Abstract

The 3D SheetMetal Creator role on the 3DEXPERIENCE platform, available in the SOLIDWORKS Cloud Offer, streamlines sheet metal design with powerful browser-based tools for creating precise 3D geometries and manufacture-ready 2D flat patterns. Key features like the Jog Command, Bend Order Table, Sheet Metal Hole Command, Closed Corner, and Point or Curve Mapping enhance efficiency by reducing manual steps, organizing manufacturing details, standardizing hole creation, simplifying flange gap closure, and enabling detailed flat pattern mapping for better communication with manufacturers. These tools save time, improve design accuracy, and ensure seamless collaboration from design to production.

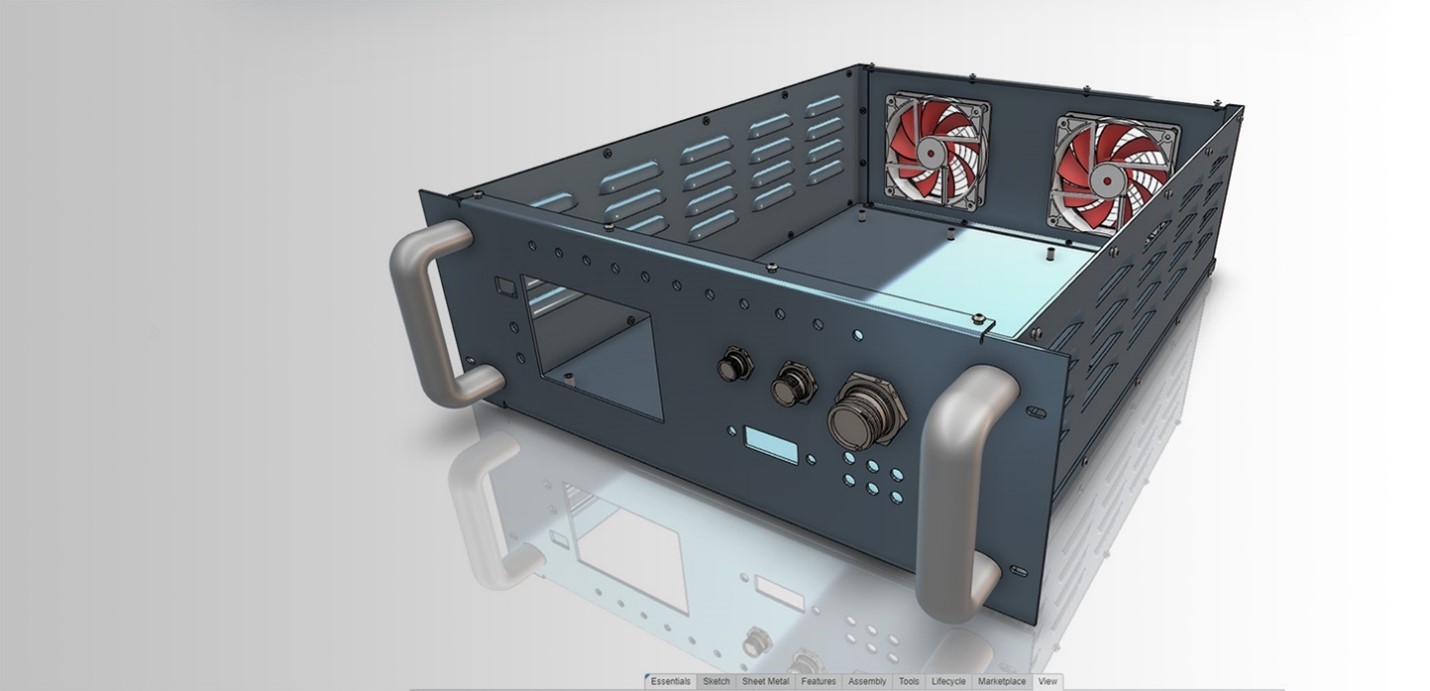

Introduction

3D SheetMetal Creator, part of the 3DEXPERIENCE platform, is a browser-based solution tailored to streamline sheet metal design. It empowers users to create intricate 3D geometries, automatically generate 2D flat patterns, and enhance collaboration through seamless integration with other tools in the platform. Whether you are a seasoned designer or new to sheet metal work, the recent updates to 3D SheetMetal Creator make it an essential tool for efficient and precise design. Here, we explore five new features that significantly improve the user experience, alongside a deeper dive into the software’s capabilities.

