Streamline CNC Programming with NC Shop Floor Programmer

Efficiency drives success in today’s manufacturing landscape, where competition demands precision and speed. The NC Shop Floor Programmer role on the 3DEXPERIENCE platform is a powerful solution that helps manufacturers meet these demands. By enabling you to create optimized NC programs tailored for a wide range of operations, such as milling and toolpath creation, this role ensures accurate machining while reducing production delays and the risk of unexpected issues.

Its features are not limited to creating efficient workflows—they also provide unmatched accuracy in toolpath simulation and program validation. With the ability to seamlessly handle complex NC machine operations, Shop Floor Programmer becomes an essential asset for anyone looking to streamline production and reduce costs.

What Is NC Shop Floor Programmer on the 3DEXPERIENCE Platform?

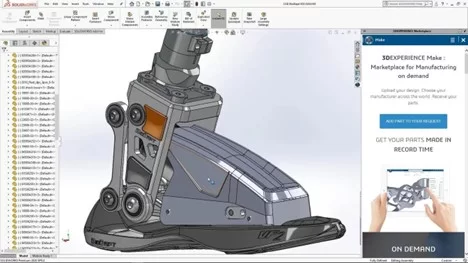

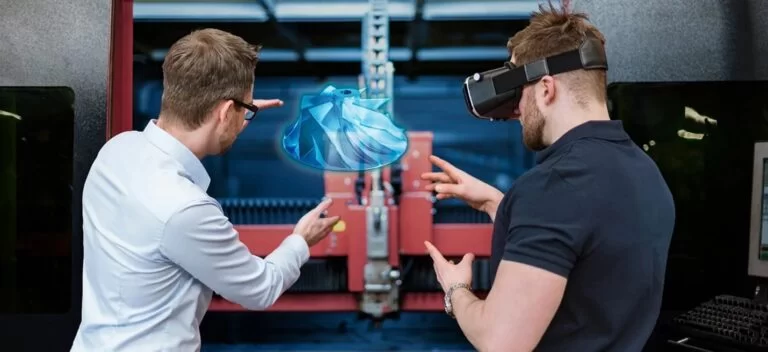

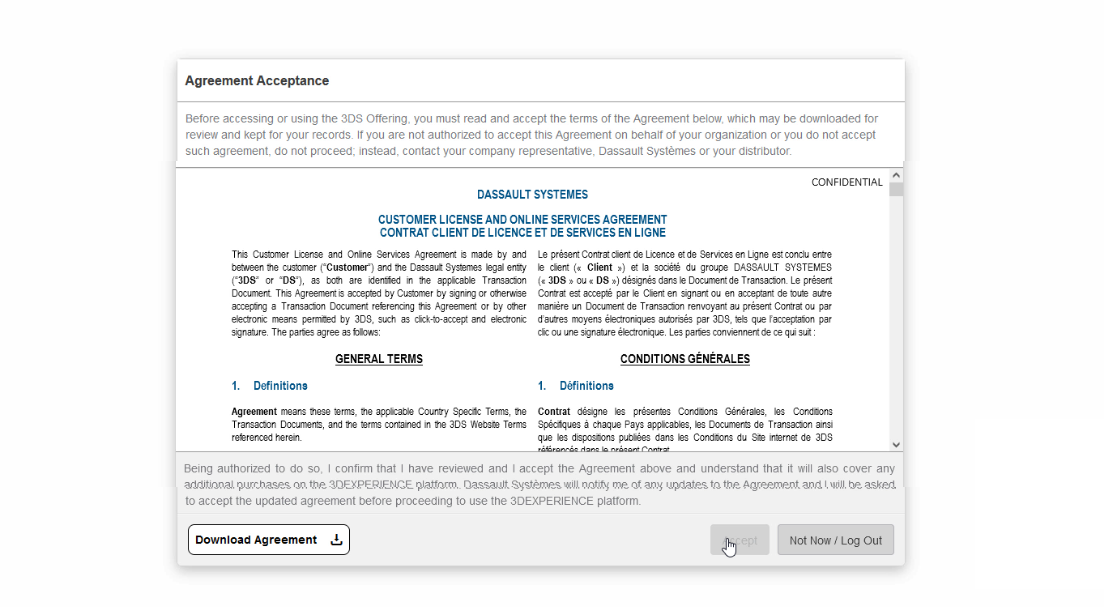

Shop Floor Programmer is a specialized role within the 3DEXPERIENCE platform designed to enhance CNC programming processes. It empowers concurrent engineering, allowing multiple teams—such as design, programming, and manufacturing—to collaborate in real time on a single platform.

By integrating seamlessly with SOLIDWORKS and other DELMIA roles, Shop Floor Programmer connects stakeholders across your entire organization, ensuring that changes in CAD designs are instantly reflected in NC programs. This integration eliminates the need for redundant workflows, accelerates time-to-market, and protects intellectual property through centralized data management.

