In the world of modern manufacturing, where precision and efficiency reign supreme, the role of a Shop Floor Programmer has emerged as a crucial cog in the production machine. But what exactly does a Shop Floor Programmer do, and why is it so vital in today’s manufacturing landscape? In this article, we’ll demystify the Shop Floor Programmer role, both on the 3DEXPERIENCE platform and on the production floor, and shed light on why it’s an indispensable part of the quickly digitalizing modern manufacturing process.

The Shop Floor Programmer: A Key Player in CNC Machining

At its core, the Shop Floor Programmer is the mastermind behind the CNC (Computer Numerical Control) machines on the shop floor. These professionals are responsible for translating intricate design blueprints and concepts into a language that machines can understand and execute. In essence, they bridge the gap between design and reality, turning digital visions into tangible products.

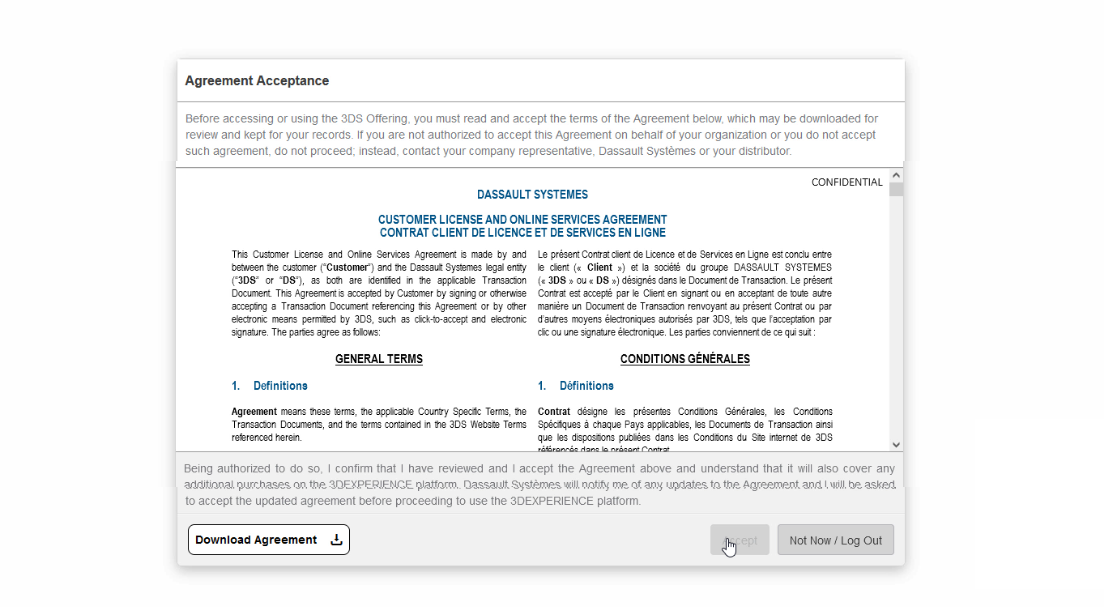

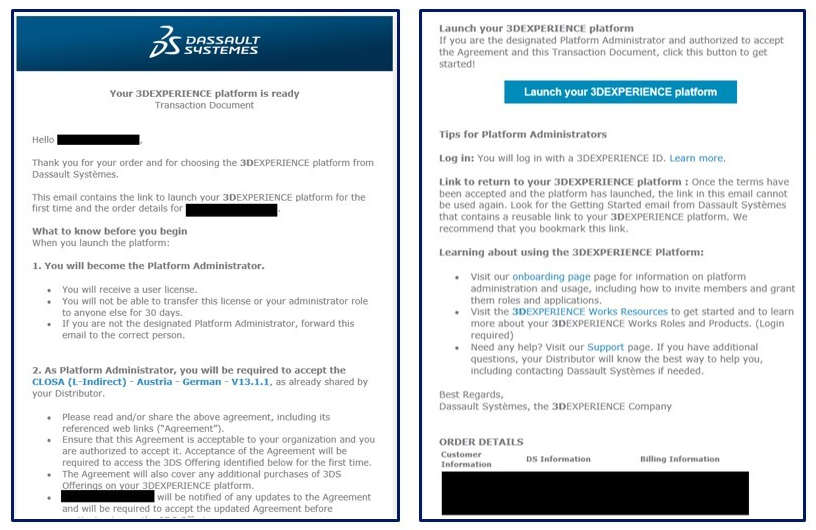

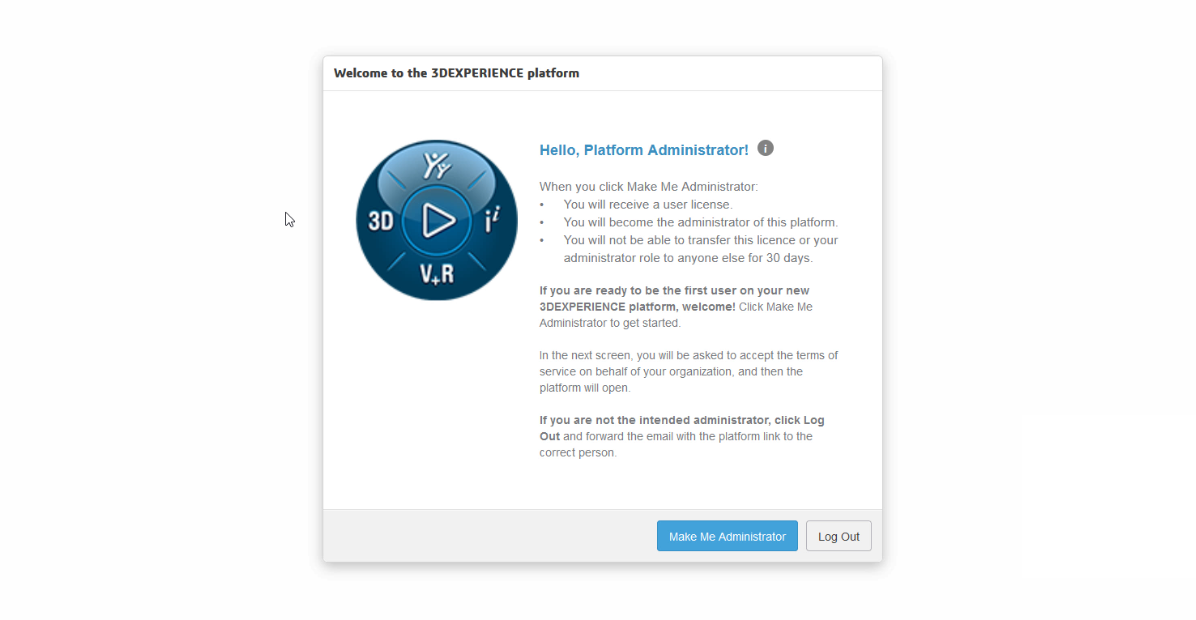

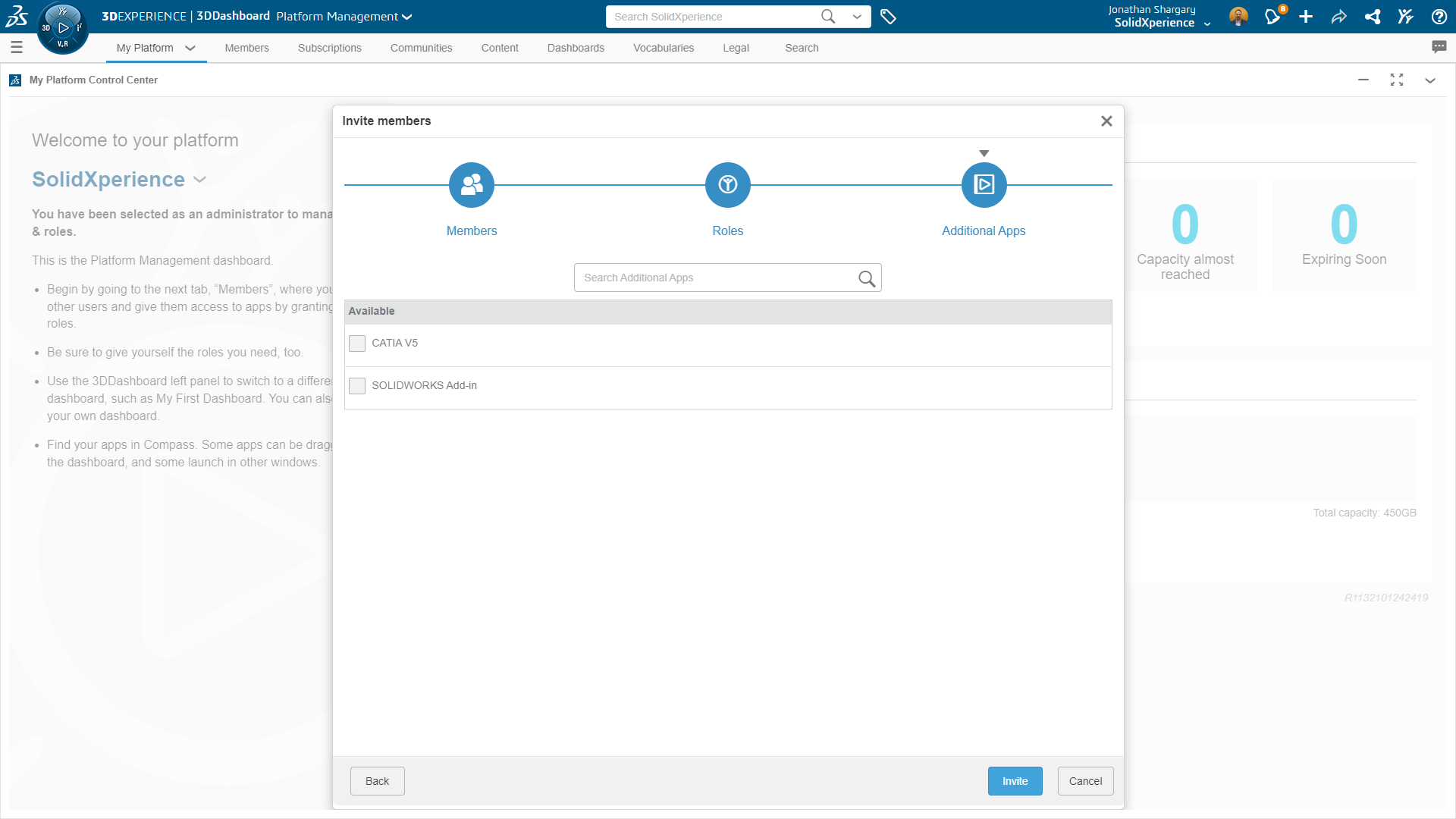