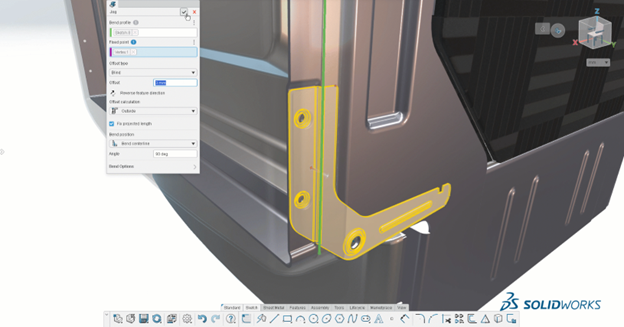

1. Jog Command

The new Jog Command simplifies the process of creating bends in sheet metal parts. With this feature, you can quickly add two bends using a single sketch, reducing the need for multiple steps. This capability is particularly useful when designing features like stiffening ribs or decorative jogs, where two bends often occur in tandem.

For example, instead of creating separate sketches for each bend and applying individual bend features, the Jog Command combines these actions into one seamless operation. This not only saves time but also ensures greater consistency in your design. By minimizing manual input, the Jog Command helps eliminate errors and enhances productivity for designers working under tight deadlines.

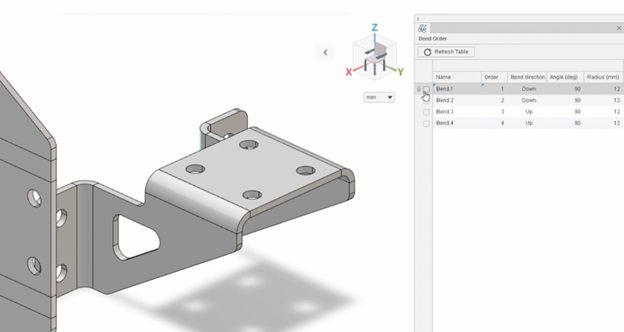

2. Bend Order Table

The Bend Order Table is a game-changer for improving communication between designers and manufacturers. This feature provides a tabular representation of a sheet metal component’s bends, detailing critical information such as bend order, direction, angle, and radius.

By simply dragging rows within the table, you can reorder bends to optimize manufacturing processes. This flexibility makes it easier to communicate manufacturing intent to shop floor teams. Additionally, you can rename bends to indicate stages (e.g., “Stage 1 Bend” or “Final Bend”), adding clarity to complex designs.

With the Bend Order Table, collaboration becomes more straightforward. Manufacturers can better understand and execute designs, reducing errors and costly rework. This feature bridges the gap between virtual designs and physical production, ensuring smooth handoffs at every stage of the workflow.

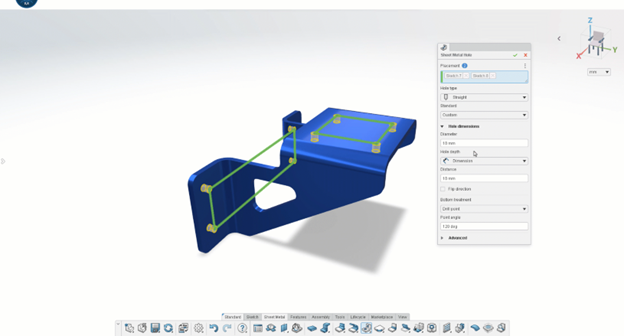

3. Sheet Metal Hole Command

The Sheet Metal Hole Command makes it easier than ever to create holes across multiple sketches and planes in one operation. This command supports:

- Predefined industry-standard hole types, including those tailored for sheet metal (e.g., PEM fastener holes).

- Automatic hole alignment across different planes, ensuring precision and uniformity.

Whether you’re designing ventilation slots, mounting points, or hardware accommodations, this feature speeds up the process by eliminating the need for repetitive manual work. Consistency is key in manufacturing, and the Sheet Metal Hole Command ensures that your design adheres to these principles without added effort.

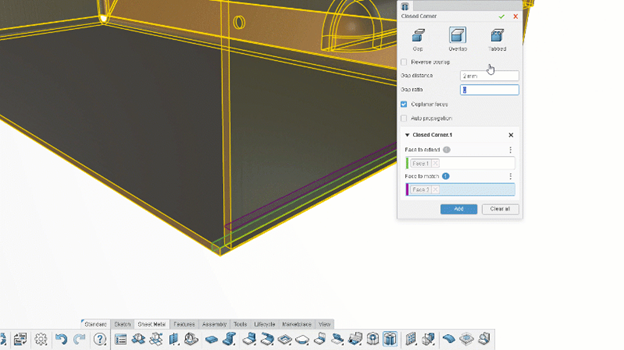

4. Closed Corner

The Closed Corner feature addresses the challenge of aligning overlapping flanges in sheet metal parts. This tool provides three distinct options:

- Gap: Define specific gap dimensions between flanges.

- Overlap: Close the gap entirely, creating a seamless finish.

- Tabbed: Close the gap while introducing a tab for additional structural support.

Clean, aligned corners are critical in applications like enclosures, cabinets, and frames. By automating the process of closing corners, this feature eliminates manual adjustments, ensuring your designs are production-ready.

