- SolidXperts, a full-service CAD and 3D printing solution provider, to offer full Nexa3D range of ultrafast, industrial resin 3D printers.

- Nexa3D resin printers deliver high print speeds without compromising accuracy or material stability to the dental, engineering, and product design industries.

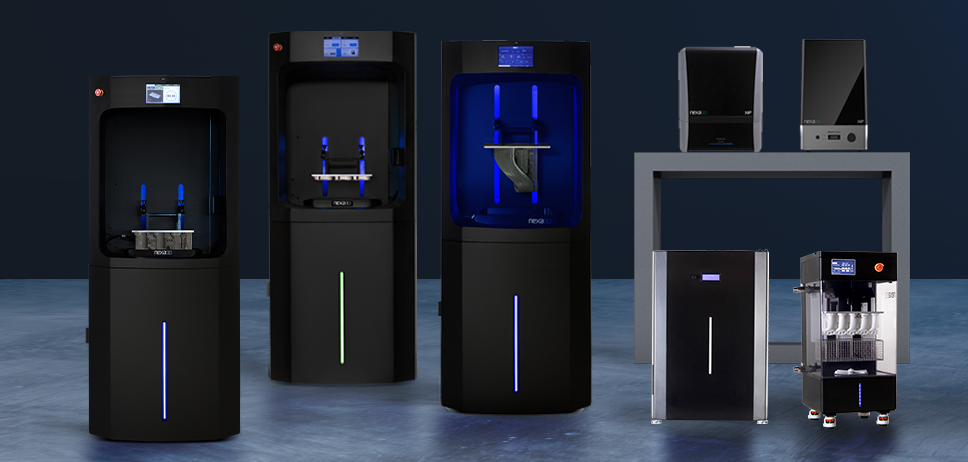

Quebec, CA, December 15, 2022 – SolidXperts is excited to announce a new partnership with Nexa3D®, a leading provider of ultrafast photopolymer 3D printers that offer high print speeds, smooth surface finishes, and reliable repeatability, all on an open material platform. SolidXperts will officially offer Nexa3D’s full range of resin highspeed 3D printers, including the XiP desktop printer and industrial NXE Pro series printers, to designers, engineers, and businesses across Quebec, Ontario, and New England U.S.A.

“My dad always said to me ‘Time is money,’ and that was the first thing that came to mind when I was introduced to the Nexa3D products. I have a routine when I leave the office at night, I always look into our Additive Manufacturing Lab to see what’s printing and then the next morning to see how far it’s gotten. Now, with ultrafast Nexa3D printers, I’ll have to change my routine. I am truly thrilled to be partnering with Nexa3D on our Additive Manufacturing journey.”

-Alex Habrich, CEO and Founder of the SolidXperience Group

SolidXperts offers a comprehensive 3D design product portfolio that helps companies and engineers move seamlessly from conception to production by leveraging industry leading CAD software and a full range of 3D printers and scanners. Nexa3D printers enable manufacturers and designers to achieve better print quality and up to 20x productivity gains in-house, using patented LSPc® (Lubricant Sublayer Photo-curing) technology, that is significantly faster than traditional stereolithography and digital light processes.

“Nexa3D is thrilled to partner with SolidXperts to make our technology even more accessible to the Quebec, Ontario and New England regions. Their team is strong, with significant knowledge of 3D printing solutions, and they have built an incredible relationship with their customers over the last 25 years founded on trust and exceptional service.”

-Patrick Sullivan, Vice President and General Manager of Industrial Products at Nexa3D

As an authorized reseller, SolidXperts proudly offers not only a comprehensive product portfolio of curated 3D printing options, but also offers printer materials, technical support, training, learning resources, consulting, and 3D design and printing services. Browse products and services, or reach out to the Xperts directly.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

“It feels like drowning is”, the most common report from the COVID-19 patients requiring breathing assistance, and with that imagery, we took inspiration from the simplicity of a scuba breathing apparatus. The SolidXperience Group officially began tackling the problem on March 23rd, ready to help save the world however they could.