For manufacturers looking to optimize their product development and machining processes, Shop Floor Programmer delivers a streamlined and scalable approach to modern CNC programming.

How Does NC Shop Floor Programmer Simplify Setup?

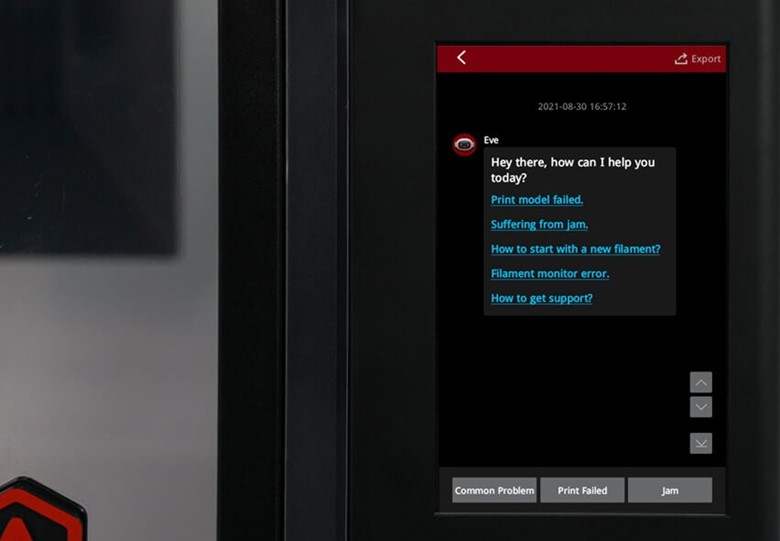

Setting up CNC operations has traditionally been a complex and time-intensive process. Shop Floor Programmer simplifies this with its intuitive graphic dialog boxes and machining operation definition panel, which guide you through the setup process step-by-step. By presenting options in a user-friendly interface, the tool eliminates guesswork, reduces errors, and ensures that even less experienced users can achieve optimal results.

One of its standout features is automatic feature recognition, which identifies machining features such as pockets, holes, and contours directly from the CAD model. This significantly reduces programming time and ensures precise machining, all while maintaining the highest levels of accuracy.

Additionally, the help icon provides immediate, contextual assistance making it easier to troubleshoot challenges or learn new workflows. This combination of user-friendly tools and on-demand support ensures that Shop Floor Programmer is accessible to users of varying skill levels while delivering the precision required in high-stakes manufacturing.

Optimizing Toolpaths with Machine Simulation

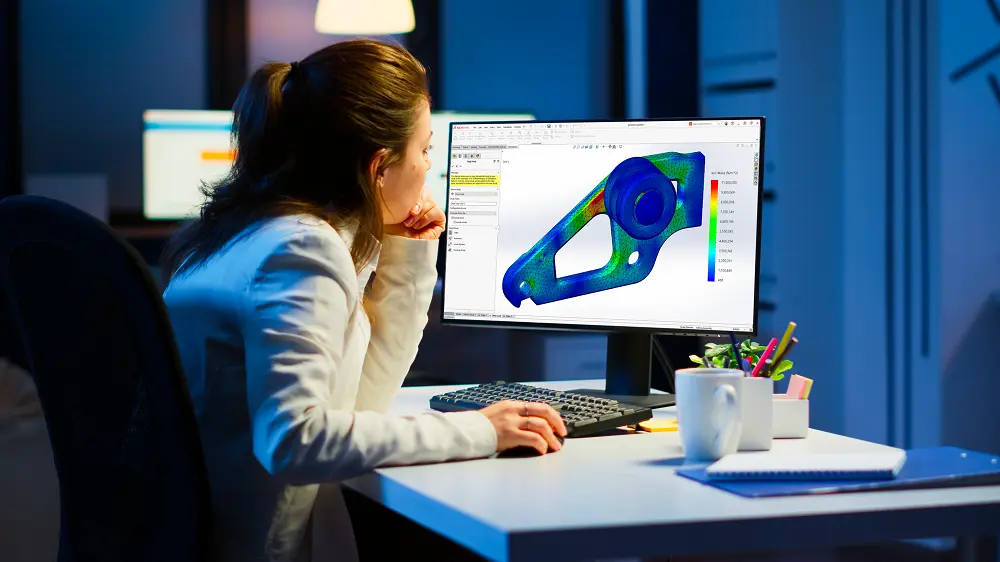

In CNC programming, ensuring that toolpaths are error-free before production is critical to avoiding costly mistakes and delays. Shop Floor Programmer leverages machine simulation to empower programmers to validate toolpaths in a realistic virtual workplace, replicating the exact conditions of the tool’s physical environment.