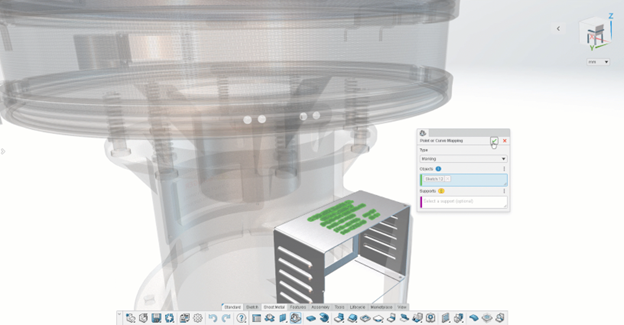

5. Point or Curve Mapping

Point or Curve Mapping is an invaluable feature for engineers who need to convey additional details in flat patterns. With this tool, you can map sketches, edges, curves, or points from the 3D design directly onto the flat pattern. This is especially useful for adding engravings, construction elements, or alignment marks.

These mapped details can be included in DXF exports, ensuring manufacturers have all the information needed for fabrication. Point or Curve Mapping enhances communication and reduces ambiguity in production workflows.

Why Choose 3D SheetMetal Creator?

3D SheetMetal Creator goes beyond the traditional capabilities of desktop CAD software. As a fully browser-based tool, it offers several unique advantages.

Cloud-Based Accessibility

Work from anywhere, anytime. With no need for complex installations or hardware requirements, designers can access 3D SheetMetal Creator from any device with an internet connection. This flexibility is perfect for hybrid work environments and global collaboration.

