Maximizing the potential of your SOLIDWORKS CAD solutions starts with having the right partner by your side—someone who truly understands your unique design needs. That’s where we come in. Solidxperts optimization services aren’t just about technical fixes; they’re about finding solutions that work for you. We’ll help you streamline your engineering workflow, eliminate those frustrating traditional licensing hassles or SNL setup headaches, help you iron out your workflows, and boost your team’s collaboration capabilities with the latest tools and secure cloud solutions. No matter the size of your business or the complexity of your challenges, our tailored approach makes sure you get the most out of your 3D design solutions.

Let’s work together to transform your operations, drive innovation, and take your designs to the next level!

What Are Solidxperts Optimization Services?

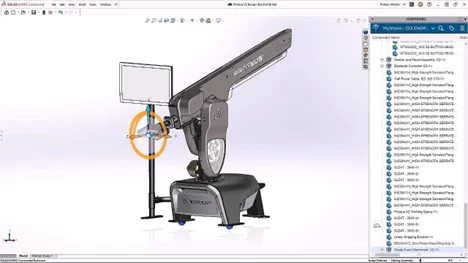

Solidxperts optimization services combine expert process and workflow consulting, streamlined IT administration, and cutting-edge tools like SOLIDWORKS CAD, PDM, and our full range of 3D printers to elevate your engineering workflow and product development cycle.

Your Optimization Partner

Our SOLIDWORKS certified specialists work directly within your company, conducting a thorough analysis of the working methods across each of your departments. Their detailed evaluation ensures that no aspect is overlooked, identifying opportunities for workflow streamlining, CAD technique improvements, and improved alignment between your processes and business objectives.

Once the evaluation is complete, you’ll receive a detailed Recommendations Report, providing actionable insights to help you maximize the value of your 3D modeling and additive manufacturing investments. With this roadmap in hand, you’ll gain clarity on how to implement cutting-edge methodologies designed to improve your ROI and enhance overall operational performance.

From improving product data management to providing new possibilities for design through additive manufacturing, experience streamlined engineering workflow and take your operations to the next level.

What Makes Solidxperts Optimization Services a Convenient Option?

Solidxperts provides a convenient option for businesses looking to avoid upfront complications and secure extra seats for growing teams. By eliminating the chaotic urgency often associated with implementing new tools and maximizing ROIs, we guarantee a smooth transition with minimal disruption to your workflows.

How Does Solidxperts Support Businesses Across Canada and Beyond?

With its main office in Montreal, Canada, and additional teams in Markham, Ontario, and Nashua, NH (USA), Solidxperts serves clients throughout North America. Whether you need help with network licenses, cloud services, or advanced 3D printing solutions, our team ensures a seamless design experience through personalized support and localized expertise.

