The journey from concept to product launch now-a-days is fraught with challenges, especially for startups and small businesses. With limited resources, tighter budgets, and the constant pressure to innovate, these companies often find themselves competing against industry giants with far greater financial and technological capabilities. However, thanks to advanced design and engineering tools like SOLIDWORKS, the playing field is becoming increasingly level. This powerful CAD (Computer-Aided Design) software is providing startups with the tools they need to innovate, iterate, and bring their products to market quickly and efficiently, effectively closing the gap between them and their larger competitors.

The Startup Challenge: Innovation on a Budget

Startups are known for their innovative ideas and the drive to disrupt established industries. However, turning a brilliant idea into a market-ready product requires more than just creativity—it demands precise engineering, detailed planning, and the ability to quickly adapt to feedback and changes in the market. Traditional methods of product development, which often involve expensive physical prototypes and time-consuming revisions, can be prohibitively costly for startups.

This is where SOLIDWORKS comes into play. As a comprehensive suite of design, simulation, and manufacturing tools, SOLIDWORKS enables startups to virtually prototype their products, test various design iterations, and identify potential issues before they become costly problems. This digital-first approach not only saves time and money but also allows startups to iterate quickly, which is crucial in today’s rapidly changing market.

Virtual Prototyping: Speeding Up the Iteration Process

One of the most significant advantages of using SOLIDWORKS is the ability to create and test virtual prototypes. Unlike physical prototypes, which can be expensive and time-consuming to produce, virtual prototypes allow startups to explore multiple design options quickly and at a fraction of the cost. With SOLIDWORKS, startups can create highly detailed 3D models of their products, complete with complex geometries, materials, and mechanical components.

Once a model is created, SOLIDWORKS offers a suite of simulation tools that can analyze the design’s performance under real-world conditions. For example, startups can test how a product will react to stress, heat, or fluid flow, enabling them to identify potential weaknesses or points of failure before any physical prototype is built. This level of analysis is particularly valuable for startups that operate in highly regulated industries, such as medical devices or aerospace, where product failure can have severe consequences.

Moreover, SOLIDWORKS’ parametric design capabilities allow for easy modifications and iterations. If a design needs to be changed, whether due to new insights from simulation results or feedback from potential customers, adjustments can be made quickly without starting from scratch. This ability to iterate rapidly is a game-changer for startups, allowing them to refine their designs continuously and bring a polished, well-tested product to market faster than ever before.