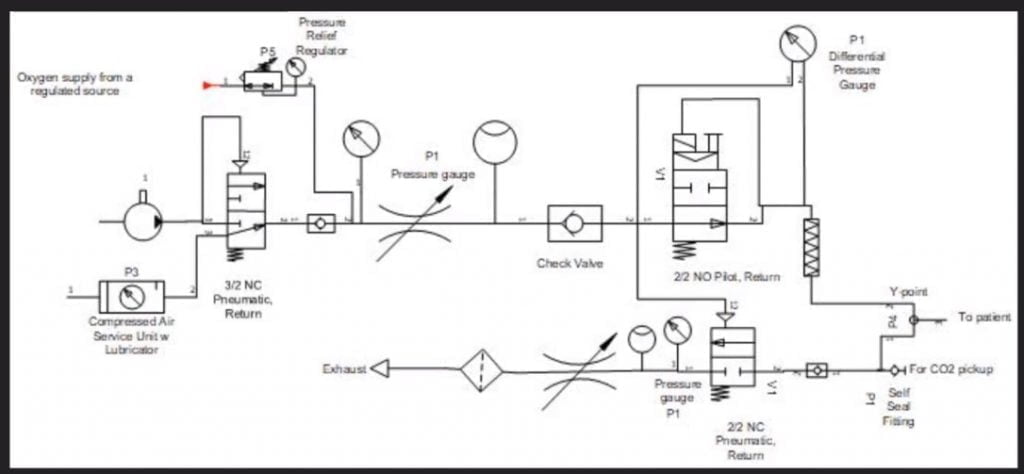

“It feels like drowning is”, the most common report from the COVID-19 patients requiring breathing assistance, and with that imagery, we took inspiration from the simplicity of a scuba breathing apparatus. The SolidXperience Group officially began tackling the problem on March 23rd, ready to help save the world however they could. The next step was to analyze the given product specifications and start creating schematic diagrams defining the required parts and showing how those parts interact to create the desired results. With the help of the project’s panel of medical advisors, the group was able to take the initial schematic designs and modify them as a collaborative team. All online!

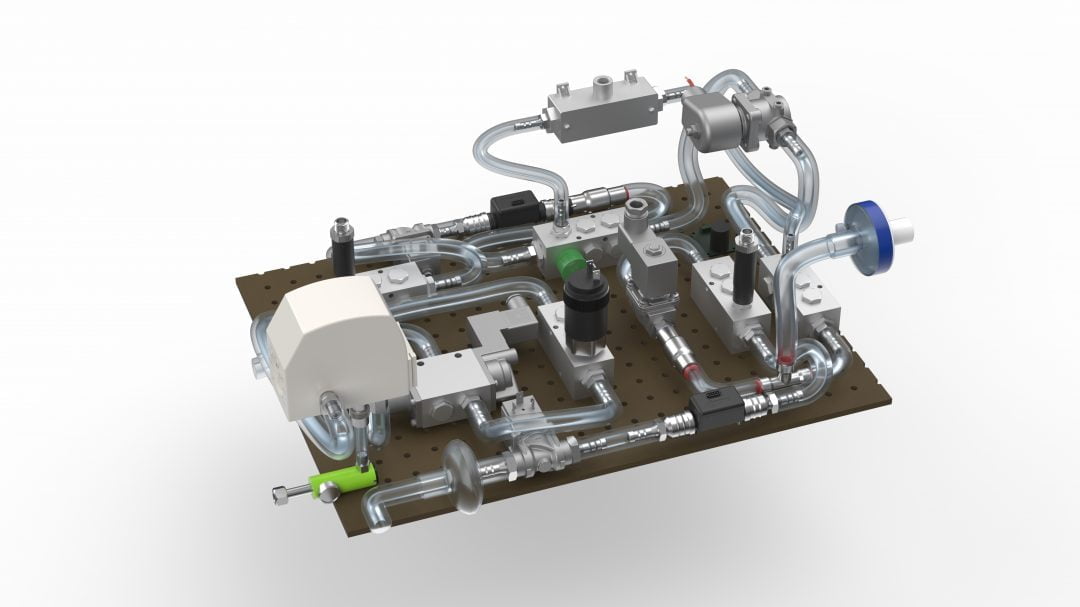

The next step was to analyze the given product specifications and start creating schematic diagrams defining the required parts and showing how those parts interact to create the desired results. With the help of the project’s panel of medical advisors, the group was able to take the initial schematic designs and modify them as a collaborative team. All online! Next, packaging: getting all the required components to fit into a manageable, transportable, robust, easy-to-operate, and reliable case. Under the pressure of the CODE LIFE contest entry submission date of March 31st, this process was successfully started and completed on March 30th. Concurrently, the digital interface was coded to manage the internal valves, solenoids, and sensors necessary to provide a clear and secure on/off readout and warning alarms.

Next, packaging: getting all the required components to fit into a manageable, transportable, robust, easy-to-operate, and reliable case. Under the pressure of the CODE LIFE contest entry submission date of March 31st, this process was successfully started and completed on March 30th. Concurrently, the digital interface was coded to manage the internal valves, solenoids, and sensors necessary to provide a clear and secure on/off readout and warning alarms. The fight isn’t over yet, however! In the coming weeks, several more steps need to be taken quickly to meet the hopeful deadline of May 1st for a functioning prototype. As the physical pieces of the first construction are gathered the interface code must be tested and refined, and the assembly must go through a series of tests and simulations to determine that it meets pre-set standards and can be labeled ‘medical grade’.

The fight isn’t over yet, however! In the coming weeks, several more steps need to be taken quickly to meet the hopeful deadline of May 1st for a functioning prototype. As the physical pieces of the first construction are gathered the interface code must be tested and refined, and the assembly must go through a series of tests and simulations to determine that it meets pre-set standards and can be labeled ‘medical grade’.