Welcome to a New Dimension of Design

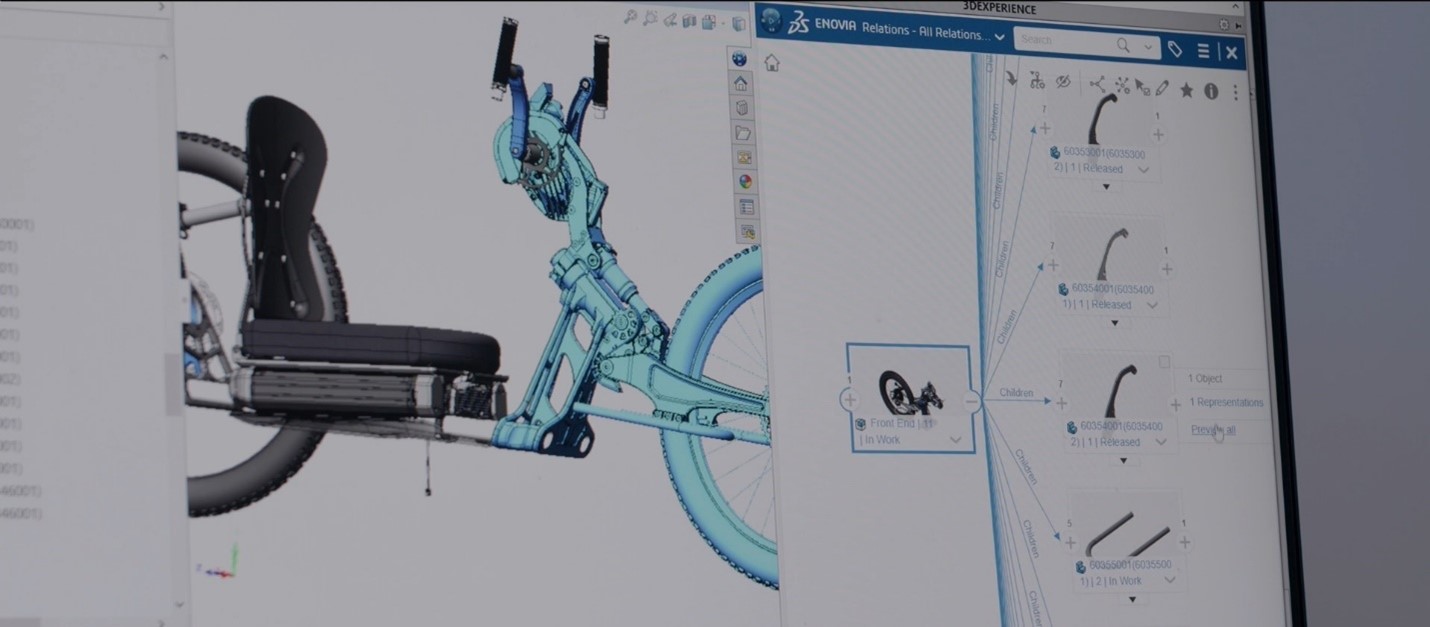

With the power of SOLIDWORKS CAD alongside our full suite of additive manufacturing solutions, you can revolutionize your entire design-to-manufacturing workflow. Imagine having the tools to move effortlessly from concept to production, reducing bottlenecks and enhancing efficiency at every step.

From the first steps of design, where ideas take shape, to advanced prototyping and seamless iteration, our optimization services provide the support and expertise you need to bring your vision to life. Whether you’re refining a single product or scaling operations, our solutions ensure your designs transition smoothly from digital models to fully integrated, operational outputs. Together, we’ll transform your processes, allowing you to innovate faster, reduce costs, and stay ahead of the competition.