Collaboration and Communication: Bridging the Gap Between Teams

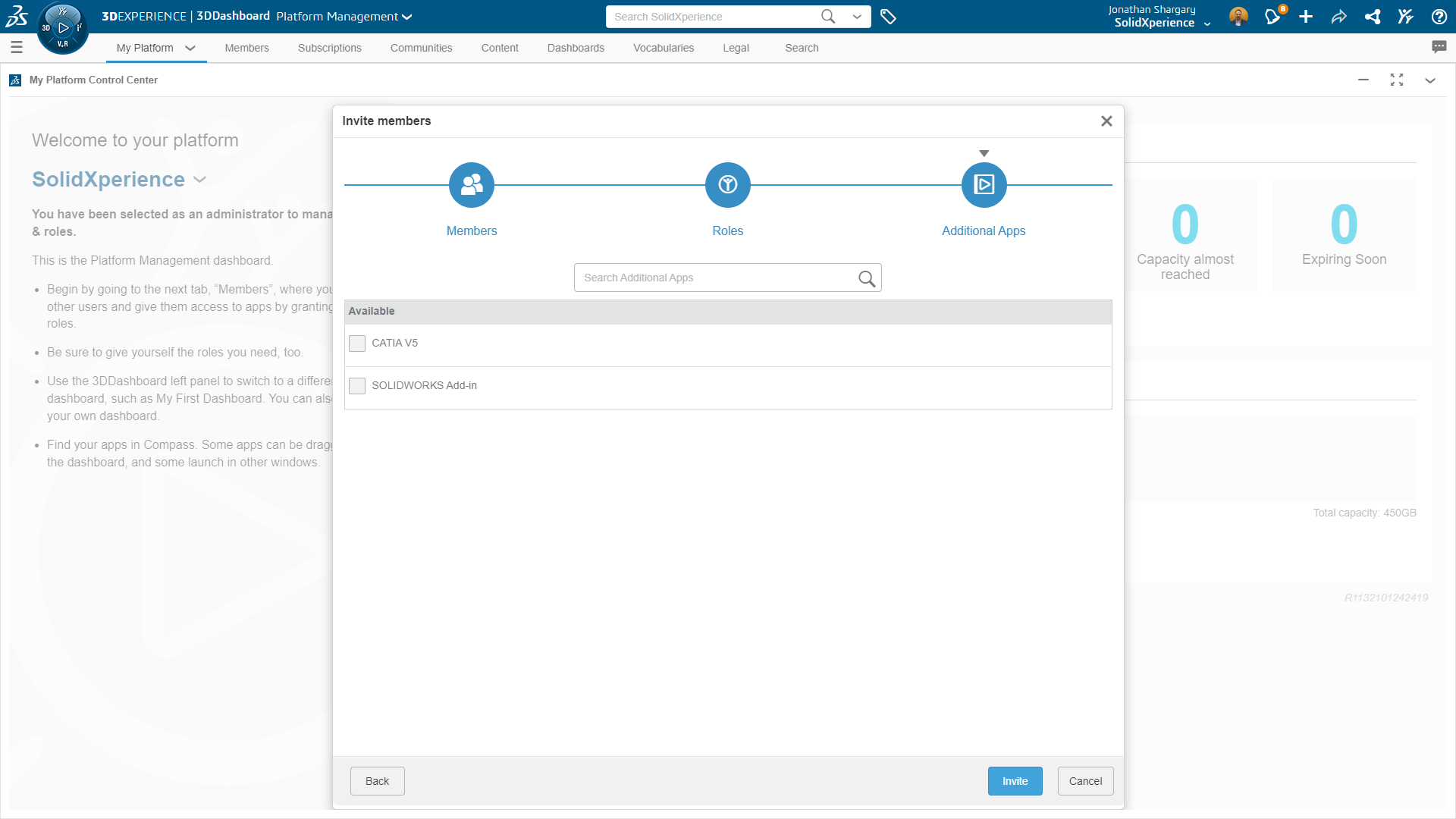

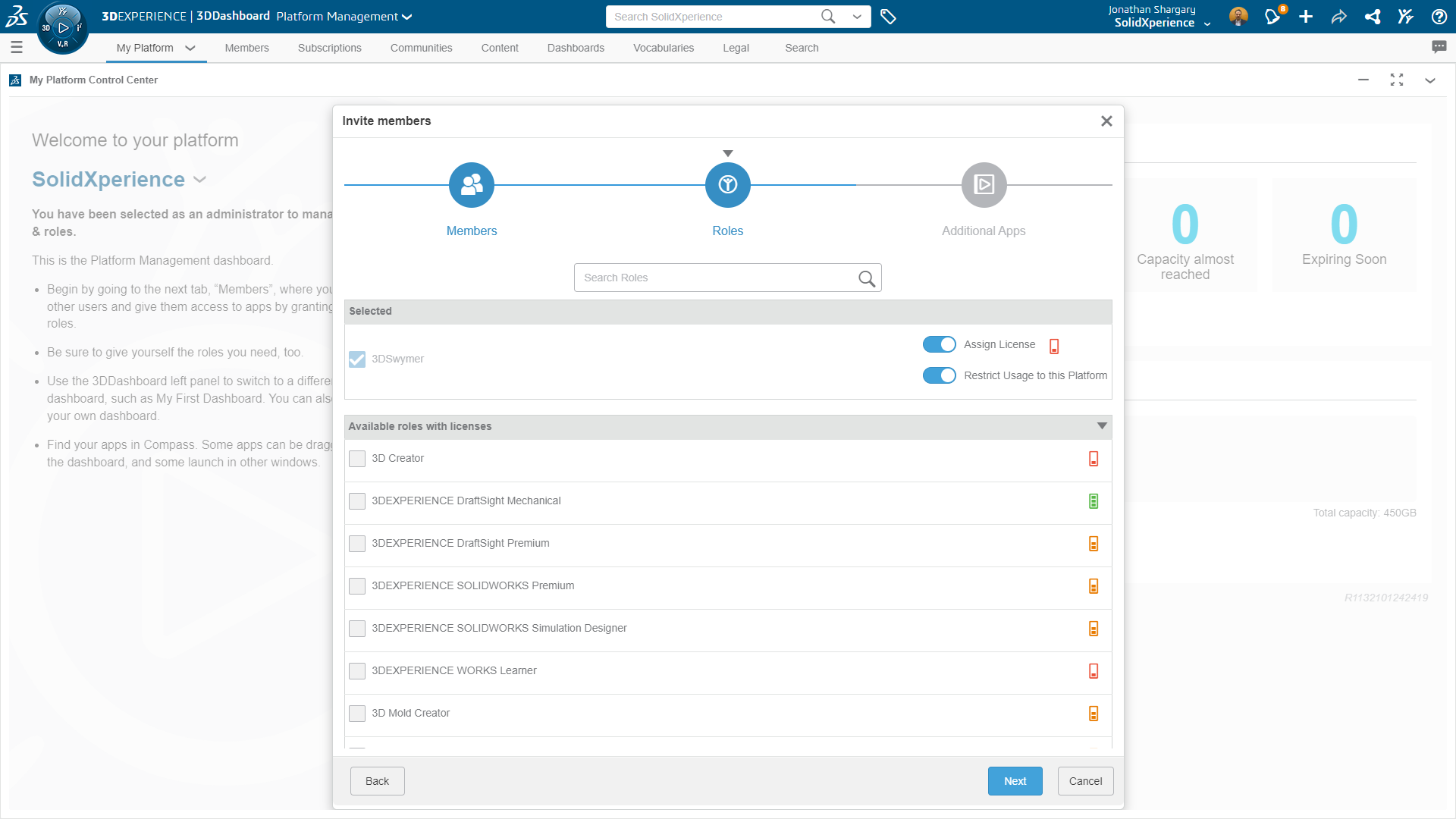

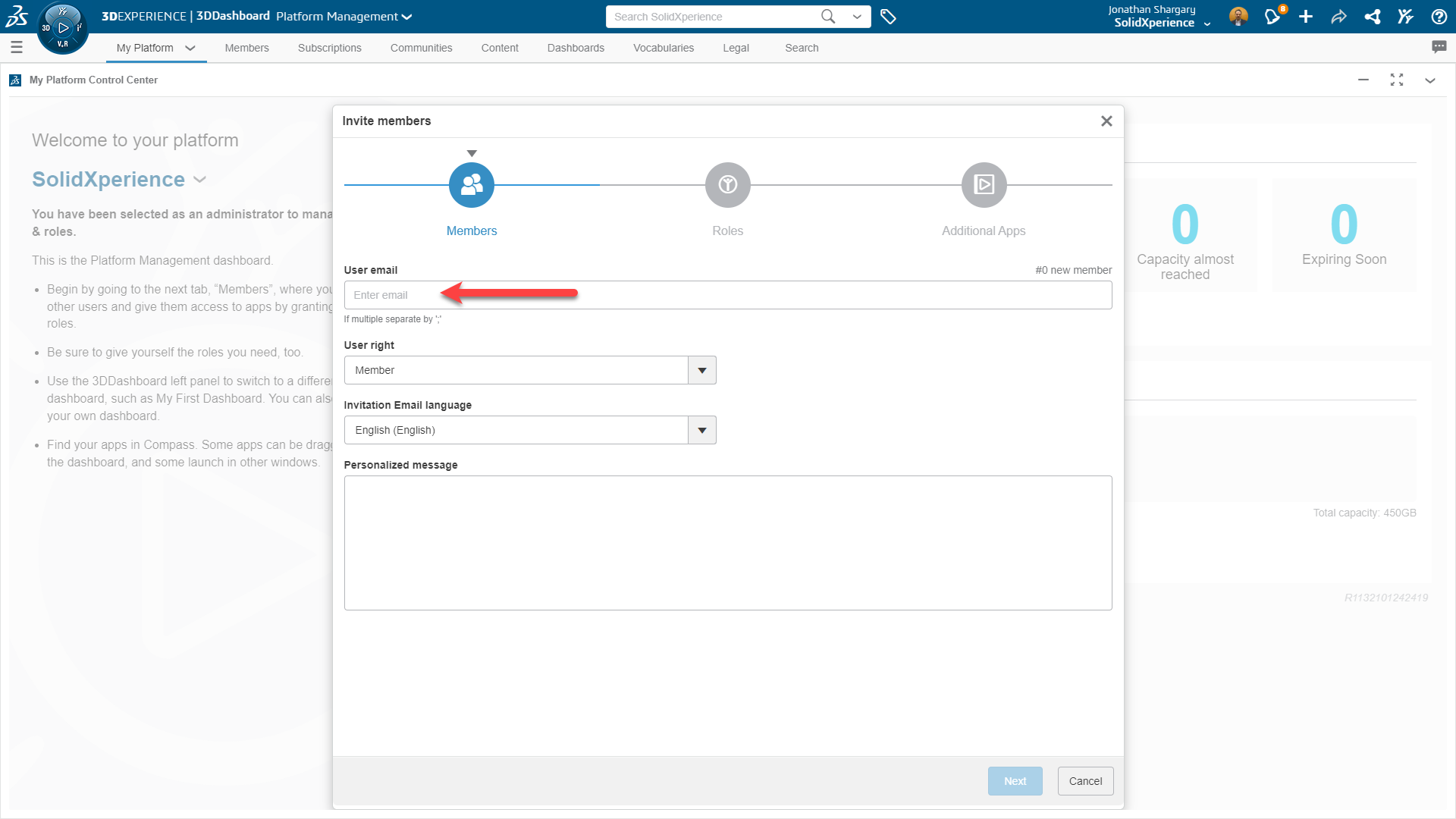

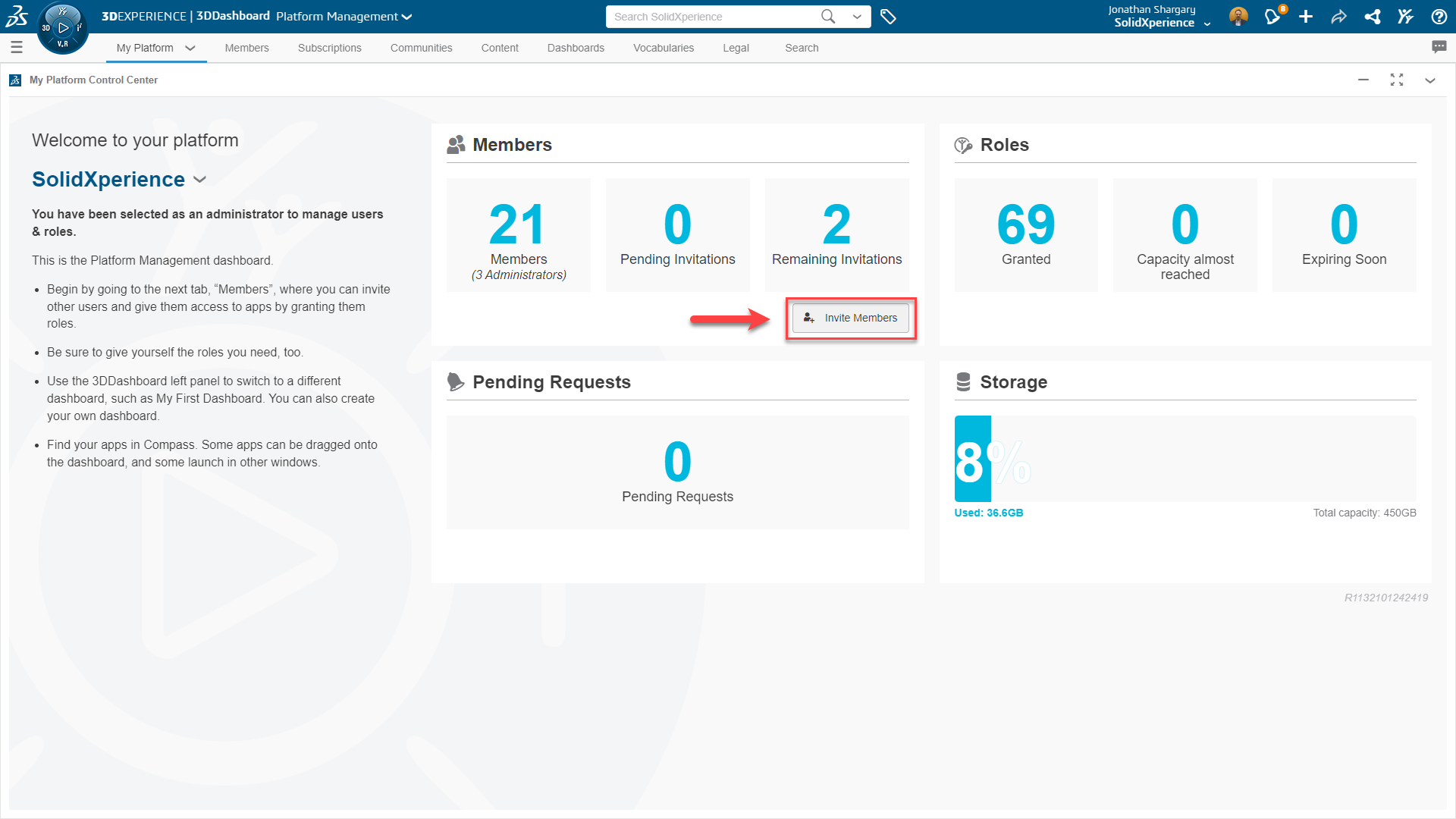

Another challenge that startups often face is effective collaboration and communication, especially as teams become more distributed and projects involve multiple stakeholders, including engineers, designers, investors, and manufacturers. SOLIDWORKS addresses this challenge by providing a unified platform where all team members can access the latest design data, share insights, and collaborate in real time.

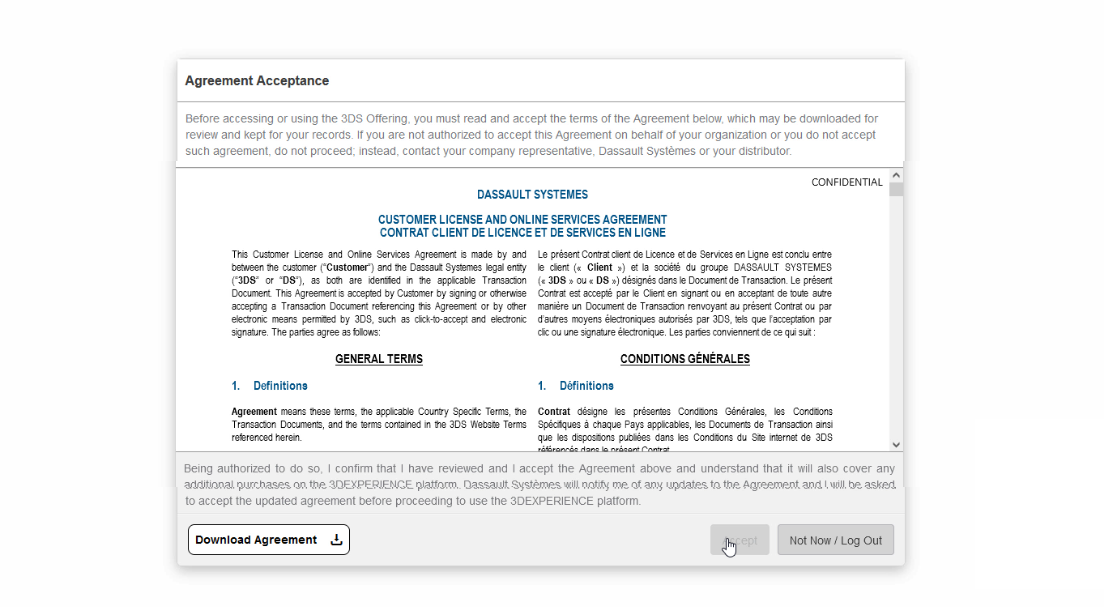

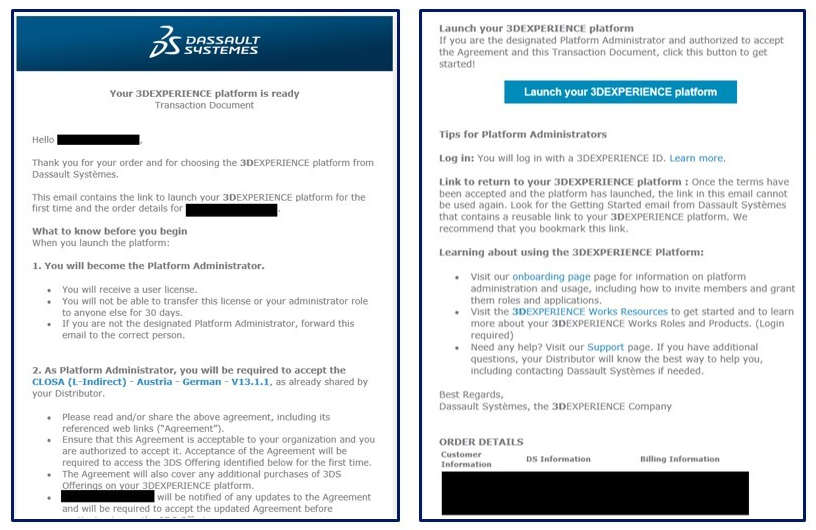

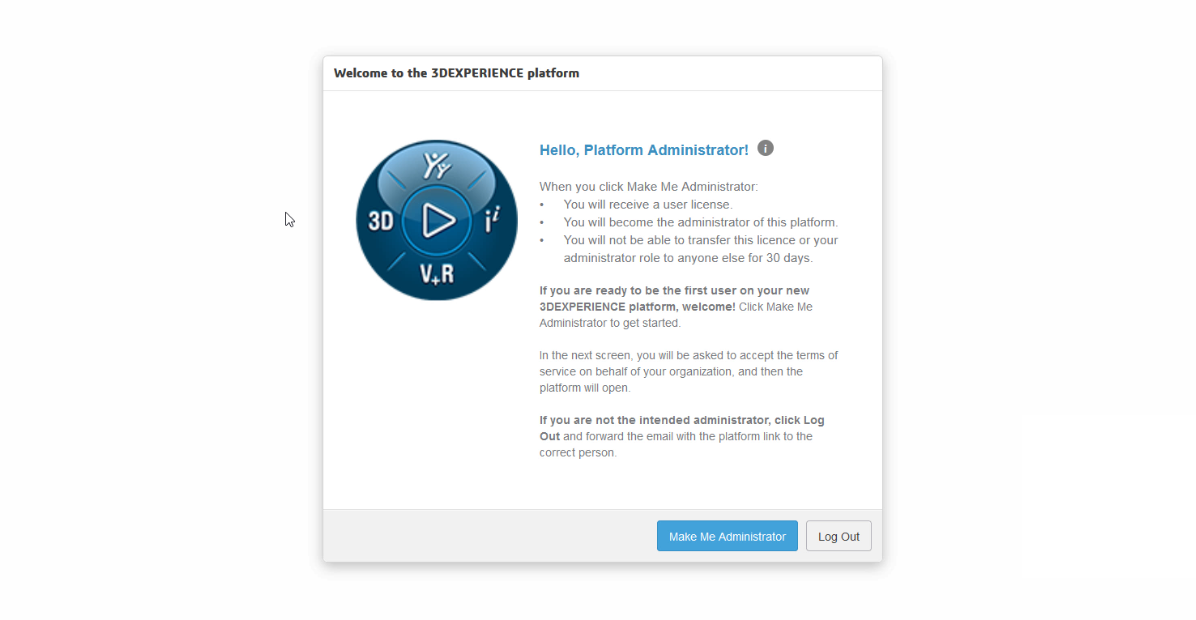

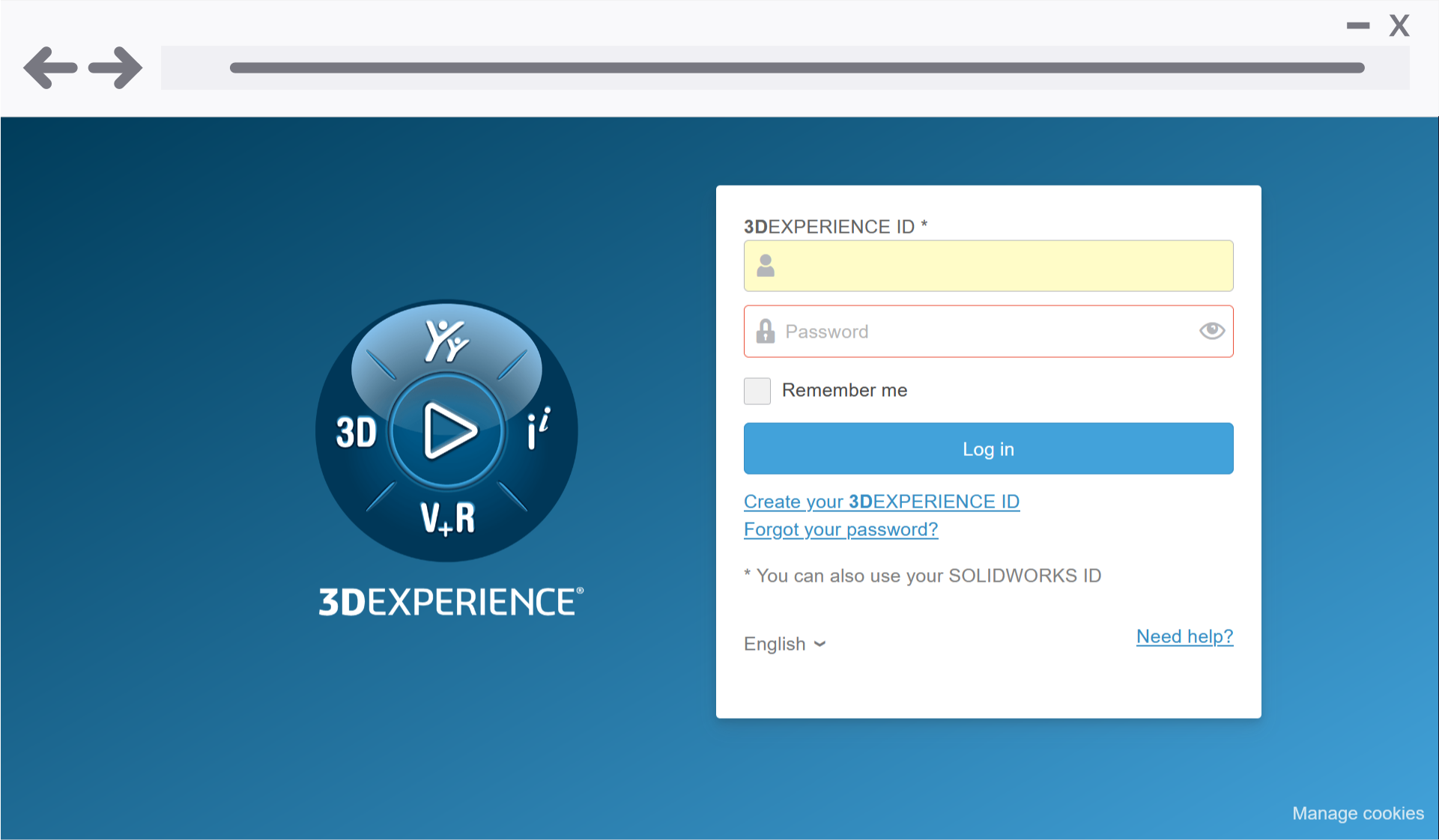

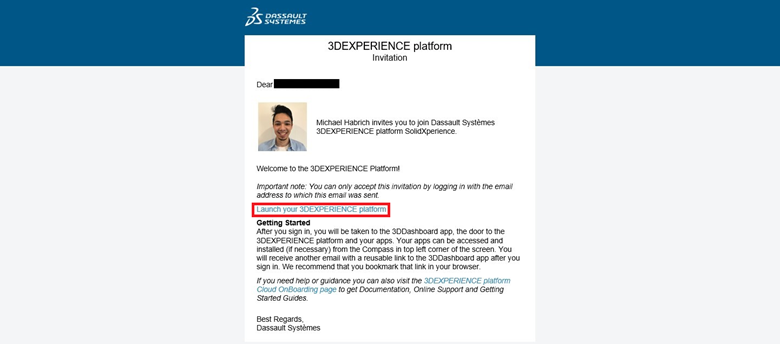

The 3DEXPERIENCE platform takes this a step further by integrating cloud-based tools for project management, collaboration, and data sharing. Startups can manage their entire product development process from a single platform, ensuring that everyone involved is on the same page. This not only streamlines communication but also reduces the risk of errors and miscommunication, which can be costly for startups operating on tight budgets.

