Introduction

Robot(ics)-as-a-Service, or RaaS for short, is an emerging business model that works kind of like how you subscribe to apps or online services, but for robots. This innovative approach offers robotic automation solutions on a subscription basis, allowing companies to harness the power of advanced robotics without the hefty upfront investment. For small and medium-sized enterprises (SMEs), RaaS presents an exciting opportunity to stay competitive and agile in a dynamic market.

Industries that make stuff, sell stuff, or help keep us healthy are jumping on this trend to better automate tasks while keeping costs down.

What is Robot-as-a-Service (RaaS)?

RaaS provides businesses with access to robotic systems through a subscription model. It mixes old-school robotics with new tech like AI, machine learning, and cloud computing to make it easier and cheaper for businesses of all sizes to get into automation.

Instead of purchasing and maintaining robots, companies can rent them, paying regular fees that cover the cost of the machines, maintenance, software updates, and support services.

This approach offers scalability, reduced risk, and access to the latest robotic technologies, making automation more accessible and cost-effective.

The Growing Importance of RaaS in Business Automation

RaaS offers a cost-effective, scalable solution for businesses to improve efficiency and agility in a dynamic market. Thanks to its inherent flexibility and growth potential, it allows businesses to optimize their operations without high upfront costs, using a subscription or usage-based model.

Also, RaaS adapts to changing market conditions, enabling quick adjustments in robotic resources and maintaining predictable costs. Providers handle maintenance, upgrades, and support, ensuring the latest technology is always in use.

Exploring the Benefits of RaaS for Businesses

RaaS makes it easier and more cost-effective for businesses to leverage advanced robots. Businesses can boost productivity and flexibly adapt how they operate to keep up with highly competitive markets.

Cost Efficiency and Scalability

By adopting a RaaS model, organizations find it simpler to make their processes more efficient and bring in new automation ideas. Predictable costs make it easier for new businesses to start using this technology, and services can be tailored specifically to what each business needs.

Also, RaaS allows businesses to scale their robotic operations up or down based on their needs. This flexibility is particularly useful for industries with fluctuating demands, such as manufacturing, warehousing, and logistics.

Enhanced Productivity and Operational Flexibility

At the heart of the RaaS model, you’ll find a big boost in how much work gets done and how flexible operations can be. With RaaS on their side, companies can smooth out their processes, become more efficient, and quickly adjust when their customer wants and needs change.

Impact of RaaS on Key Industries

Manufacturing

RaaS revolutionizes manufacturing by enabling SMEs to automate production lines, reducing labor costs and increasing efficiency. With flexible subscription models, companies can scale their robotic workforce based on demand, ensuring optimal productivity without significant capital expenditure.