Comprehensive Solutions: From SOLIDWORKS to PDM and Beyond

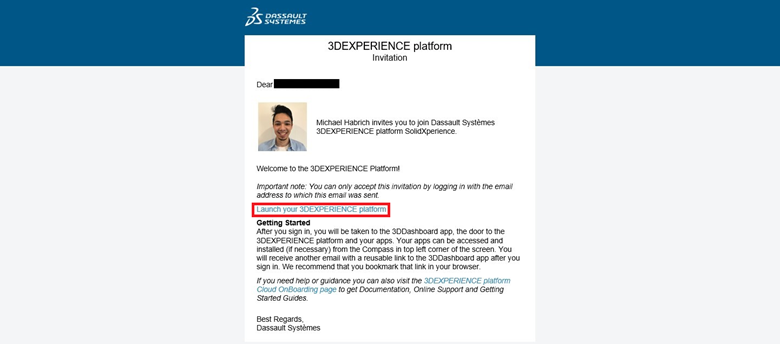

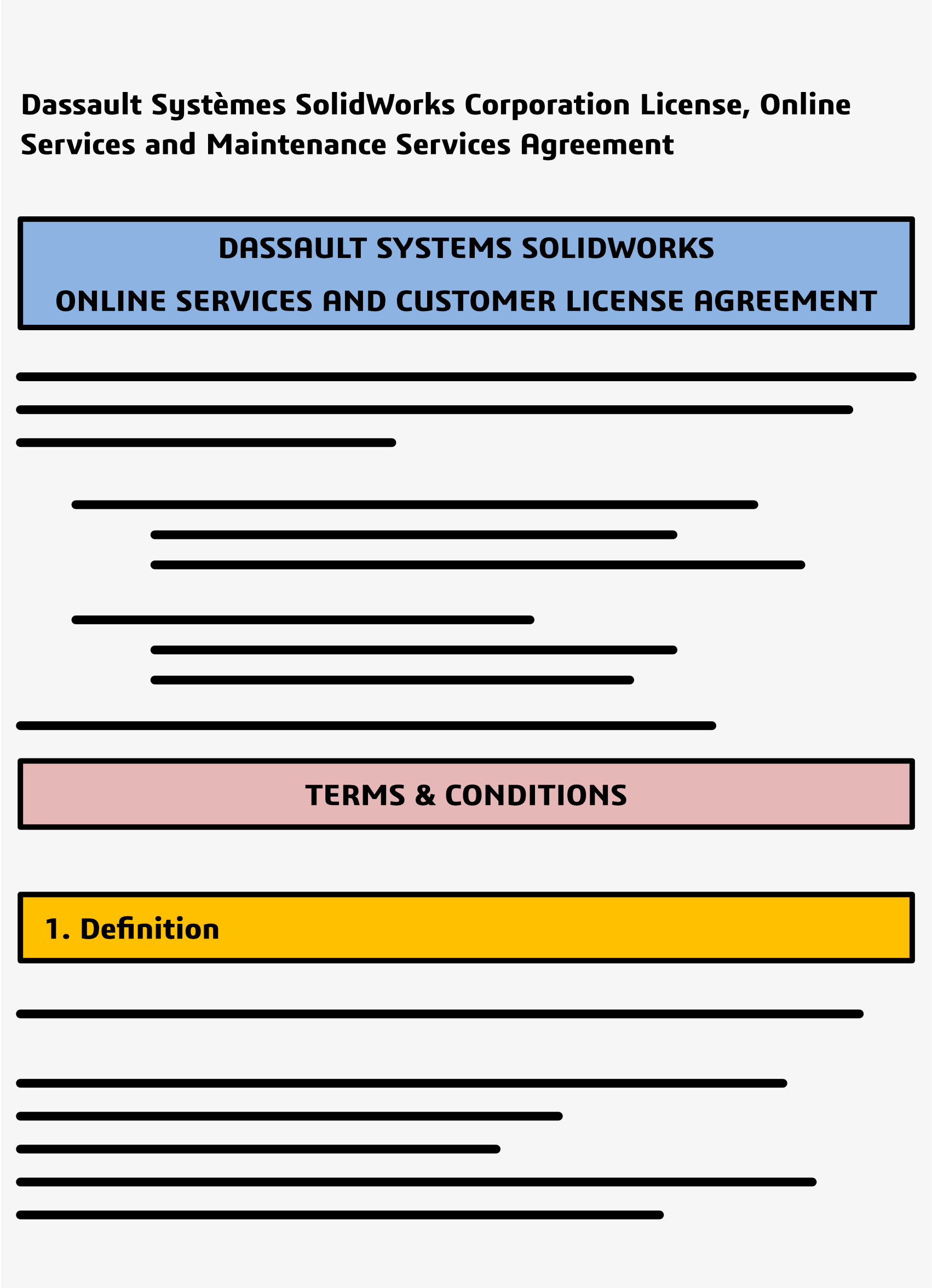

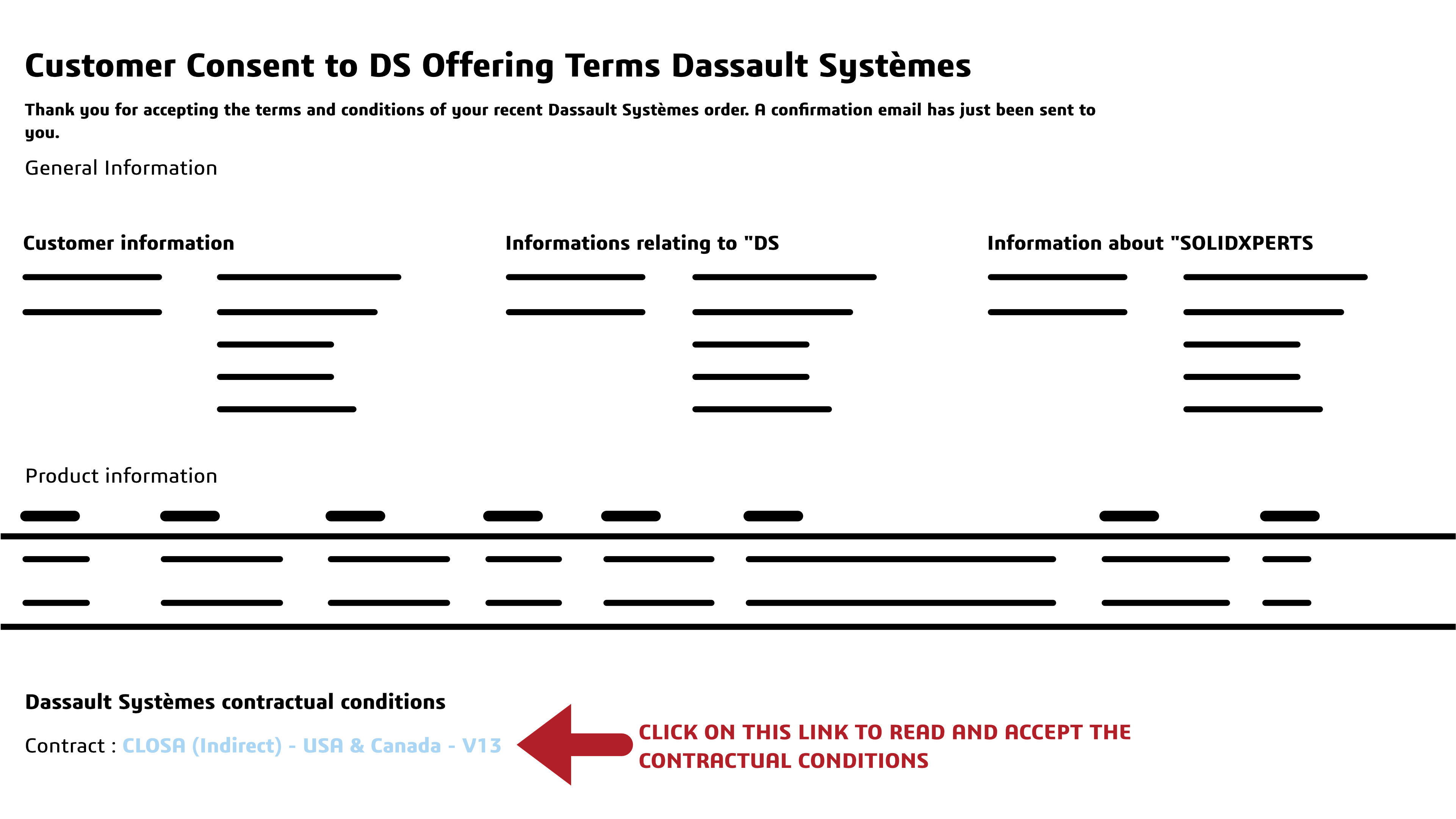

We’re here to ensure our clients have access to the advantage of the comprehensive SOLIDWORKS suite. From secure cloud integration to reintegration processes, we provide robust tools that welcome easy deployment, promotion perks, and simplify complex workflows without the worry of backdating issues.

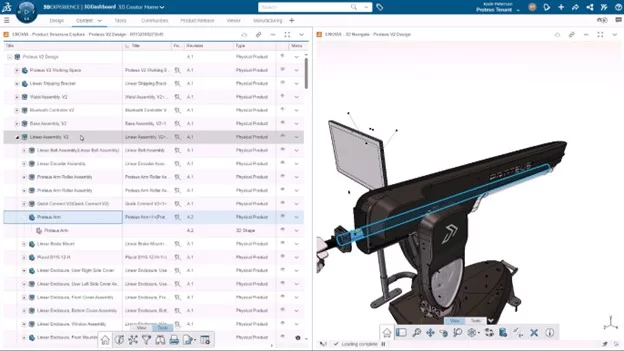

Can Product Data Management Improve Engineering Workflows?