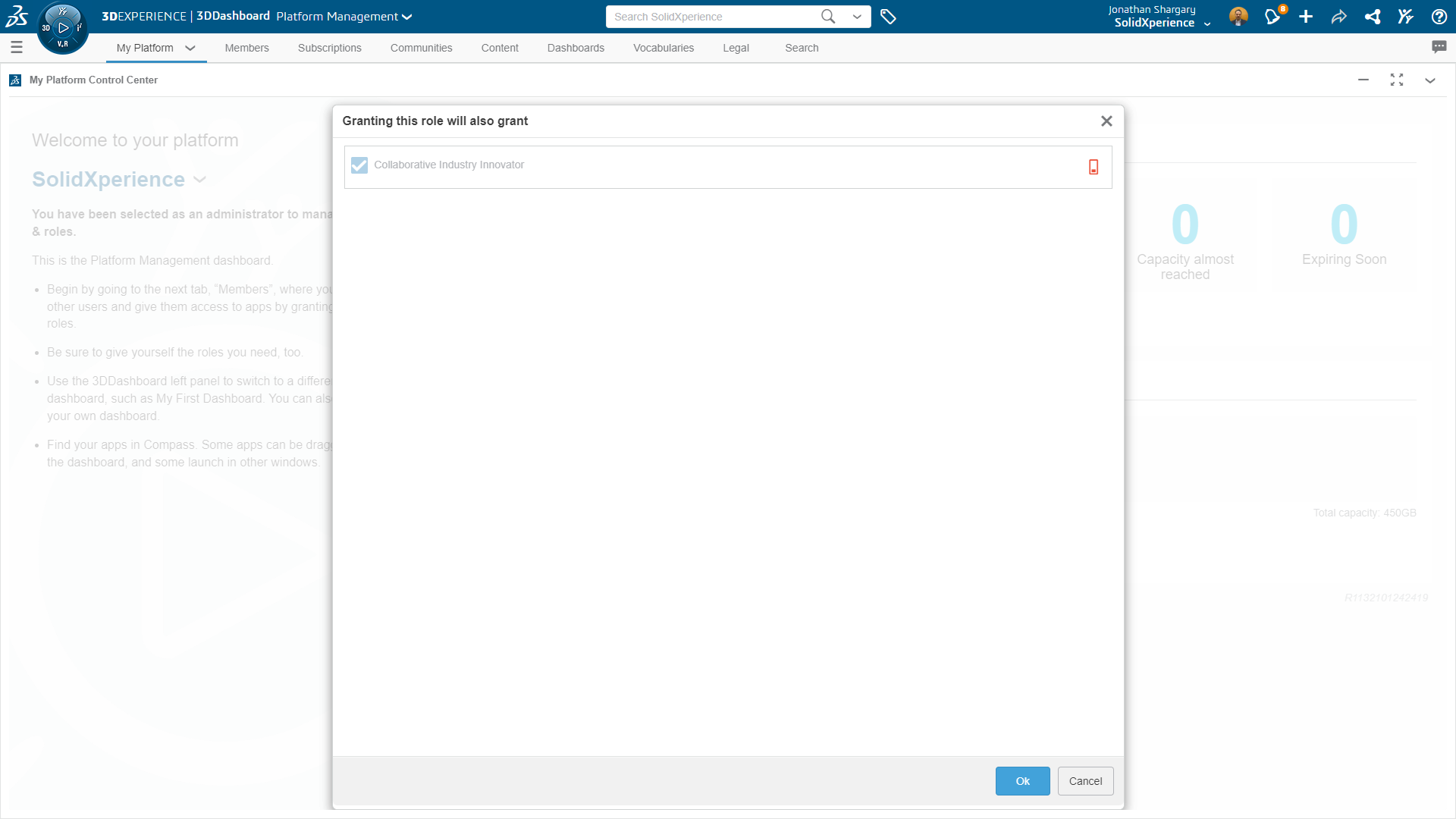

For startups working with external partners, such as contract manufacturers or suppliers, SOLIDWORKS also offers tools for secure data sharing. Startups can share 3D models, drawings, and other design data with their partners while controlling who has access to what information. This level of control is particularly important for startups that need to protect their intellectual property while still collaborating effectively with external stakeholders.