This feature provides a comprehensive visualization of machining operations, allowing you to check for potential collisions, unnecessary tool movements, or inefficiencies in the cutting process. For example, validating the behavior of a cutter tool assembly ensures that it interacts correctly with the workpiece setup and machine components. By addressing potential issues during the programming stage, your teams can dramatically reduce the likelihood of production delays caused by unforeseen complications.

Additionally, machine simulation supports NC accessories like fixtures and clamps, ensuring that all components are accounted for during toolpath validation. This results in a safer, more reliable manufacturing process that minimizes scrap and maximizes throughput. The ability to simulate various scenarios also empowers you to optimize cutting strategies, achieving a perfect balance of speed and precision.

Milling Operations

Milling is one of the most intricate operations in CNC machining, requiring precise control over machine movements and cutting strategies. Shop Floor Programmer excels in this domain, offering a suite of advanced tools designed to simplify and enhance milling operations.

Key features include precise control over machine rotations, which is essential for achieving high-quality finishes and maintaining tolerances in complex geometries. This level of control lets you handle intricate toolpaths with ease, ensuring that the final product meets your exact specifications.

The role’s seamless integration with NC machines ensures that programs are compatible with a wide variety of equipment, from basic 2.5-axis setups to advanced multi-axis milling centers. This flexibility allows teams to adapt Shop Floor Programmer to their specific production needs, making it an invaluable tool for both small shops and large-scale manufacturers.

Beyond programming capabilities, Shop Floor Programmer also supports efficient tool changes, reducing machine downtime and ensuring uninterrupted workflows. With its robust features and intuitive interface, the role lets you optimize every aspect of your milling process, from toolpath simulation to final production, improving productivity and reducing costs.

Benefits of Using a Single Platform

Working on a single platform like the 3DEXPERIENCE platform offers a host of benefits, including:

- Data management: Ensure intellectual property remains secure while providing real-time updates.

- Collaboration: Empower the entire organization to work together, from product development to machining.

- Scalability: The platform accommodates both small teams and large operations.

Best Practices

To fully leverage Shop Floor Programmer, follow these best practices:

- Use automatic feature recognition to save time during programming.

- Validate toolpath programs using machine simulation to reduce errors.

- Regularly update documentation to reflect design changes and adjustments to parameter settings.

How Does Toolpath Simulation Improve Accuracy?

Toolpath simulation enables teams to visualize machining operations in detail. By simulating the tool’s physical environment, users can address potential issues with NC machine operations before production, minimizing the risk of unexpected issues.

DELMIA Integration

NC Shop Floor Programmer integrates seamlessly with DELMIA applications, ensuring that ERP systems and machining teams are aligned. This integration supports better documentation, enhances the accuracy of tool assemblies, and ensures the smooth execution of NC programs.

CNC Machining

Whether you’re programming for CNC machines or managing cutter configurations, Shop Floor Programmer excels in creating efficient, error-free processes. Its features allow you to optimize setup time while improving the quality of your machining results.

Handling SOLIDWORKS Design Changes

One of the standout features of Shop Floor Programmer is its ability to adapt to design changes seamlessly. When updates occur in CAD models, the tool automatically adjusts toolpath programs, keeping processes aligned and error-free.

Documentation and Stakeholder Collaboration

Shop Floor Programmer simplifies documentation for machining teams. By centralizing information on the 3DEXPERIENCE platform, it ensures all stakeholders have access to up-to-date, actionable data, improving communication across the entire organization.

Final Thoughts: How to Optimize CNC Programming with NC Shop Floor Programmer

In an industry where precision, efficiency, and adaptability are paramount, NC Shop Floor Programmer on the 3DEXPERIENCE platform stands out as a transformative solution. By uniting powerful tools for machining, toolpath simulation, and milling within a single, integrated platform, it addresses the core challenges faced by manufacturers today.

Seamlessly connect NC programmers, designers, and stakeholders, fostering collaboration across your entire organization. This integration ensures that design changes are automatically reflected in machining operations, eliminating the risk of miscommunication and reducing production delays. Additionally, the tool’s advanced features, such as automatic feature recognition and realistic virtual workplace simulation, empower you to optimize your workflows and achieve error-free results.

Whether it’s simplifying workpiece setup, enhancing toolpath programs, or integrating with existing NC machines, the NC Shop Floor Programmer role on the 3DEXPERIENCE platform provides a comprehensive, scalable solution tailored to modern manufacturing needs. With this role, manufacturers can transform their approach to CNC programming, unlocking new levels of precision and efficiency.

Ready to take the first step toward optimized manufacturing?—Reach out and discover the power of NC Shop Floor Programmer on the 3DEXPERIENCE platform today!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: