TL;DR

SOLIDWORKS 2025 delivers an array of new features designed to enhance collaboration, streamline workflows, and elevate design precision. This latest release integrates advanced tools for real-time team connectivity, boosts performance for complex assemblies, and introduces smarter part modeling techniques. Users can also expect improvements in detailing, immersive rendering, and ECAD-MCAD collaboration, ensuring their projects meet the highest standards of efficiency and innovation.

With seamless integration into the 3DEXPERIENCE platform, SOLIDWORKS 2025 sets the stage for a new era of connected design and data management. Whether you’re optimizing workflows or exploring new creative possibilities, this release is tailored to help you achieve more in less time.

Intro

The wait is over—SOLIDWORKS 2025 is here, and it’s designed to push the boundaries of what’s possible in engineering and design. Packed with advanced tools and updates, this release focuses on enhancing collaboration, boosting performance, and delivering precision across every phase of the design-to-production journey.

At Solidxperts, we believe that staying ahead of industry trends means adopting tools that not only keep up but help you lead. With SOLIDWORKS 2025, you’ll find smarter workflows, new levels of connectivity, and features that empower you to take your ideas further.

This blog marks the beginning of a multi-part series, where we’ll dive deeper into the newest features of SOLIDWORKS 2025 over the coming weeks. From part modeling to assembly performance, collaboration tools, and more, we’ll explore how these updates can elevate your projects and streamline your workflows.

Let’s dive into the highlights of what’s new in SOLIDWORKS 2025.

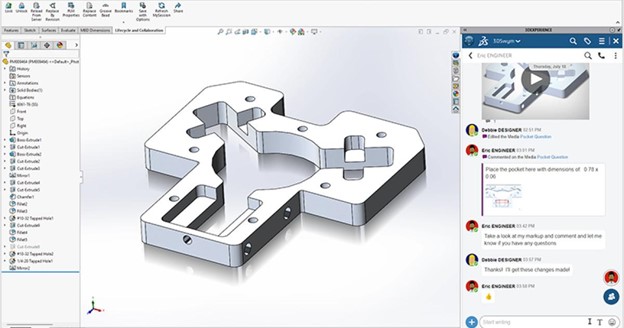

Collaboration Without Boundaries

Innovation thrives in collaboration, and SOLIDWORKS 2025 takes team connectivity to new heights. With improved integration and real-time updates, your projects stay on track—even when your team is working remotely.

What’s New

- Instant Updates: Get real-time notifications on file changes, ensuring your team always works with the latest versions, preventing costly errors.

- Connected Communities: Share insights, ask questions, and discuss designs directly within the platform—no more juggling external tools.