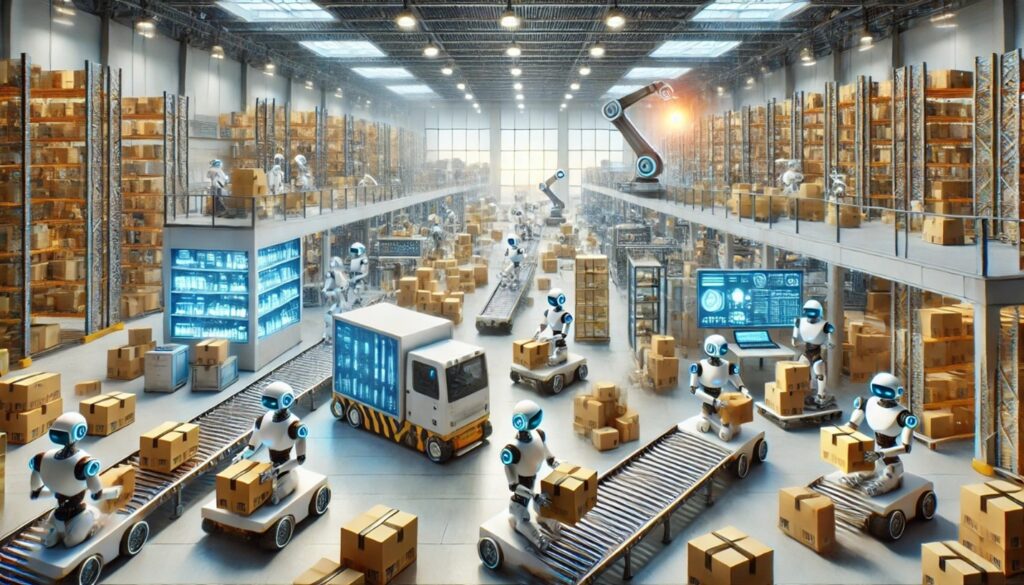

Warehousing and Logistics

In warehousing and logistics, RaaS can streamline operations by automating tasks such as sorting, packing, and transportation. This leads to faster order fulfillment, reduced errors, and improved inventory management, essential for maintaining a competitive edge in the fast-paced e-commerce sector.

Healthcare

RaaS can enhance healthcare delivery by providing robotic assistance in surgeries, rehabilitation, and patient care. These advanced robotic solutions can improve precision, reduce recovery times, and increase the overall quality of care, making them invaluable assets for healthcare providers.

Aerospace and Defense

In aerospace and defense, RaaS supports complex manufacturing processes and maintenance tasks. Robotic systems can handle intricate assembly operations, conduct inspections, and perform maintenance in hazardous environments, improving safety and efficiency.