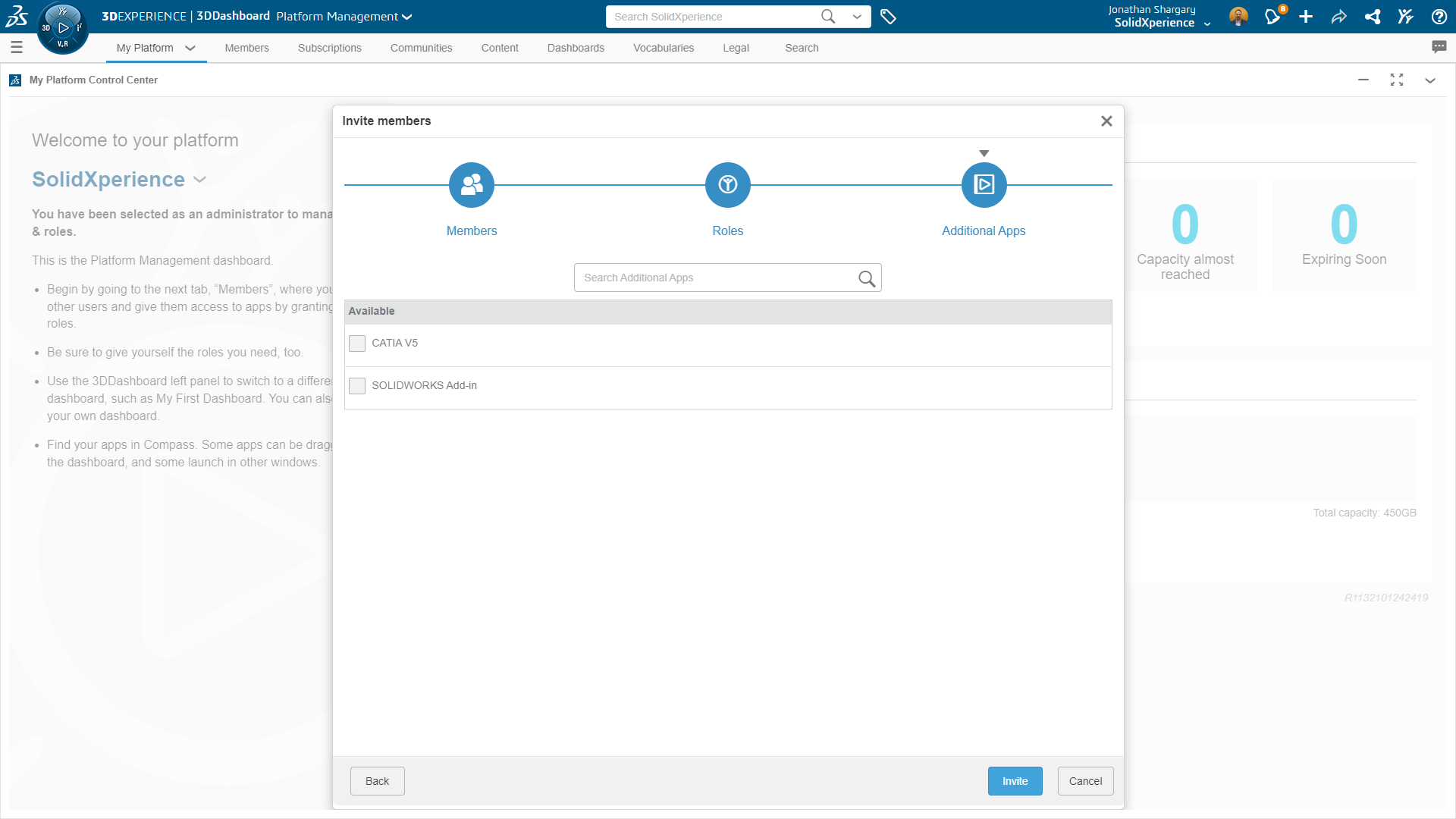

Seamless Integration with 3DEXPERIENCE Platform

As part of the 3DEXPERIENCE platform, 3D SheetMetal Creator integrates seamlessly with other tools like Collaborative Designer for SOLIDWORKS, SIMULIA for simulation, and ENOVIA for data management. This ecosystem allows teams to share data, track changes, and manage projects in real time.

Intuitive User Interface

The software is designed with ease of use in mind. Its intuitive interface ensures that both novice and experienced users can quickly adopt the tool without extensive training.

Automatic Updates

With cloud-based deployment, you’ll always have access to the latest features and updates. There’s no need for manual installations, ensuring your team remains productive with the most up-to-date tools.

Enhanced Collaboration

Teams can collaborate in real time, reviewing designs and providing feedback directly within the platform. This reduces the need for back-and-forth communication and accelerates decision-making.

Use Cases for 3D SheetMetal Creator

Industrial Equipment

Designers of industrial equipment rely on 3D SheetMetal Creator to create robust and precise components. Features like the Jog Command and Closed Corner tool are particularly useful for crafting enclosures, brackets, and frames.

Consumer Products

From kitchen appliances to electronics, consumer product designers use the Sheet Metal Hole Command to incorporate ventilation slots, mounting points, and hardware accommodations into their designs.

Automotive and Aerospace

The automotive and aerospace industries benefit from the software’s ability to handle complex geometries and optimize manufacturing processes. The Bend Order Table ensures clear communication of production steps, while Point or Curve Mapping adds critical details to flat patterns.