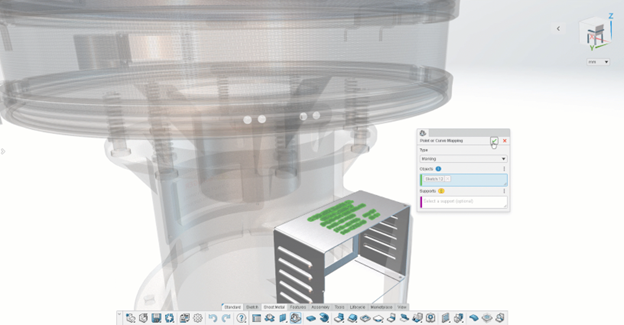

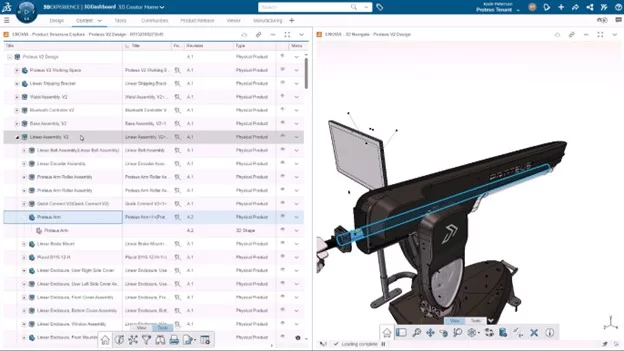

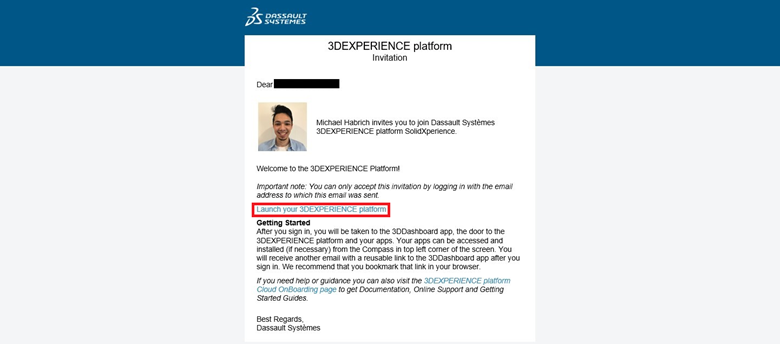

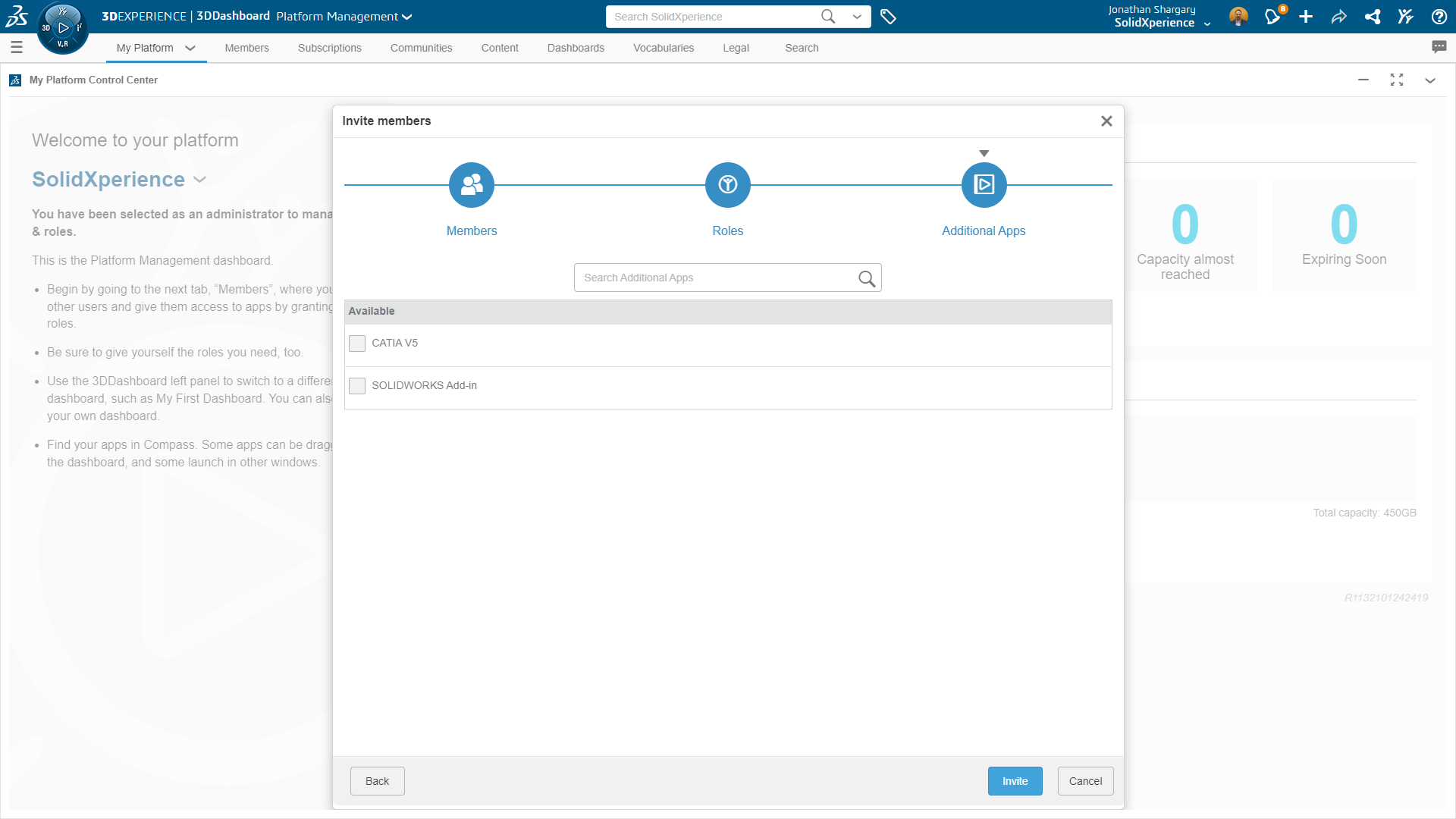

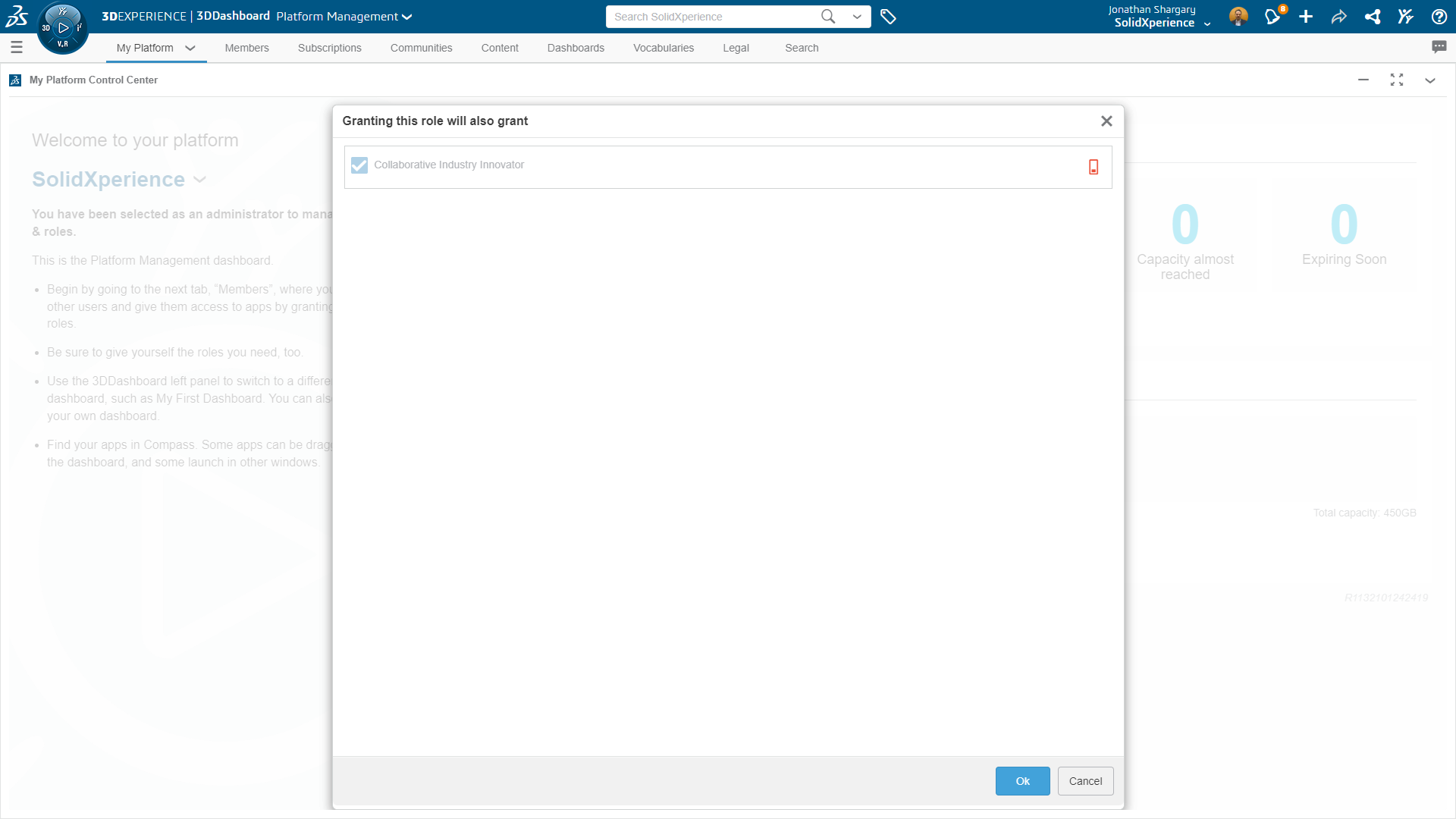

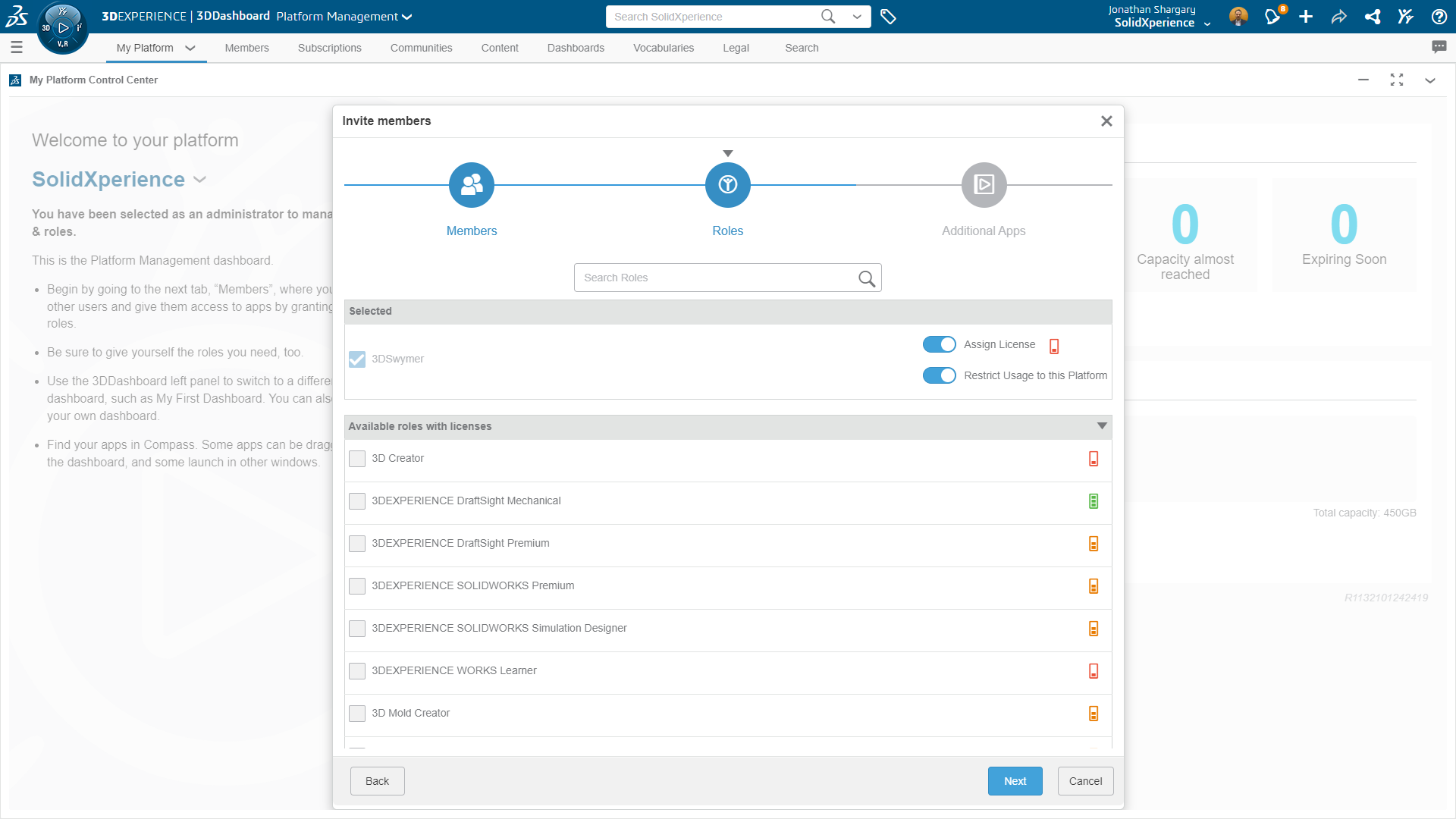

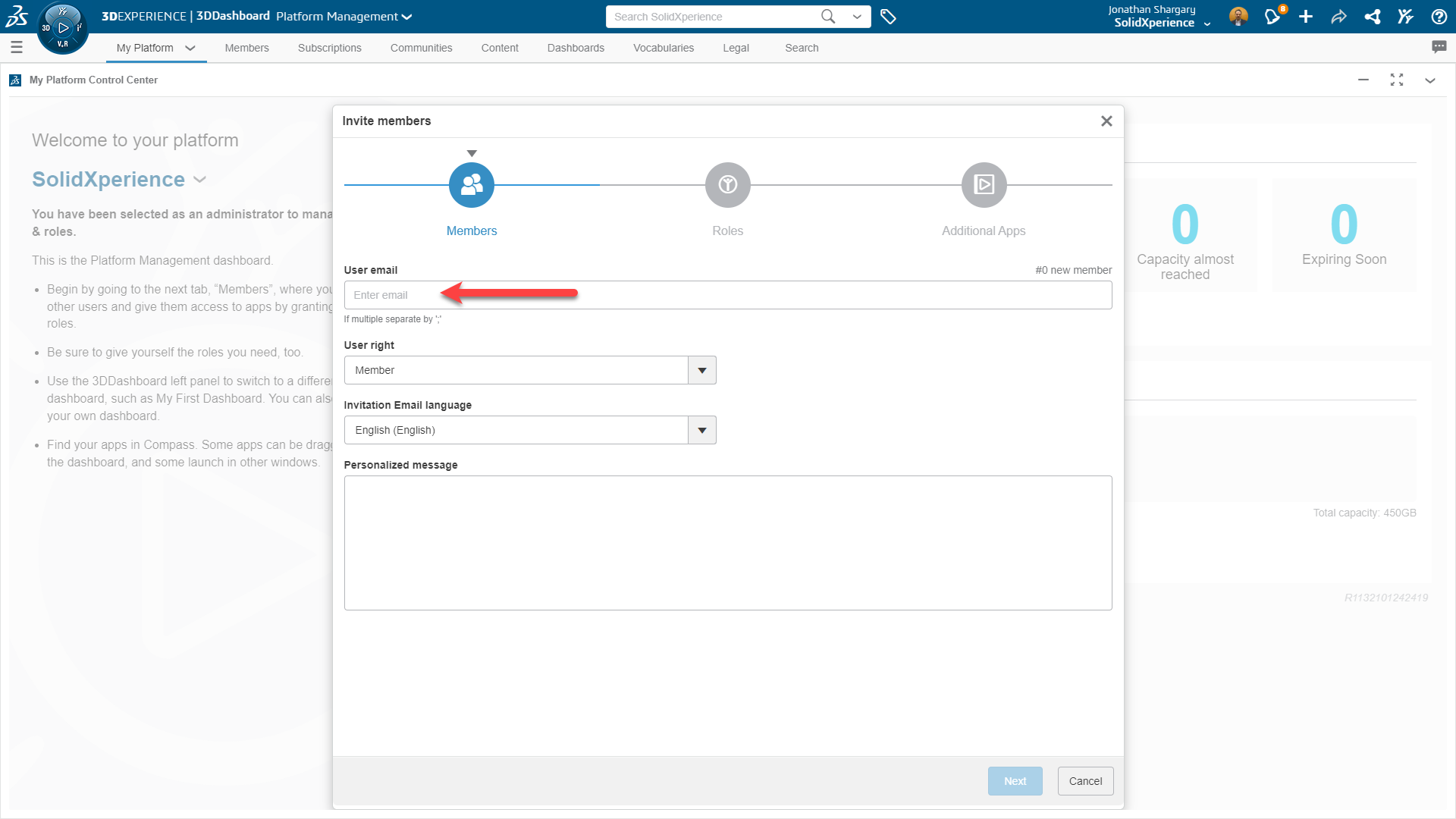

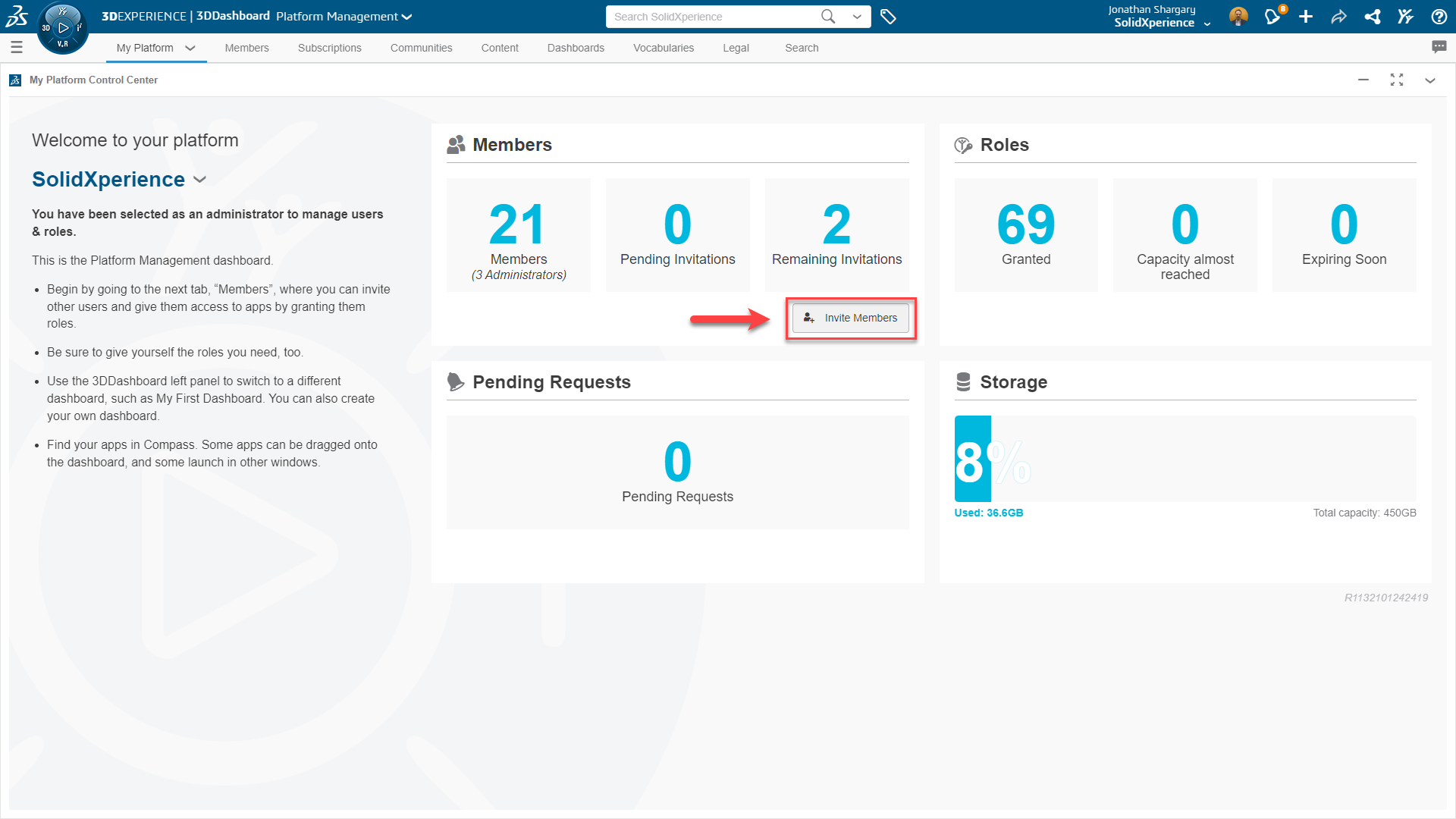

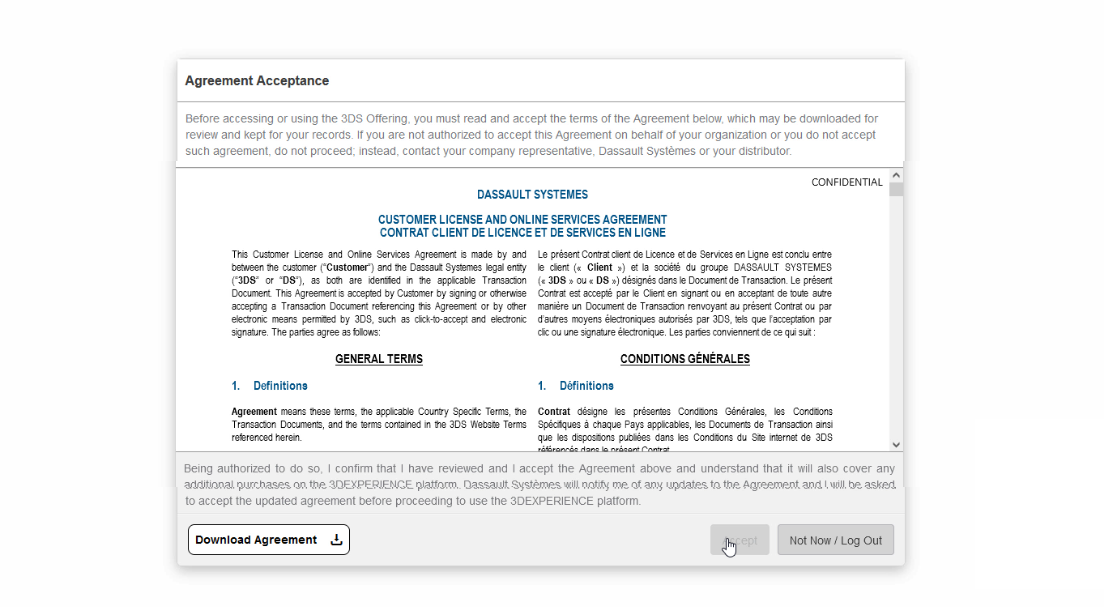

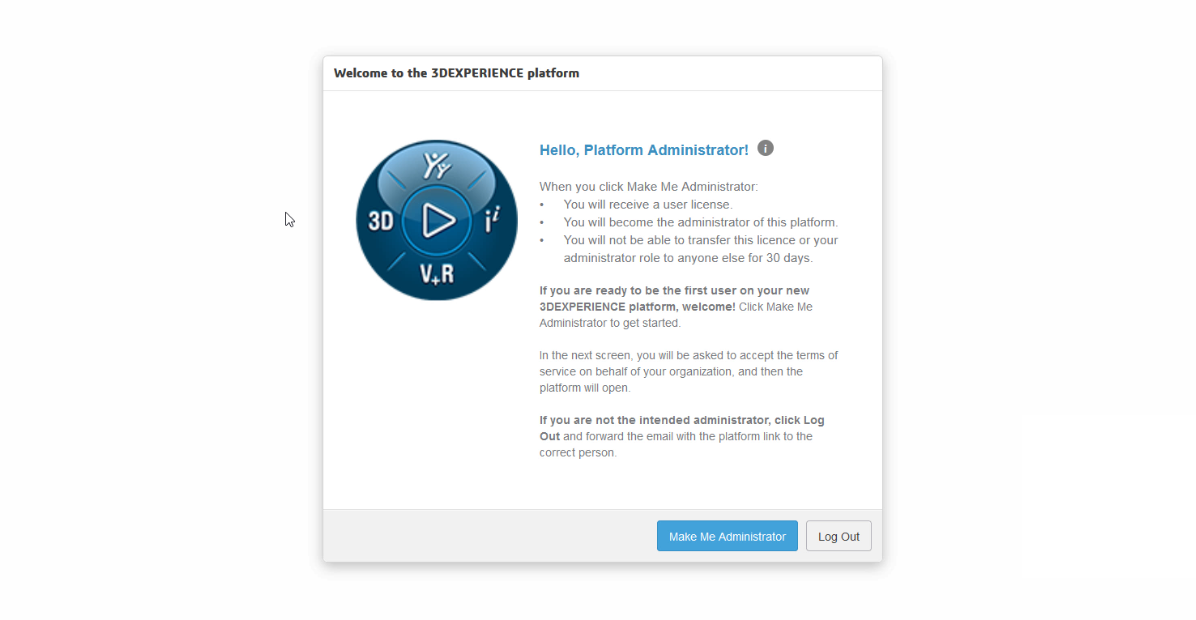

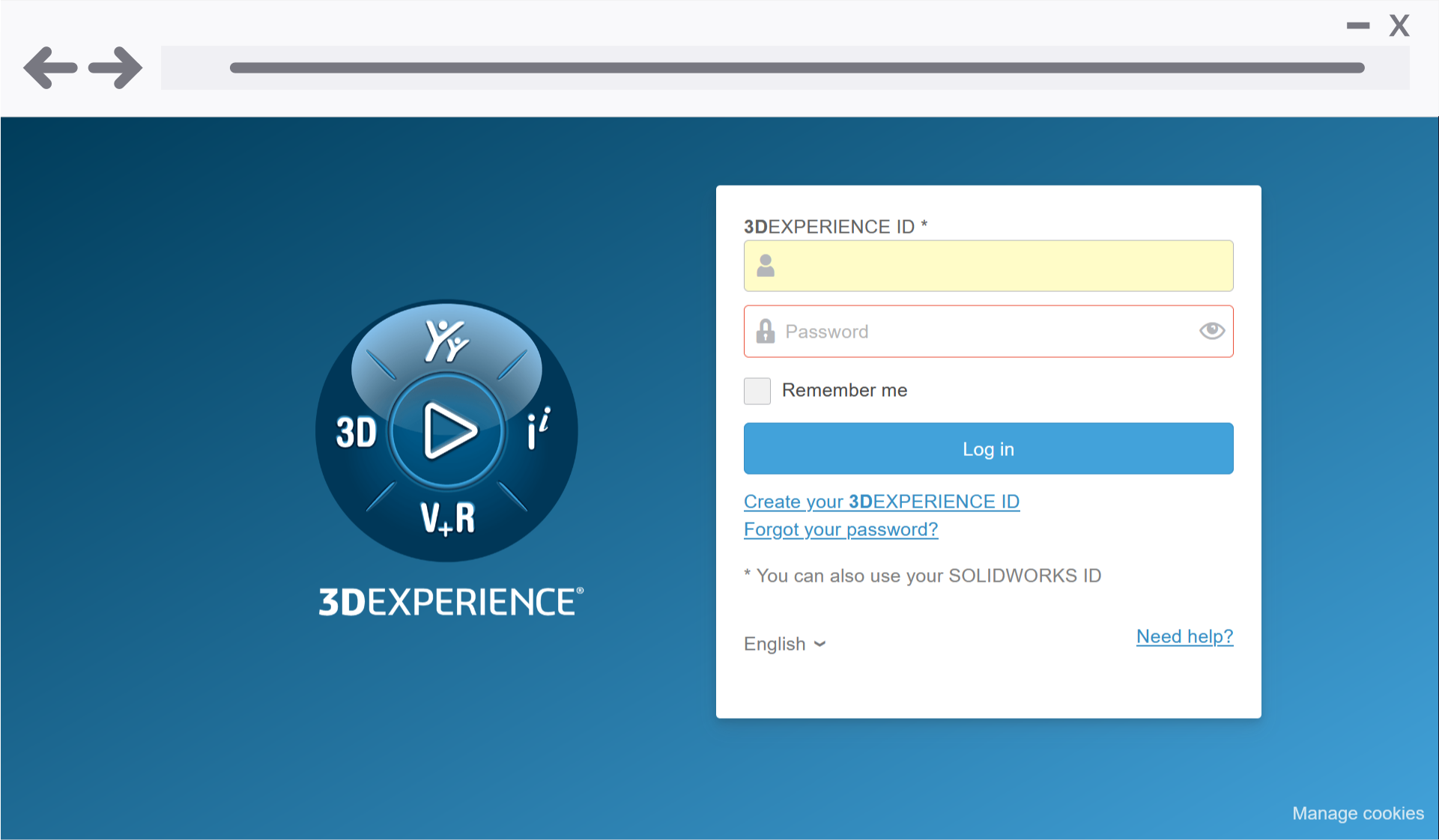

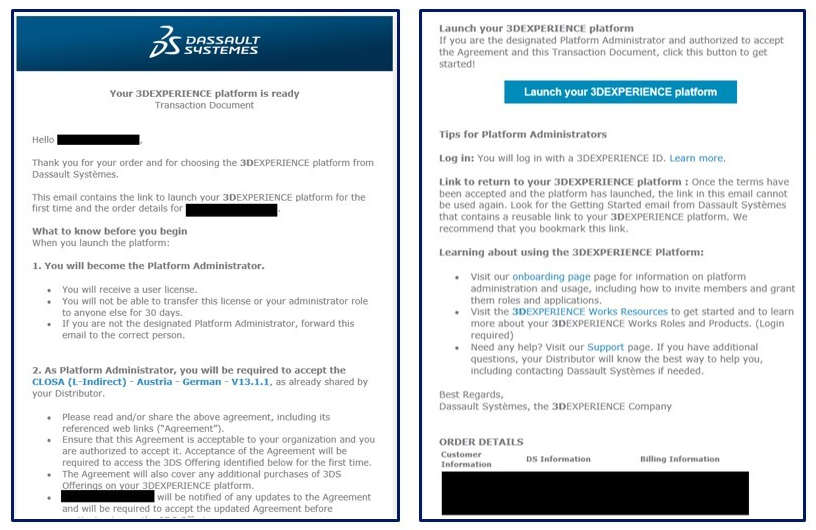

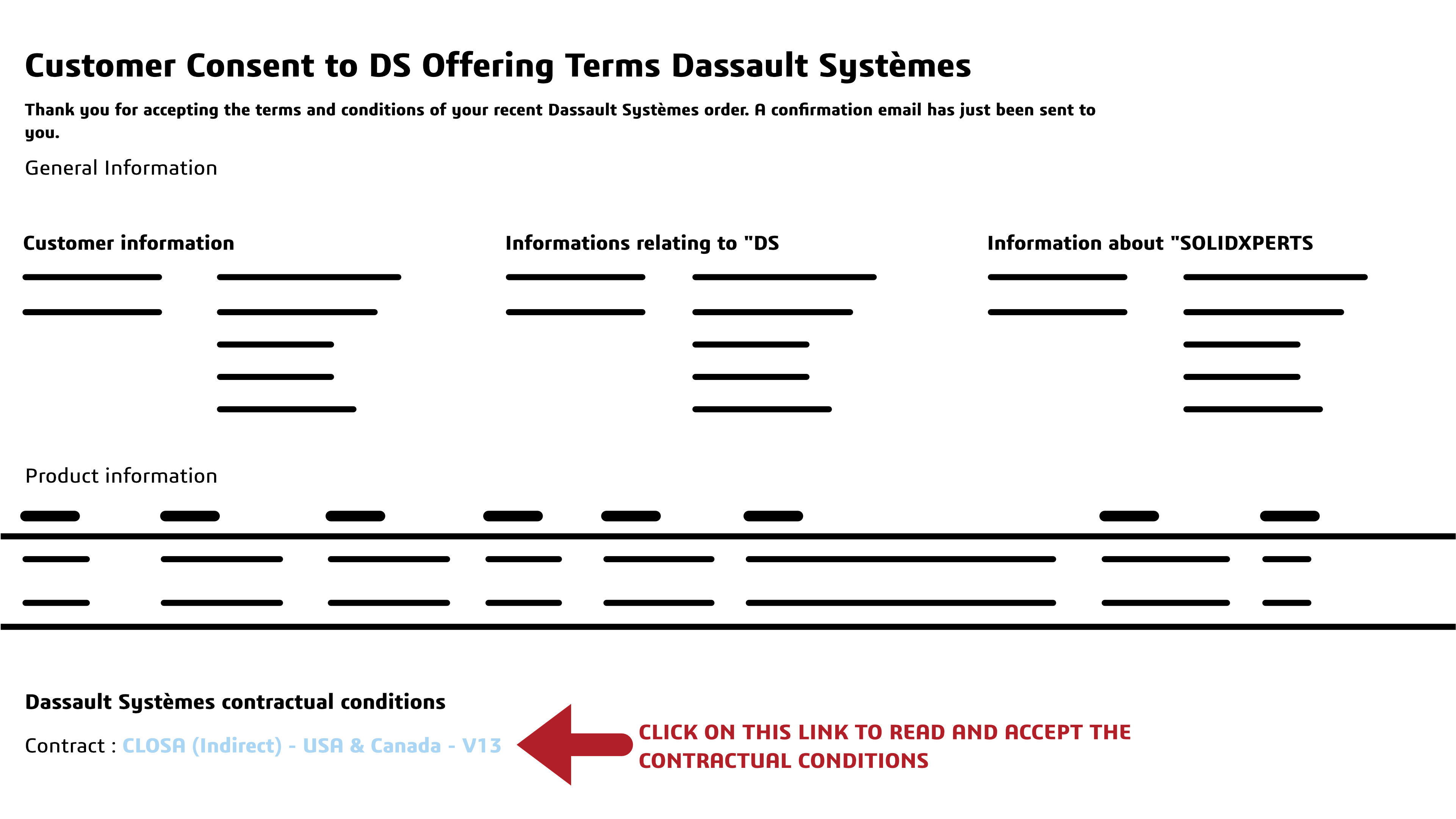

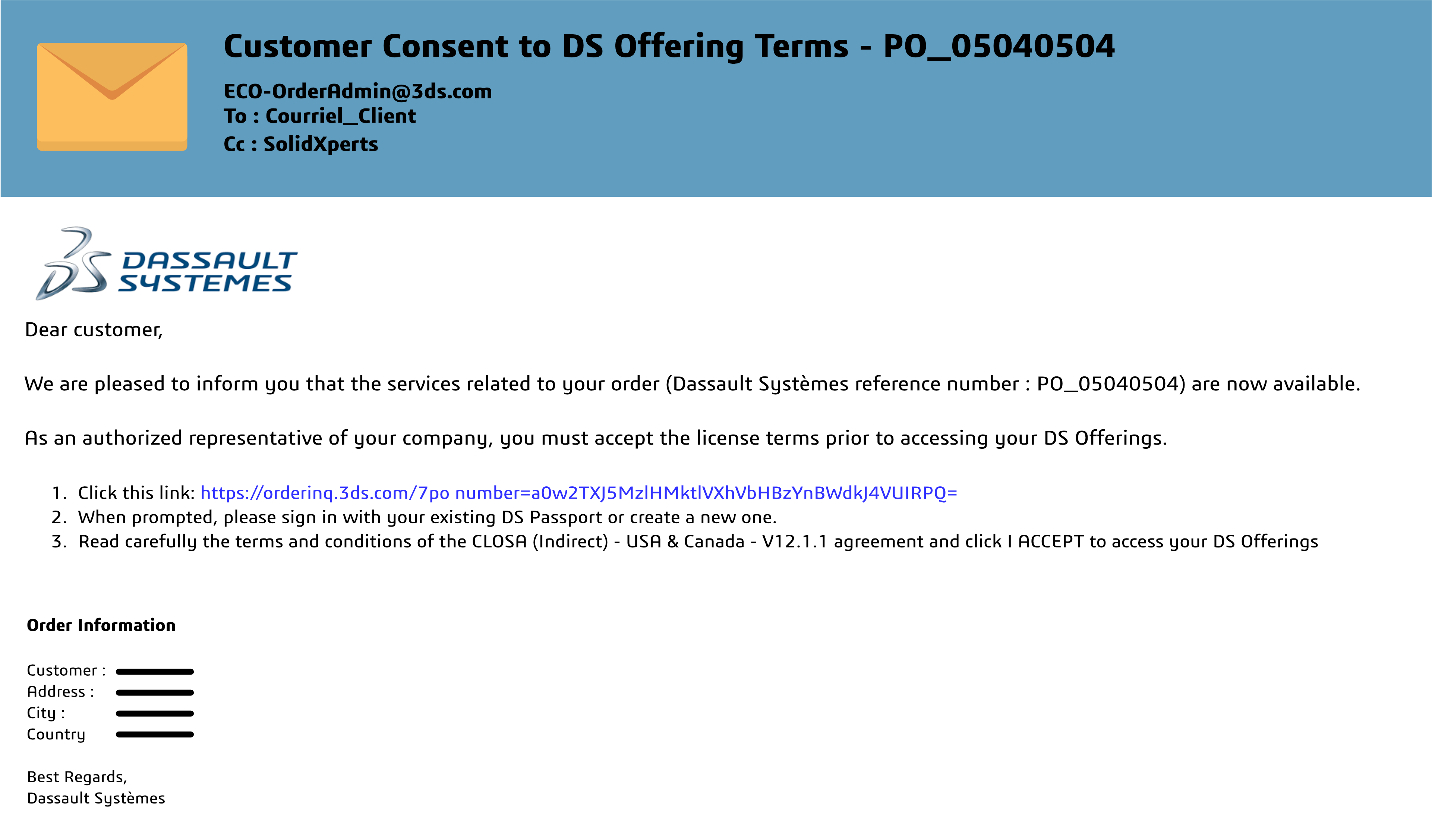