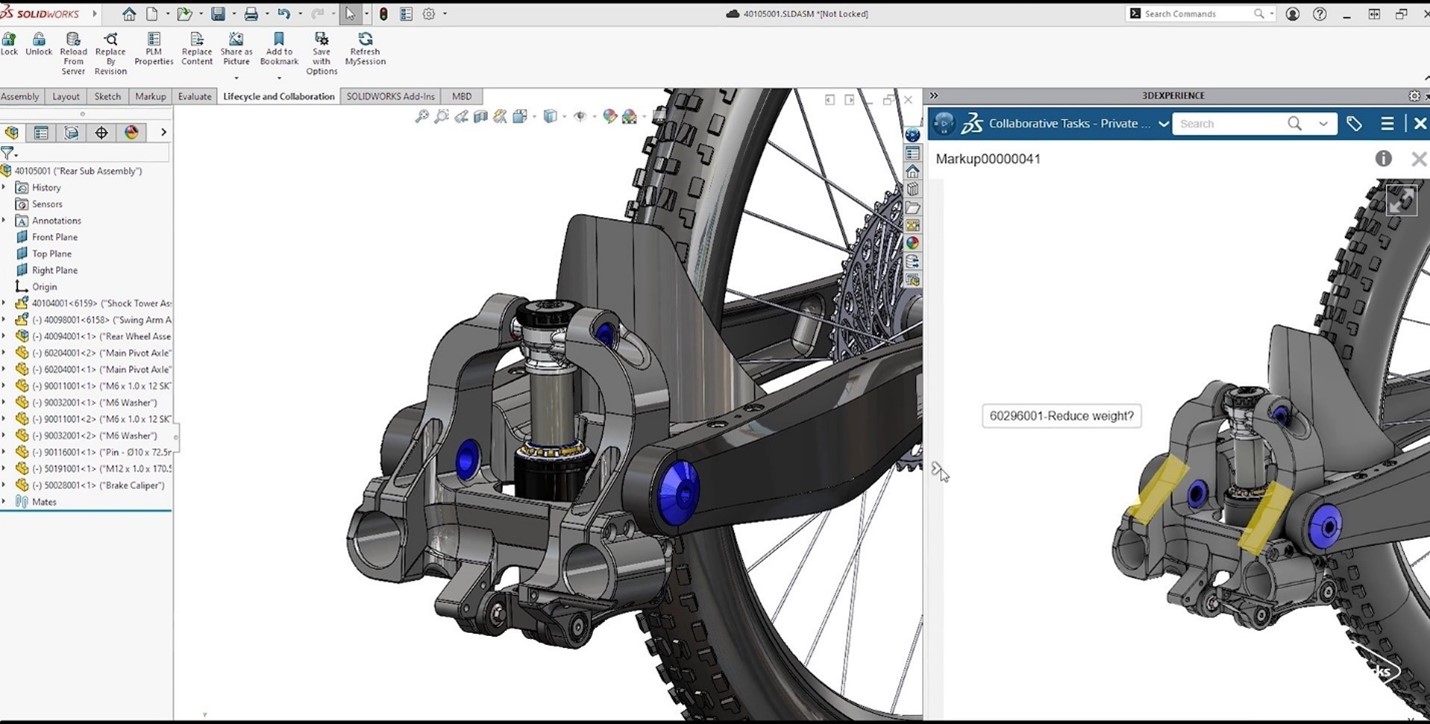

Product data management (PDM) is essential for modern businesses aiming to optimize collaboration and reduce redundancies. Solidxperts’ PDM solutions and services enhance collaboration capabilities, streamline data access, and centralize information, ensuring efficient communication across teams and projects.