Structured Roles on the 3DEXPERIENCE platform

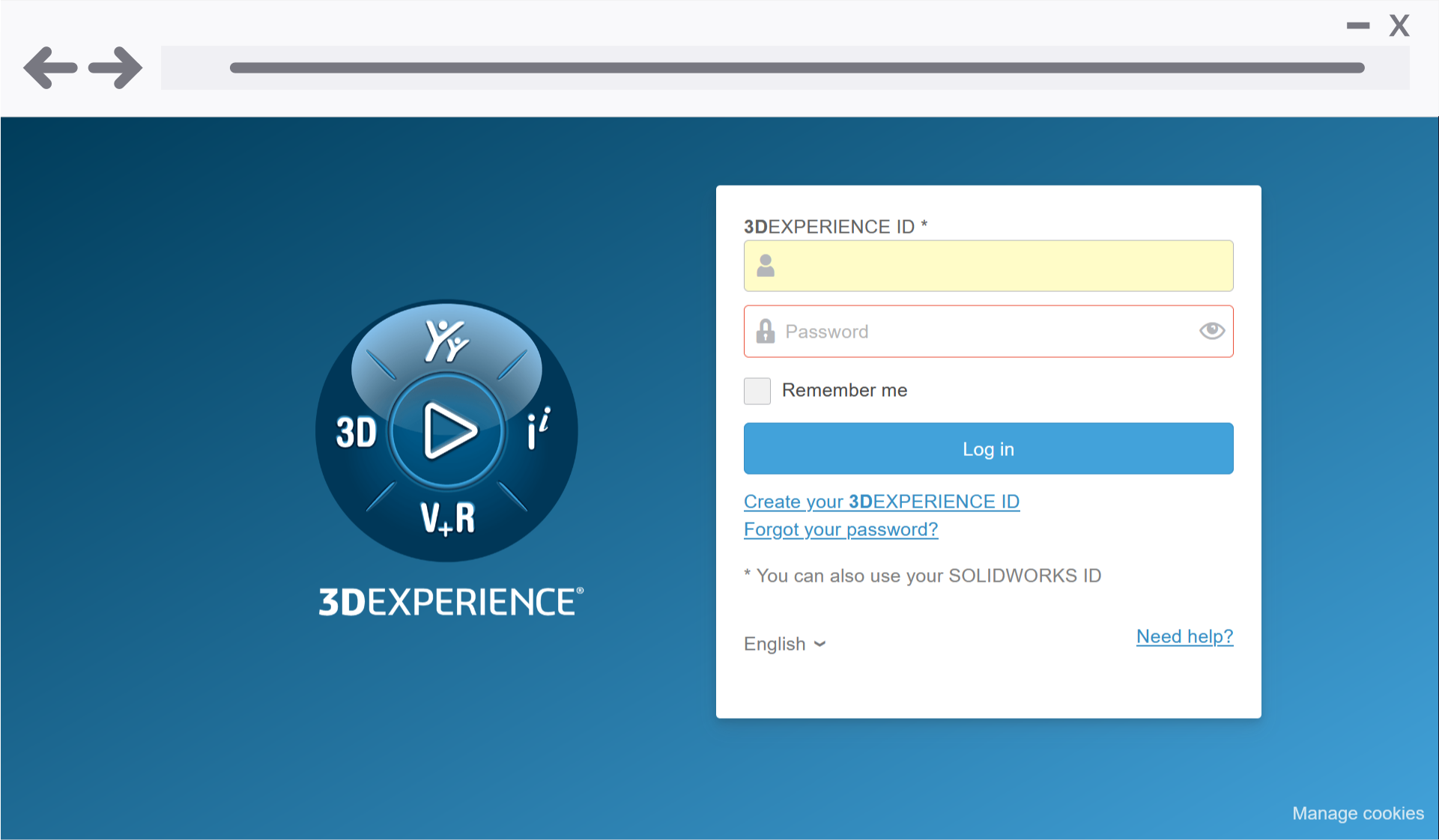

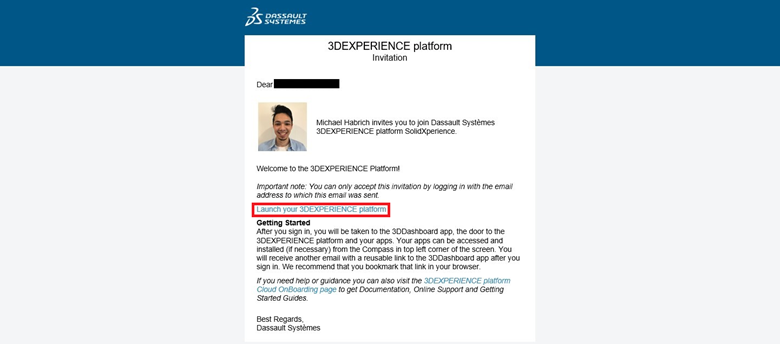

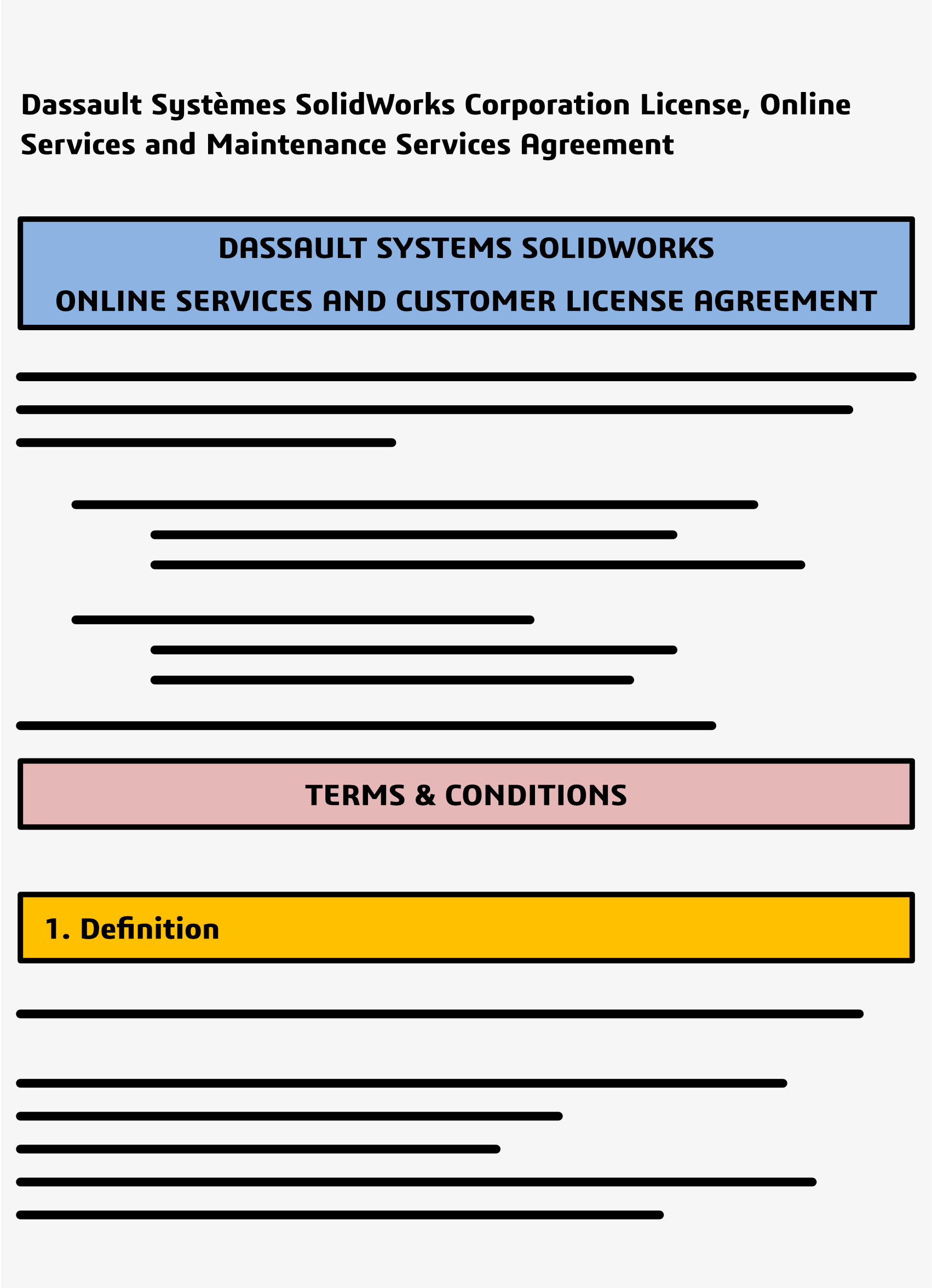

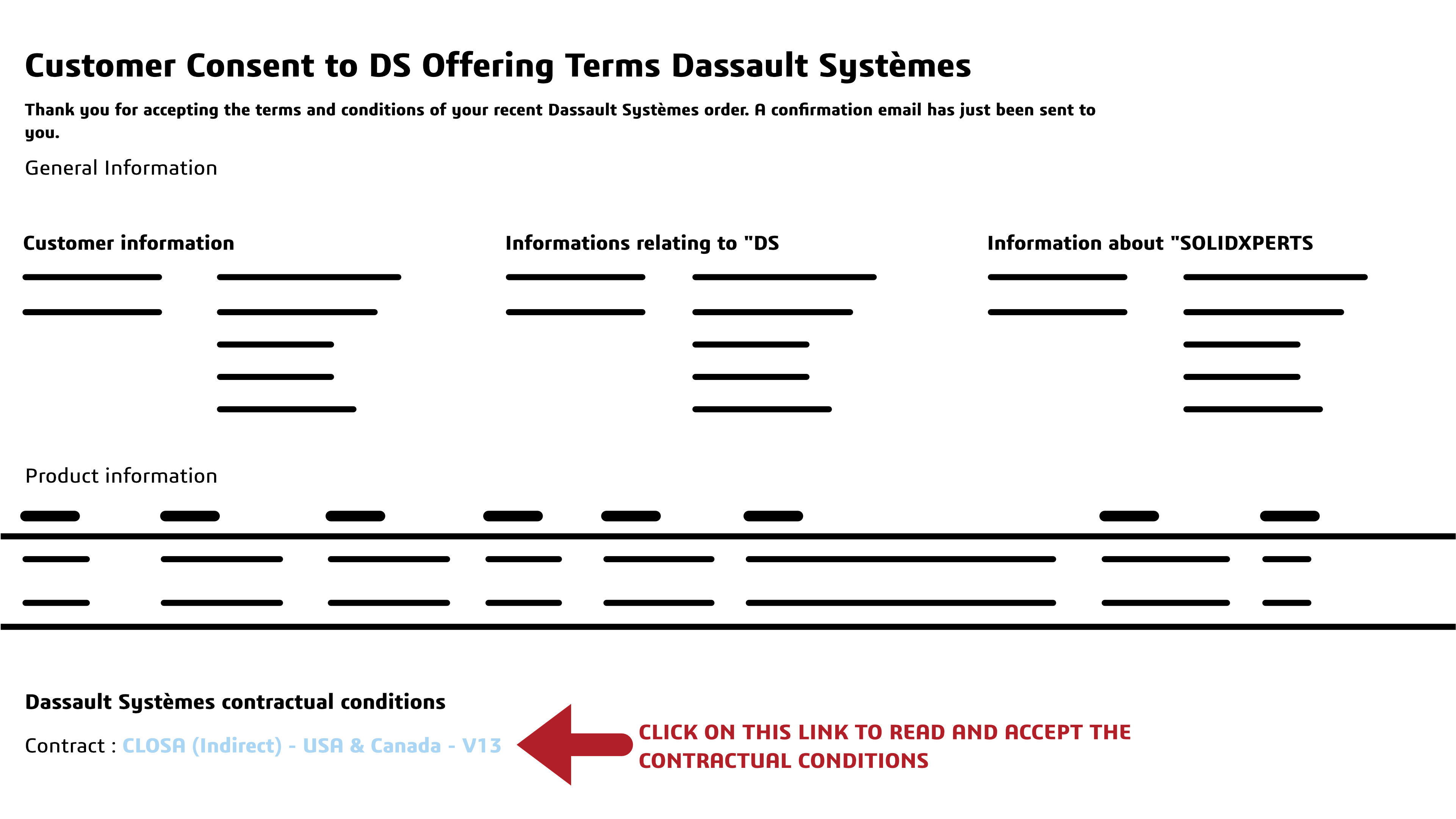

Roles on the 3DEXPERIENCE platform are meticulously designed to mirror vital positions within the industry, ensuring that users have access to the apps, tools, and capabilities on the platform they’ll need to excel in their position. The Shop Floor Programmer role is no exception, as it’s crafted to empower professionals in CNC machining and