- 3DEXPERIENCE PDM Integration: Leverage the power of SOLIDWORKS PDM combined with the 3DEXPERIENCE platform for robust data management and collaborative design.

Why It Matters

Collaboration tools in SOLIDWORKS 2025 streamline communication and ensure everyone, from engineers to stakeholders, stays on the same page. Say goodbye to wasted time and hello to connected productivity.

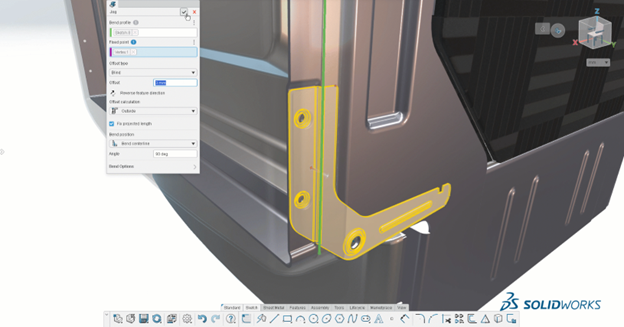

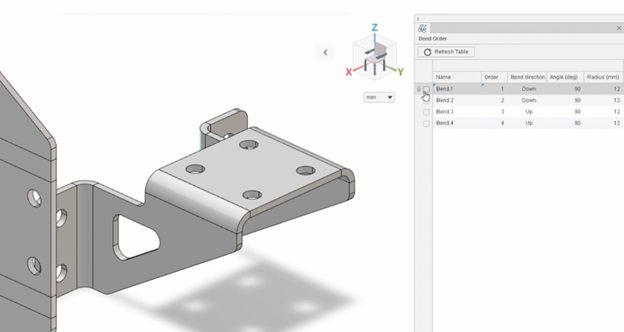

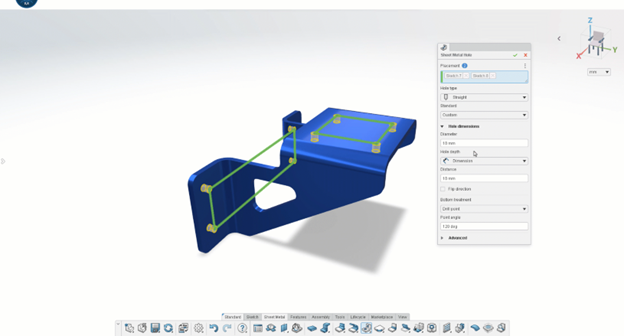

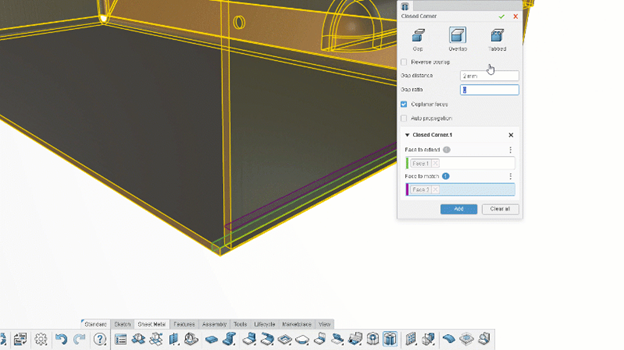

