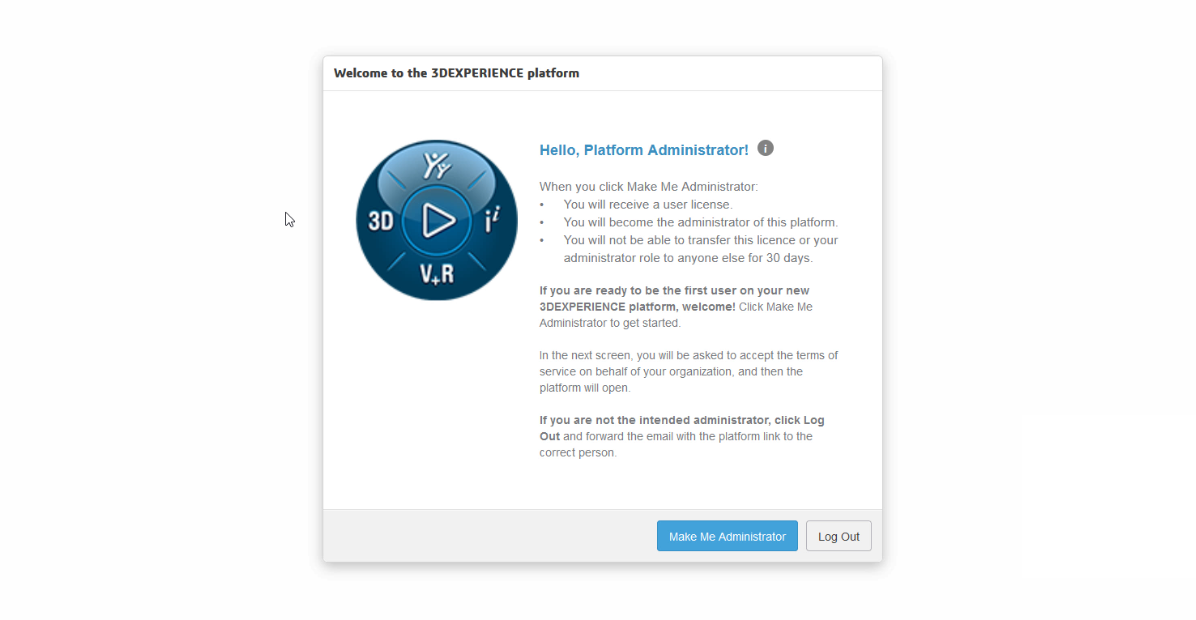

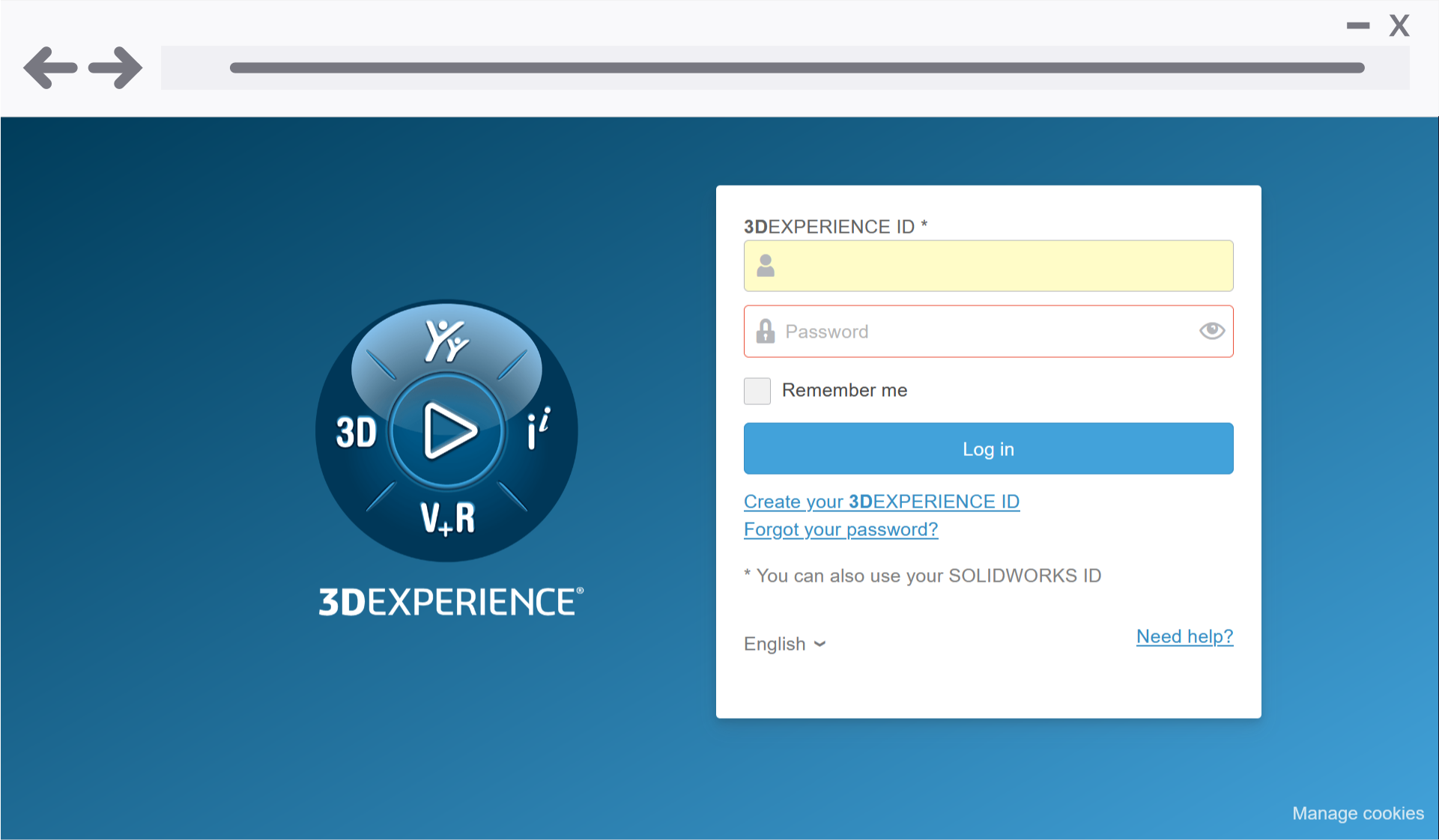

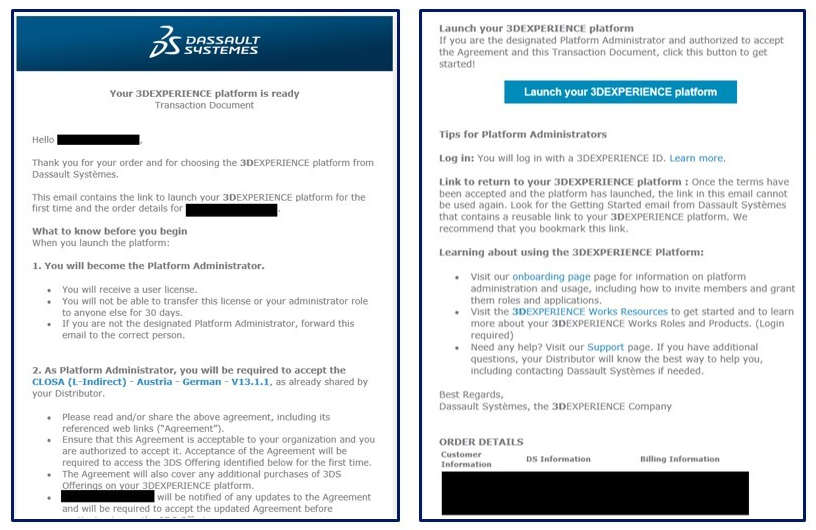

Cloud-based solutions, like the 3DEXPERIENCE platform, have transformed how remote engineering teams collaborate. By hosting product data management on the cloud, teams no longer need to worry about local servers or hardware issues. Instead, they can access their designs from anywhere, as long as there’s an internet connection. This flexibility allows teams to stay productive even when working from different locations.

What Role Does PLM Play in Remote Collaboration?

PDM manages product data, while PLM oversees the entire product lifecycle. Integrated together, these solutions assist remote teams in managing design, logistics, manufacturing, and end-of-life processes for a holistic view of the product journey.

Benefits of Combining Systems

Taking this integration one step further, incorporating enterprise resource planning (ERP) with your PDM ensures better coordination between design and manufacturing. By linking the BOM from CAD with ERP systems, companies can better manage production schedules, raw materials, and delivery timelines. This is particularly helpful for remote teams, as it keeps all departments aligned with project milestones and progress.

Streamlining Engineering Processes

The use of PDM allows engineering teams to follow best practices for managing product development and engineering processes. By providing a structured way to manage design data, teams avoid duplicate files, conflicting versions, and communication breakdowns. This is essential when working remotely, as remote engineers need to rely on efficient data management to avoid costly mistakes.

Final Thoughts on PDM for Remote Engineering Teams

With a product data management system in place, remote engineers can easily collaborate across different regions and time zones, ensuring that everyone is working with the latest files and data. This creates a more streamlined workflow, where design revisions, change orders, and BOMs are managed in a single platform that all team members can access with an internet connection. Additionally, integrating PDM with other tools like CAD and PLM solutions further enhances this collaboration, providing an end-to-end solution for managing not only product data but also the broader aspects of the product lifecycle.

For companies of all sizes—from established corporations to growing startups—implementing PDM can transform how projects are managed and executed, leading to more efficient engineering processes and faster time-to-market. Stay connected, collaborative, and productive, no matter where you and your team members are in the world.