shop floor management with a comprehensive toolkit to meet the demands of manufacturing.

Equipping Shop Floor Programmers for Success

To excel in the Shop Floor Programmer role, on the 3DEXPERIENCE platform, and in the manufacturing industry at large, individuals need a combination of technical prowess and a deep understanding of the manufacturing process. Here are the essential tools and skills that empower them to thrive:

- CNC Programming Expertise: Proficiency in CNC programming is at the core of the role. This includes understanding the intricacies of toolpath generation, G-code programming, and machine kinematics.

- CAD Design Familiarity: A solid grasp of computer-aided design (CAD) is essential for maintaining CAD-associativity and ensuring that design changes seamlessly propagate to CNC programs.

- Simulation Proficiency: Mastery of simulation tools is crucial to validate CNC programs, detect potential issues, and optimize machining operations. This requires an eye for detail and a knack for problem-solving.

- Machining Process Knowledge: Shop Floor Programmers must be well-versed in various machining processes, tool assemblies, and CNC accessories to create efficient and collision-free programs.

- Adaptability: The modern manufacturing landscape is constantly evolving. Shop Floor Programmers must stay updated with the latest industry trends and technologies to adapt to changes effectively.

- 3DEXPERIENCE platform Mastery: Finally, expertise in navigating and utilizing the 3DEXPERIENCE platform’s features and capabilities is fundamental. This includes harnessing the CNC Programming Wizard, CAD-associative instant update, toolpath verification, and more.