Precision in Every Part

Design is in the details, and the latest part modeling enhancements in SOLIDWORKS 2025 make achieving precision easier than ever. These updates are designed to reduce manual effort while expanding your creative possibilities.

What’s New

- Chamfer Command Accelerators: Select edges faster with intuitive accelerators that save time on repetitive tasks.

- Variable Fillets: Create fluid, smooth transitions between edges with continuous blending capabilities.

- Sheet Metal Efficiency: Automatically generate bend notches on flat patterns for quicker and more accurate manufacturing setups.

- Silhouette Defeature: Simplify complex parts for large assemblies while keeping them linked to the original geometry.

Why It Matters

These tools allow you to focus on design innovation while minimizing repetitive tasks. The new modeling features ensure your designs are not only functional but also manufacturable, saving time and resources down the line.

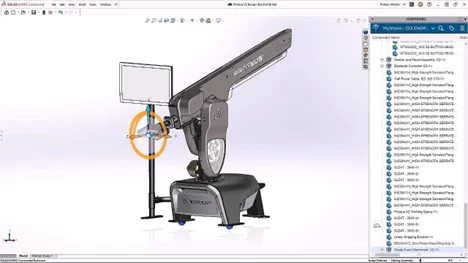

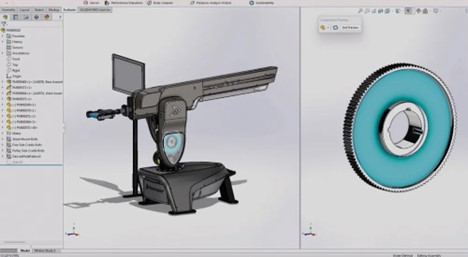

Assembly Performance Redefined

When working with large assemblies, every second counts. SOLIDWORKS 2025 introduces performance improvements that help you manage complex designs with speed and precision.

What’s New

- Top-Level SpeedPak Configurations: Add SpeedPak configurations directly to the top level of assemblies without editing subassemblies.

- Faster Mass Properties Calculations: Pre-calculated values for parts streamline mass property analyses in assemblies.

- Interference Detection: Identify clashes between surface and solid bodies—even in Large Design Review mode.

Why It Matters

SOLIDWORKS 2025 empowers you to handle massive assemblies efficiently, helping you make decisions faster and maintain tight project timelines.

Elevated Drawing and Detailing

Great designs require clear documentation. With SOLIDWORKS 2025, creating and refining detailed drawings is faster and more intuitive, ensuring your team and partners can bring concepts to life seamlessly.

What’s New

- Multi-Approval Stamps: Enforce company rules and add approval stamps on connected devices for better control and accountability.

- Custom BOM Quantities: Tailor BOM tables to display QUANTITY or LENGTH x QUANTITY based on your project needs.