Cost-Effective Access to High-End Tools

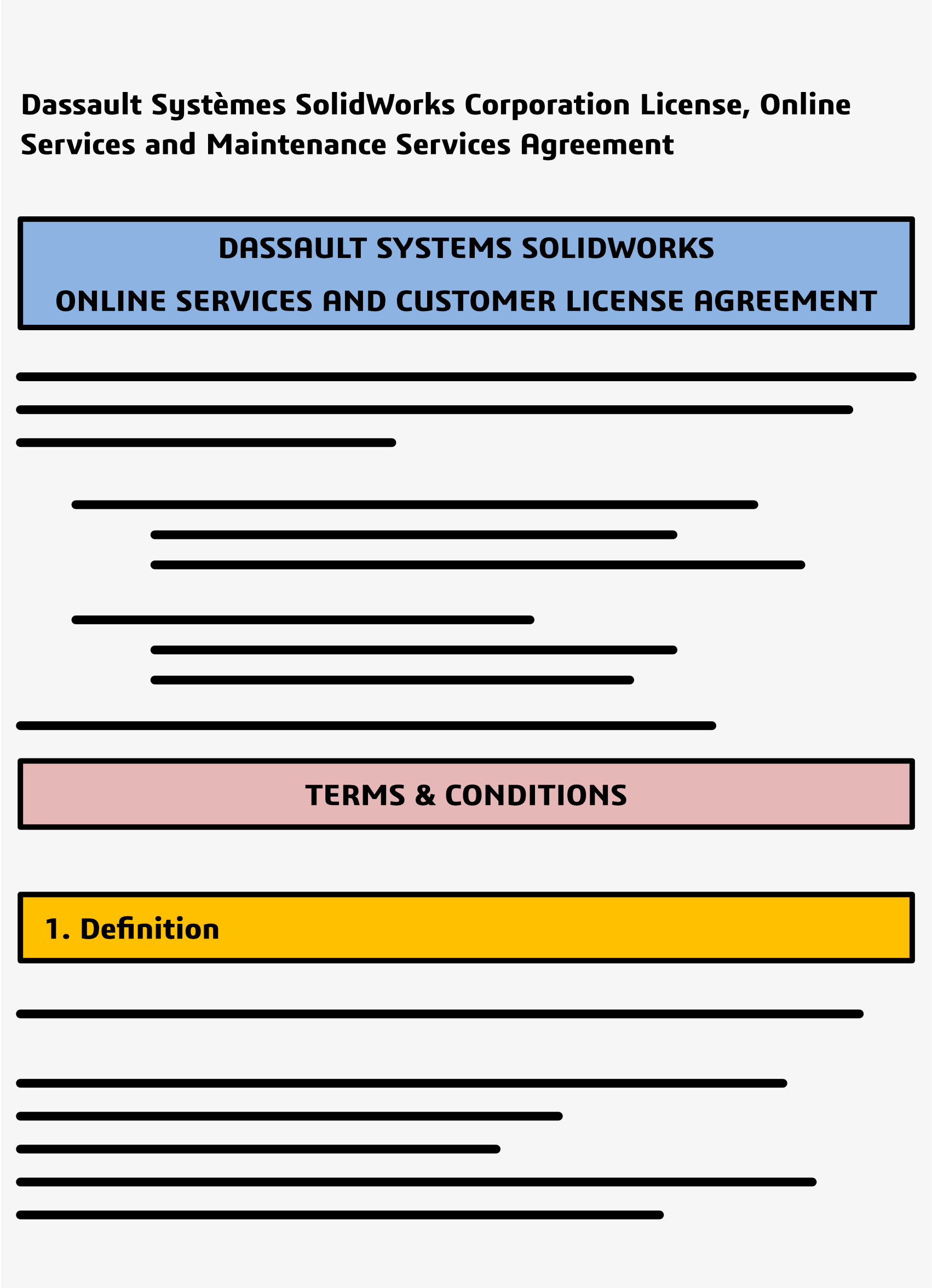

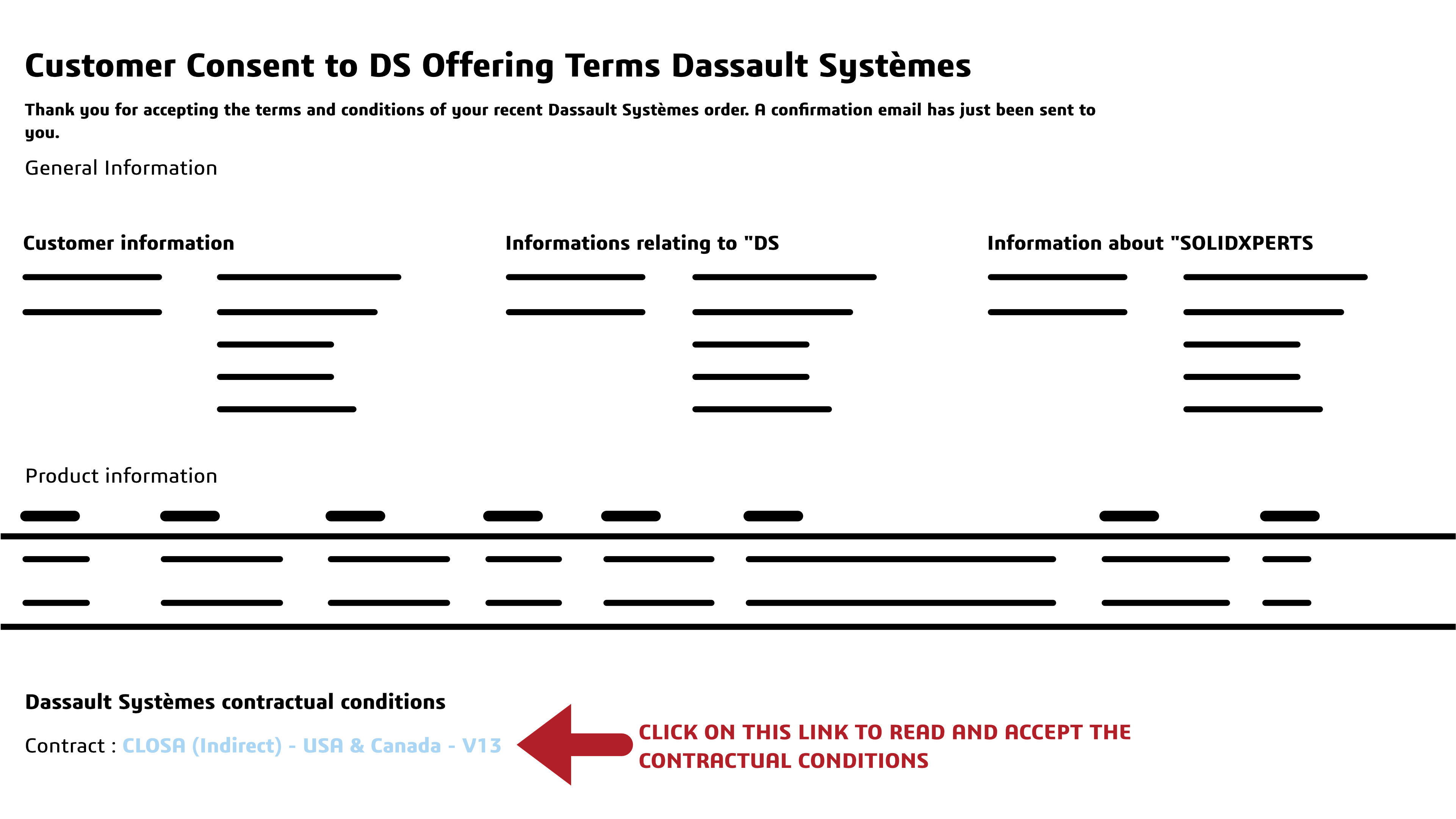

Historically, access to high-end CAD tools like SOLIDWORKS was limited to large companies with significant financial resources. However, in recent years, Dassault Systèmes, the company behind SOLIDWORKS, has made significant efforts to make the software more accessible to startups and small businesses.

One of the ways they’ve done this is through the SOLIDWORKS for Startups program, which offers startups access to the full suite of SOLIDWORKS tools at a significantly reduced cost. This program is designed specifically for early-stage companies that are working on innovative products but may not have the budget to invest in expensive software licenses. By providing affordable access to industry-leading tools, SOLIDWORKS is empowering startups to compete on equal footing with larger, more established companies.

In addition to affordable software licenses, SOLIDWORKS for Entrepreneurs also offers startups access to a global network of partners, mentors, and resources. This includes everything from technical support and training to marketing assistance and networking opportunities. For startups that are just starting, having access to this kind of support can be invaluable in navigating the complexities of product development and bringing a new product to market.

Real-World Success Stories