By equipping themselves with these essential tools and skills, professionals can excel in the Shop Floor Programmer role, ensuring the seamless translation of design concepts into high-precision, real-world products. This structured approach not only empowers individuals but also elevates the entire manufacturing process, contributing to enhanced efficiency, reduced downtime, and ultimately, greater success in the industry.

How does the Shop Floor Programmer role on the 3DEXPERIENCE platform help?

The Shop Floor Programmer role on the 3DEXPERIENCE platform provides users with a comprehensive set of tools and features that significantly enhance their daily tasks and responsibilities in CNC machining and shop floor management.

- Streamlines CNC Programming: The role simplifies the creation of CNC programs by offering an intuitive programming wizard. This means that users, even those with limited programming experience, can efficiently generate CNC programs for a wide range of machining operations, reducing the time and effort required.

- Ensures CAD-Associativity: Users can maintain strong associativity between their CNC programs and the original CAD designs. This instant-update feature ensures that any design changes are automatically reflected in the CNC program, reducing the risk of errors, and ensuring that the manufacturing process remains synchronized with design updates.

- Facilitates Toolpath Verification: Shop Floor Programmers can quickly verify and fine-tune toolpaths using the platform’s toolpath verification and editing capabilities. This enables them to identify and rectify any issues before they lead to costly errors during actual machining, reducing downtime and material wastage.

- Enables Advanced Simulation: The role empowers users to visualize and simulate CNC programs in a virtual environment. This capability allows them to detect accessibility problems, tool collisions, or other potential issues before they occur on the shop floor. It’s like having a digital testing ground to ensure program safety.

- Supports Prismatic and Wire EDM Operations: Users can create CNC programs for both prismatic machining and Wire EDM operations, expanding their capabilities to handle a wide variety of manufacturing needs.

- Maximizes Machine Tool Utilization: Shop Floor Programmers can optimize CNC programs to reduce non-value-added motions, minimize machining cycle times, and prevent collisions with other in-process parts. This efficient programming helps maximize machine tool utilization, leading to increased productivity.

- Mitigates Production Risks: By considering the physical environment of the CNC machines, tool assemblies, and accessories, the Shop Floor Programmer role helps reduce the risk of unexpected issues and production delays. Users can create CNC programs that are tailored to the specific machine and tooling, ensuring a smoother production process.

- Leverages Intellectual Property: Users can define and store machining processes as templates, standardizing and automating repetitive tasks. This not only saves time but also ensures consistency in manufacturing, leveraging the company’s intellectual property and enhancing productivity.

- Facilitates Rapid Response to Changes: With native associativity between machining programs and engineering/manufacturing data, users can quickly adapt to design changes or variations. This ability to respond effectively to engineering or manufacturing changes ensures a smoother transition from design to production.

In essence, the Shop Floor Programmer role on the 3DEXPERIENCE platform equips users with the tools and capabilities needed to streamline CNC programming, reduce errors, optimize machining processes, and mitigate production risks. It empowers them to excel in their daily jobs by making CNC programming more efficient, precise, and adaptable to the demands of modern manufacturing.

Why the Shop Floor Programmer Matters

The Shop Floor Programmer plays a pivotal role in ensuring that the manufacturing process runs smoothly and efficiently. By creating efficient NC programs and validating them through simulation, Shop Floor Programmers help minimize downtime due to errors or unexpected issues during production. They employ strategies to optimize toolpaths, reduce non-value-added motion, and avoid collisions, ultimately reducing the machining cycle time and maximizing machine tool utilization.

Shop Floor Programmers consider the physical environment of the CNC machines, tool assemblies, and accessories, reducing the risk of unexpected problems that could lead to production delays. Storing and reusing machining processes as templates not only saves time but also ensures consistency in manufacturing, leveraging a company’s intellectual property for greater productivity. With strong associativity between machining programs and design data, the Shop Floor Programmer role enables concurrent engineering, shortening the design-to-manufacturing cycle and allowing rapid responses to changes.

In conclusion, the Shop Floor Programmer is not just a behind-the-scenes operator; they are the orchestrators of precision and efficiency on the manufacturing floor. Their ability to create, validate, and optimize CNC programs, while seamlessly integrating them with design data, is instrumental in meeting the demands of modern manufacturing. As technology continues to advance, the role of Shop Floor Programmers will only become more critical in ensuring that businesses stay competitive and deliver top-quality products to the market.