- Streamlined Layouts: Automatic placement of tables, dimensions, and annotations creates cleaner, more readable drawings.

Why It Matters

Time spent on creating, adjusting, and organizing drawings is now significantly reduced, allowing you to focus on delivering high-quality designs.

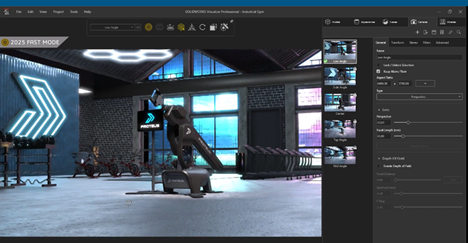

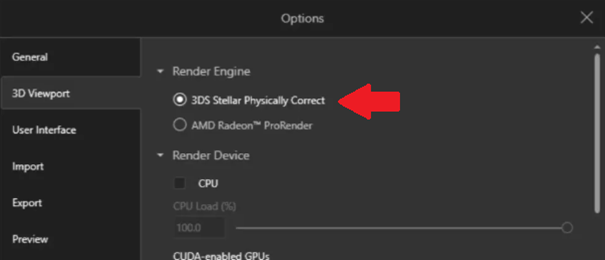

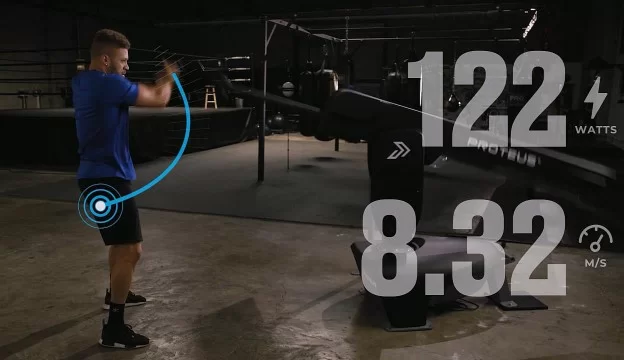

A Visual Revolution with Immersive Rendering

Captivating visuals are key to bringing your designs to life, and SOLIDWORKS 2025 is raising the bar with cutting-edge rendering features for Visualize.

What’s New

- Automated Rendering: Automate photorealistic renderings using the SOLIDWORKS Visualize API.

- Vulkan API Ray Tracing: Leverage advanced GPU technology for real-time, interactive ray tracing that produces stunning visuals faster.

Why It Matters

These enhancements ensure you can present your designs with confidence, whether you’re pitching to stakeholders or showcasing ideas to customers.

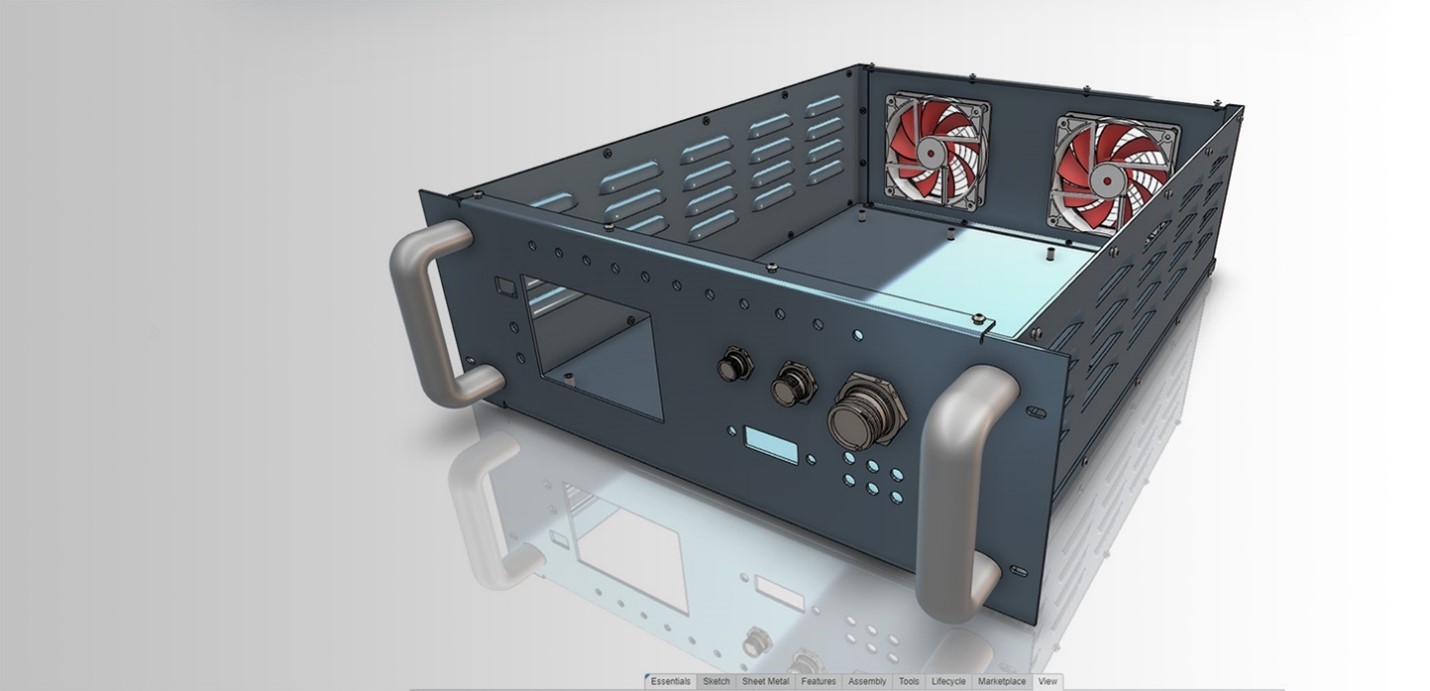

Bridging the Gap Between ECAD and MCAD

For products that merge mechanical and electronic components, SOLIDWORKS 2025 introduces tools to ensure seamless integration between ECAD and MCAD workflows.

What’s New

- Detailed PCB Imports: Include internal and external copper features in PCB designs for accurate mass and thermal analyses.

- CircuitWorks for All: Now universally available, CircuitWorks simplifies ECAD-MCAD collaboration.

Why It Matters

By bridging these traditionally siloed workflows, SOLIDWORKS 2025 enables teams to produce better designs in less time.

Why Choose SOLIDWORKS 2025?

SOLIDWORKS 2025 isn’t just an update; it’s a toolkit for success in a fast-paced, connected world. From collaborative tools to enhanced performance and precision, this version empowers you to deliver designs that stand out.

At Solidxperts, we’re here to help you unlock the full potential of SOLIDWORKS 2025. Our team of experts is ready to guide you through its features, ensure a smooth transition, and provide ongoing support.

Ready to Dive Deeper?

For an in-depth look at these design, collaboration, and data management features and enhancements, download the full PDF guide here.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action!

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action! Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies.

Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies. Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC.

Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC. Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.

Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.