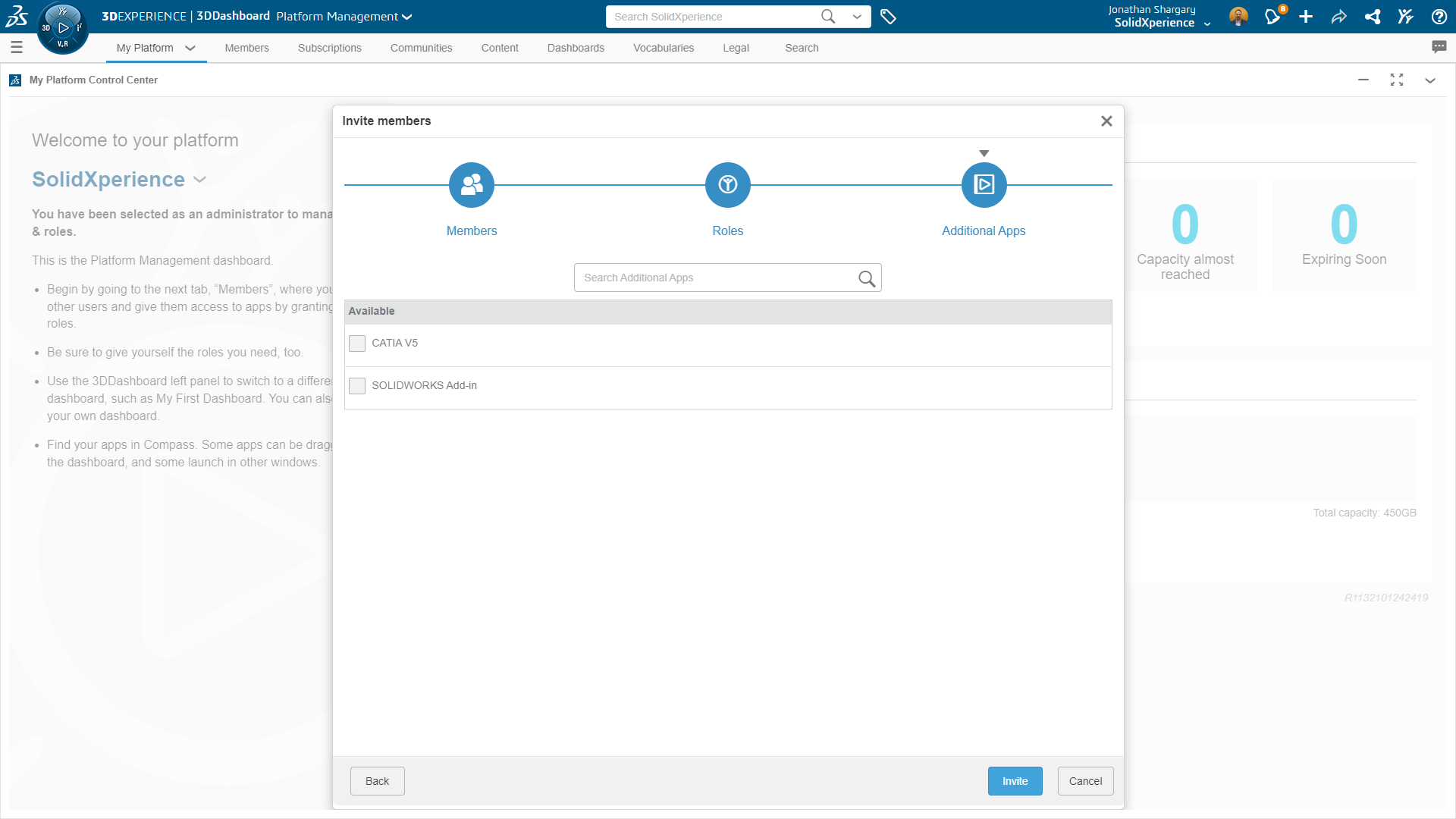

How SOLIDWORKS Supports RaaS Adoption for SMEs

The SOLIDWORKS portfolio offers a comprehensive suite of tools that can support SMEs in adopting an RaaS model:

- SOLIDWORKS 3D CAD: Essential for designing robotic components and systems, SOLIDWORKS 3D CAD allows for precise modeling and assembly, ensuring robust and efficient robotic solutions.

- SOLIDWORKS Simulation: This tool enables SMEs to test and validate robotic designs under real-world conditions, ensuring reliability and performance before deployment.

- SOLIDWORKS Electrical: By integrating electrical systems with mechanical designs, SOLIDWORKS Electrical ensures seamless functionality and reduces the complexity of robotic systems.

- SOLIDWORKS PDM (Product Data Management): Managing design data and documentation, SOLIDWORKS PDM ensures version control and collaboration, crucial for developing and maintaining robotic systems.

- SOLIDWORKS Manage: Providing advanced data management capabilities, SOLIDWORKS Manage helps SMEs oversee the lifecycle of robotic systems, from development to deployment and maintenance.

- SOLIDWORKS Composer: This tool aids in creating technical documentation, ensuring that RaaS clients have access to clear instructions for operating and maintaining robots.

- SOLIDWORKS Visualize: High-quality rendering and visualization capabilities of SOLIDWORKS Visualize help create compelling marketing materials and presentations, essential for promoting RaaS offerings.

Tips and Strategies for Successful RaaS Deployment

To make sure a RaaS setup works well, companies need to think about a few key things. First off, they should really look into what they specifically need and want to achieve, then pick a RaaS provider that has the right robots and tech for those needs.

It’s also crucial to get how the service model and pricing work with the chosen provider. This means looking at initial costs, ongoing fees for subscriptions, and any extra charges that might pop up.

On top of this, it’s important for businesses to train their employees so everyone knows how to use these robotic tools properly. And don’t forget about keeping in touch with your RaaS provider regularly; talking things through can help sort out any bumps along the way during setup or later on down the line.

By following these steps and using robotics within an appropriate service model, businesses can effectively use RaaS to achieve successful automation.

Conclusion

By leveraging the SOLIDWORKS software portfolio, SMEs can design, simulate, and manage robotic systems effectively, facilitating the adoption of the RaaS model. This not only democratizes access to cutting-edge robotic technology but also empowers SMEs to enhance their operational efficiency, reduce costs, and stay competitive in their respective industries.

Embracing RaaS with the support of SOLIDWORKS tools can unlock new levels of innovation and productivity, enabling SMEs to thrive in an increasingly automated world.

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

3D Creator Streamlines Your Design Workflow

3D Creator Streamlines Your Design Workflow

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene)

PETG (Polyethylene terephthalate glycol)

PETG (Polyethylene terephthalate glycol)

Onyx by Markforged: High Performance Carbon Fiber

Onyx by Markforged: High Performance Carbon Fiber