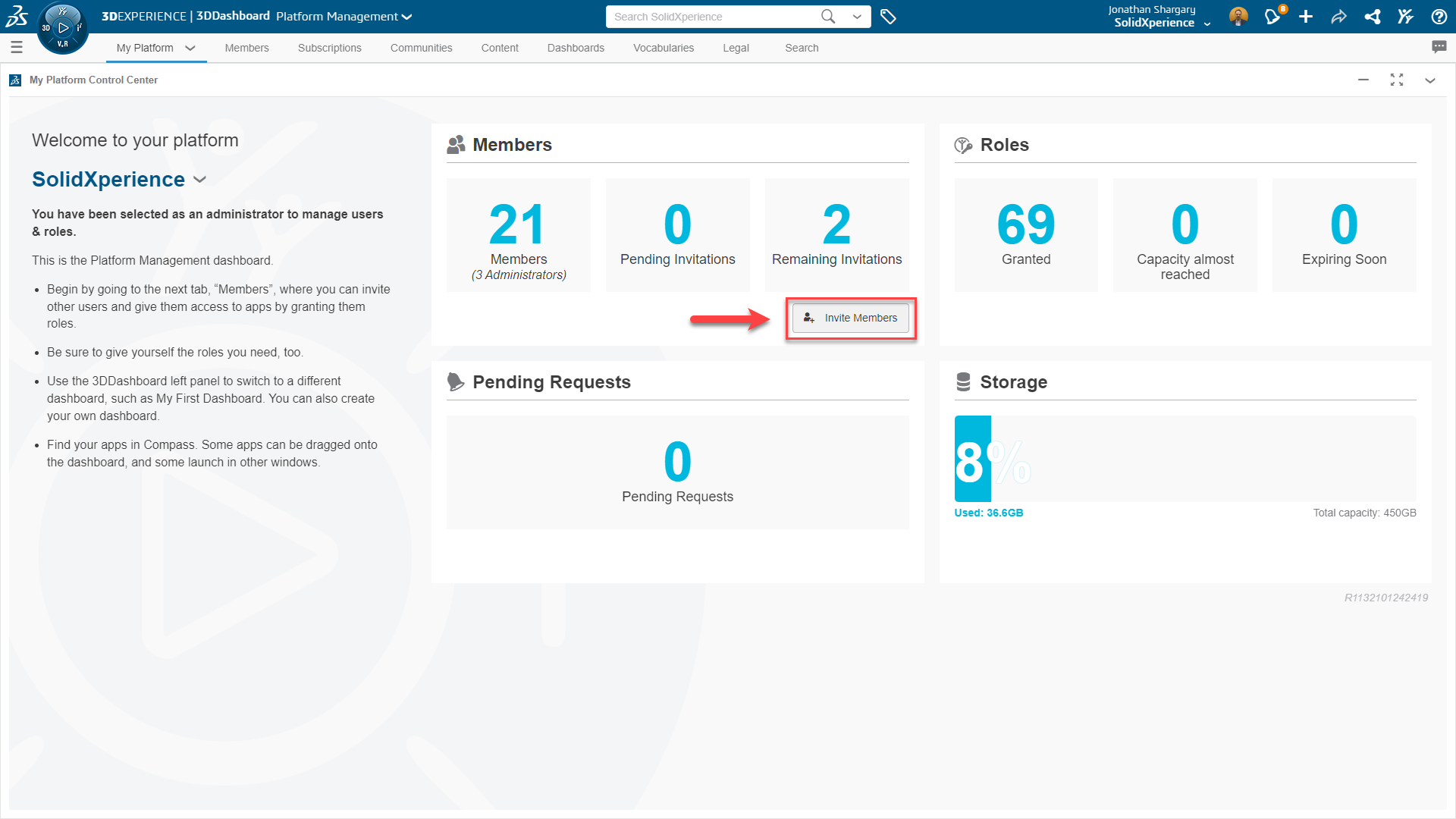

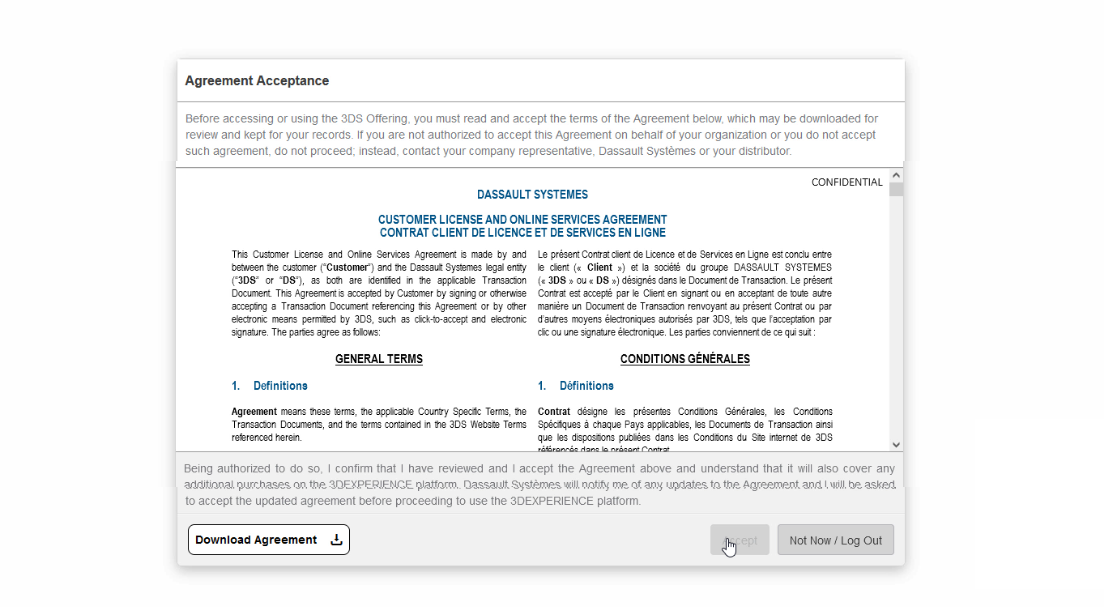

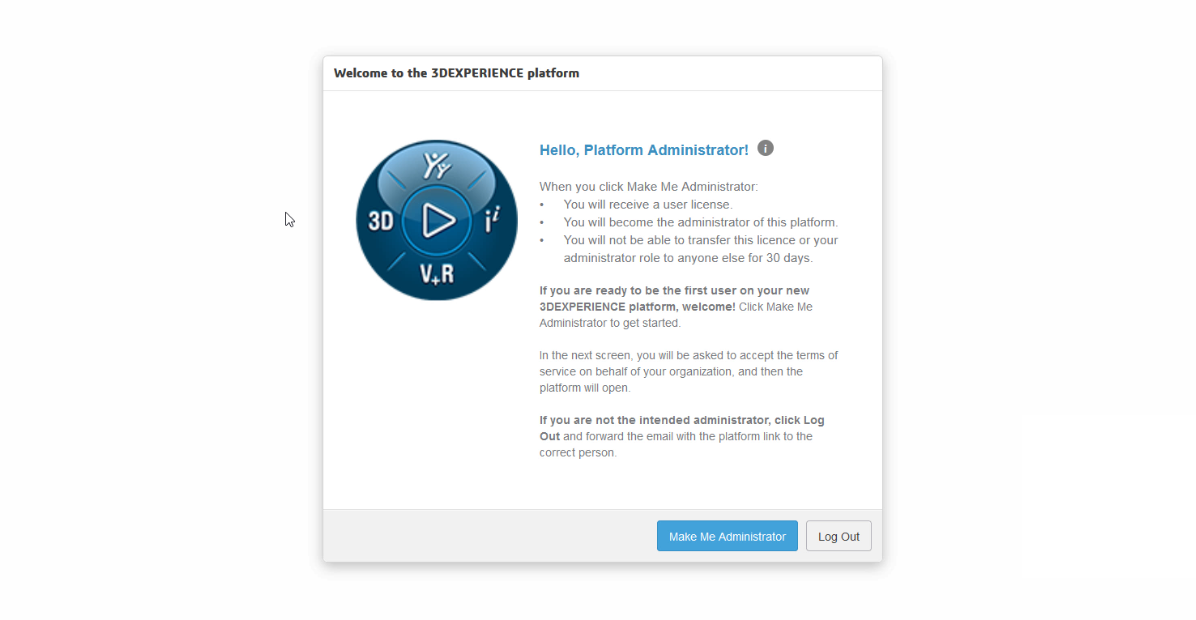

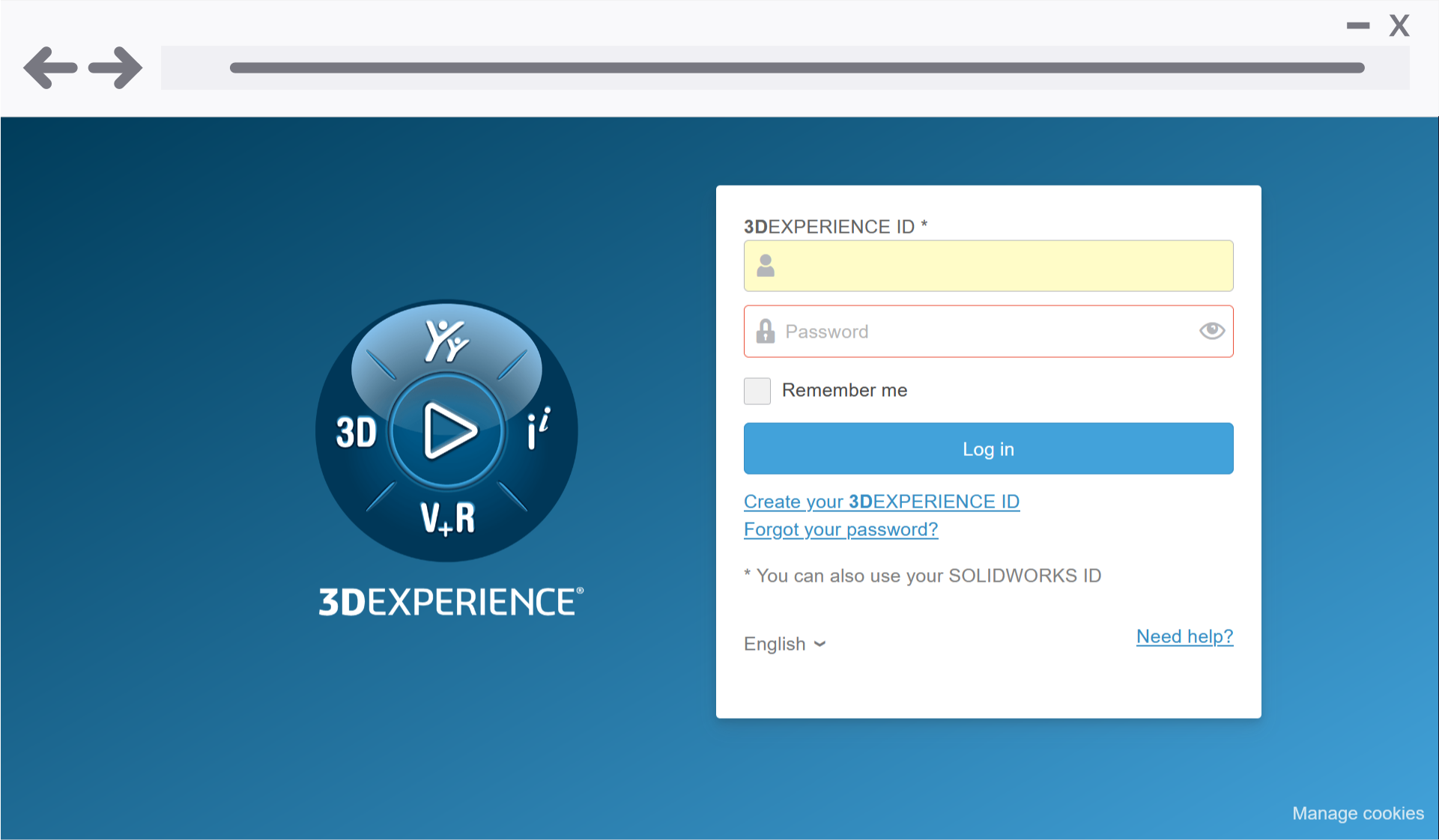