The impact of SOLIDWORKS on startups can be seen in countless success stories from around the world. One such example is Inmotive, a Canadian startup that developed an innovative two-speed transmission for electric vehicles. Using SOLIDWORKS, Inmotive was able to rapidly prototype and test their design, ultimately bringing their product to market faster and more efficiently than would have been possible using traditional methods.

Another example is Square Robot, a robotics startup that specializes in developing autonomous robots for inspecting oil storage tanks. Using SOLIDWORKS, Square Robot was able to develop and refine their robot’s design efficiently. The software’s advanced simulation tools allowed them to test various design iterations virtually, ensuring that the robot could withstand the harsh conditions inside oil storage tanks.

A Game-Changer for Startups

In a world where innovation is key to survival, startups need every advantage they can get. SOLIDWORKS is providing these companies with the tools they need to design, test, and bring their products to market quickly and efficiently, leveling the playing field between them and their larger competitors. By offering affordable access to high-end tools, streamlining collaboration, and enabling rapid iteration through virtual prototyping, SOLIDWORKS is empowering startups to turn their ideas into reality—and to do so with the confidence that they can compete with even the largest players in their industry.

As the startup ecosystem continues to grow, and as more and more companies look to disrupt established industries with innovative products, SOLIDWORKS will undoubtedly remain at the forefront of this movement, helping to drive the next generation of entrepreneurs toward success.