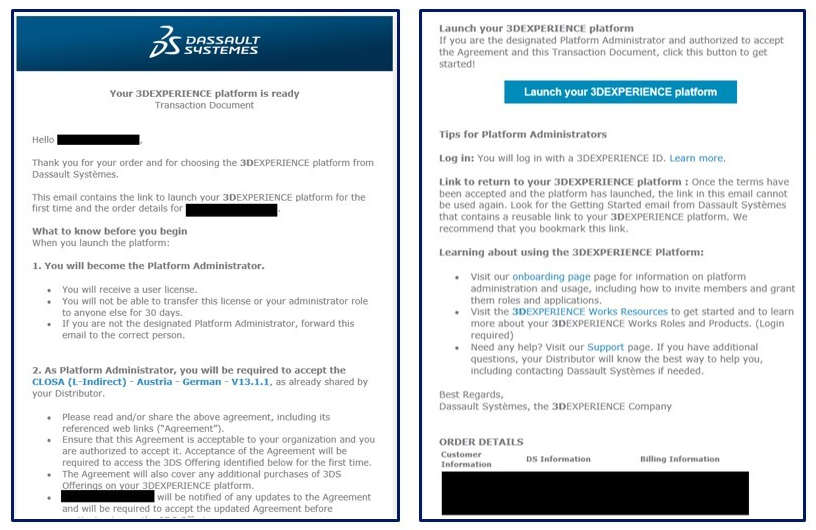

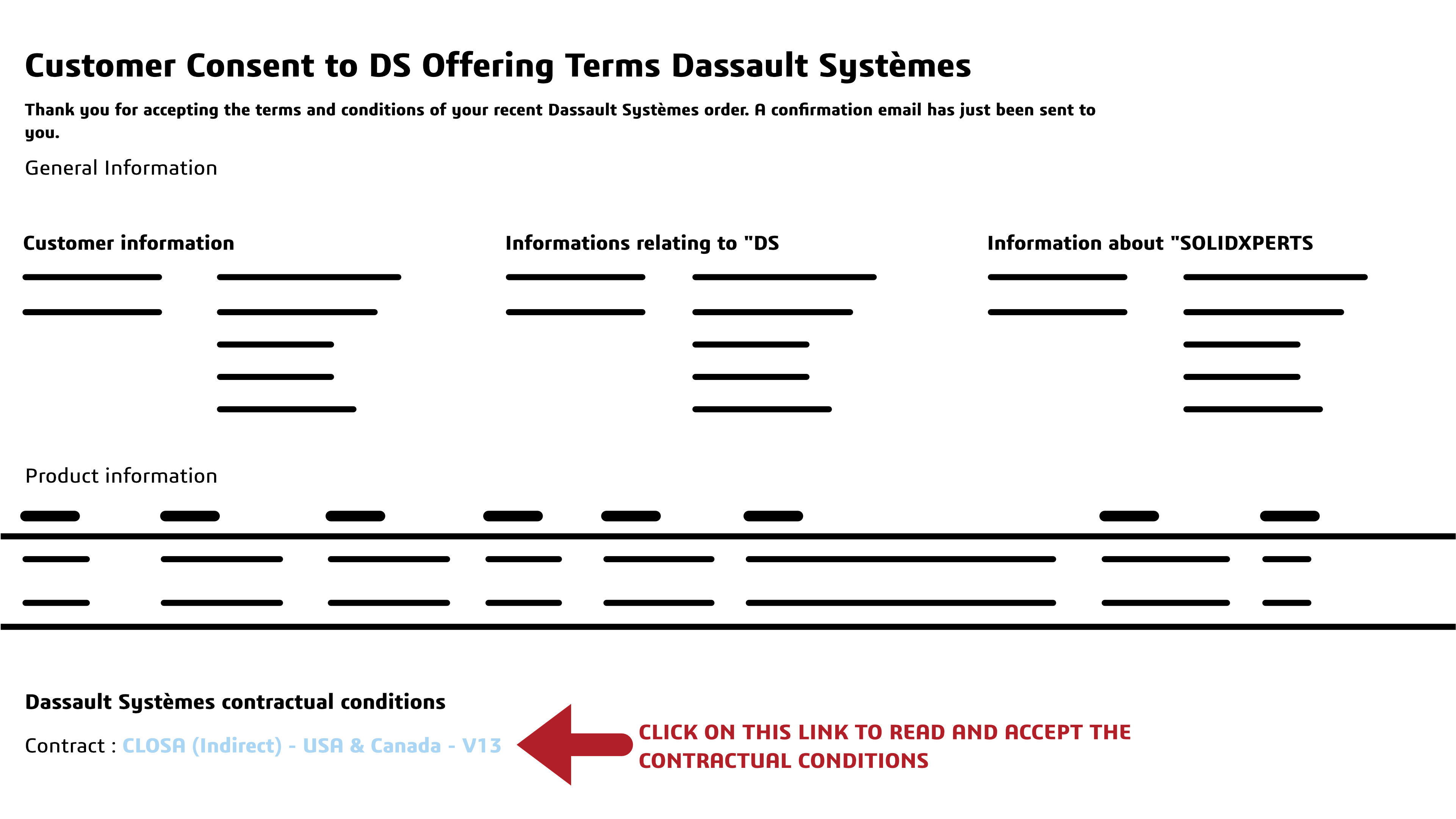

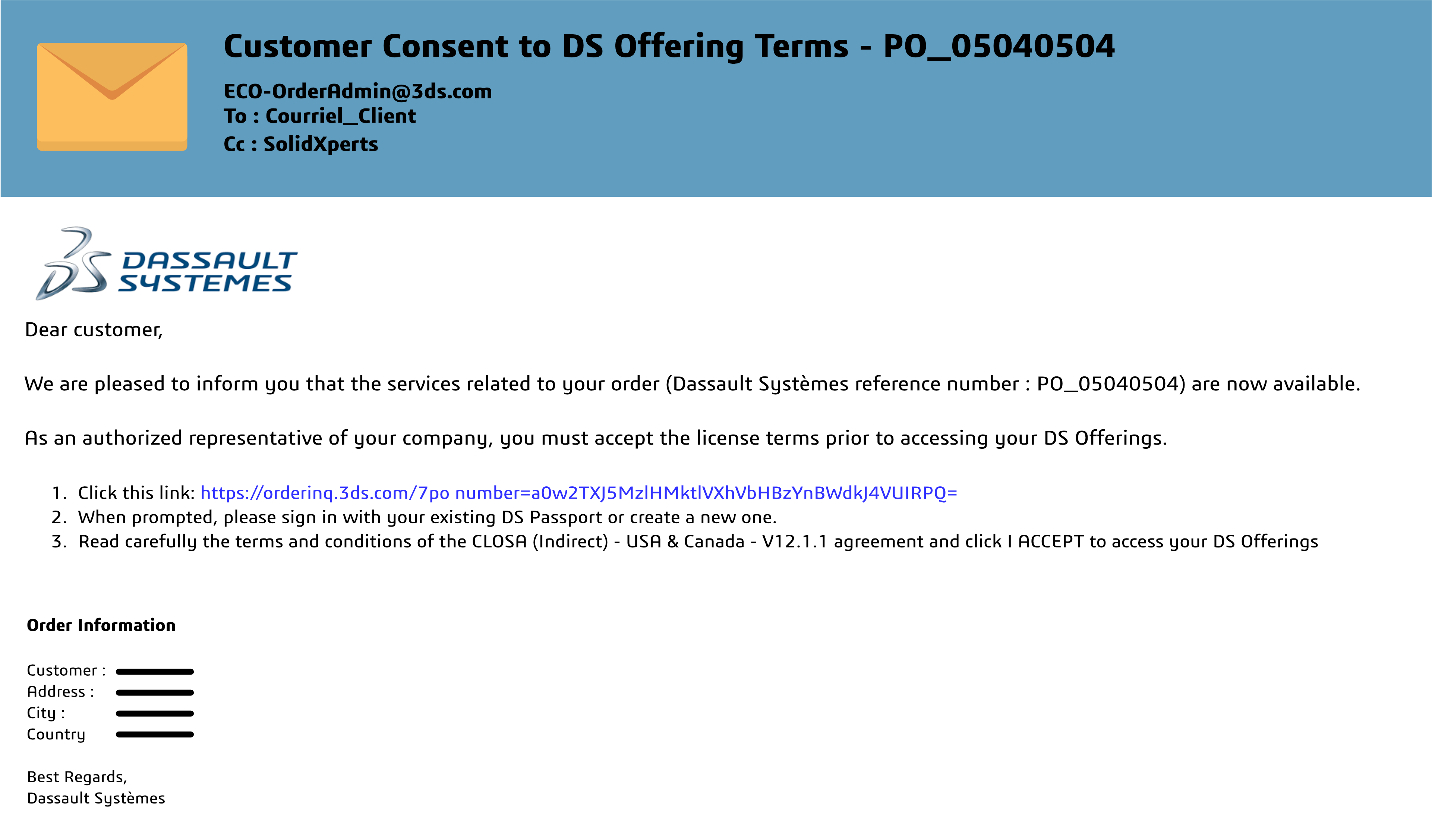

Getting Started with 3D SheetMetal Creator

If you’re ready to make your sheet metal projects easier and more efficient, Solidxperts is here to help. As an authorized reseller, we’ll provide you with the tools, training, and support you need to get started.

Contact us today to learn more about 3D SheetMetal Creator, or schedule a demo to see it in action. Let’s take your sheet metal designs to the next level together!