Solidxperts for CAD Consulting

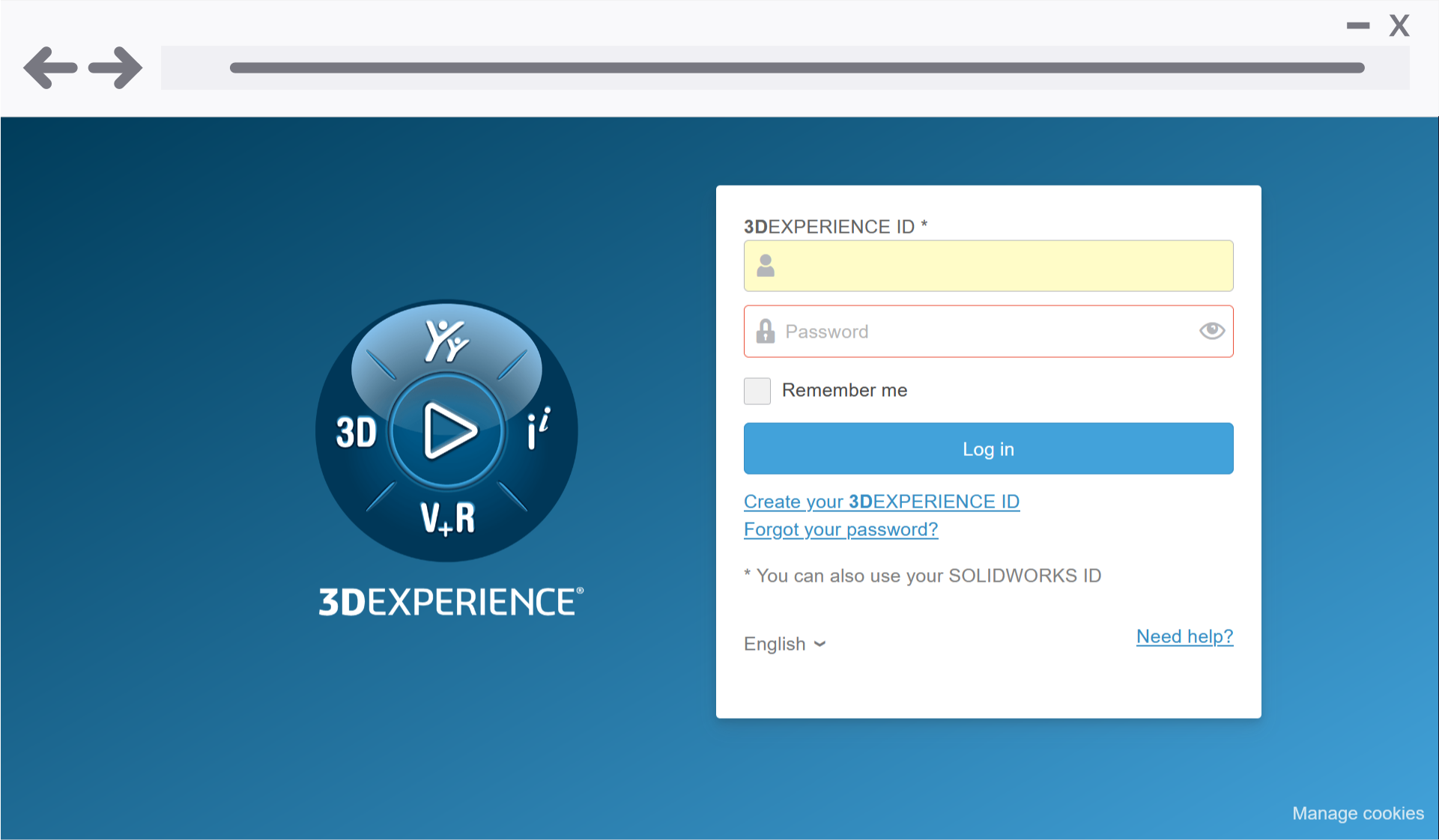

At Solidxperts, we help you unlock the full potential of SOLIDWORKS with access to the latest tools, automatic updates, and expert consulting services, all backed by our industry-leading optimization solutions. From setting up secure cloud data management to ensuring easy deployment, we simplify your engineering workflow while easing the burden of IT administration, allowing you to focus on what matters most — designing and innovating.

Why Businesses Across Canada Trust Solidxperts

Across Canada, we are recognized for our dedication to providing reliable, innovative engineering solutions. Whether it’s SOLIDWORKS CAD, cloud services, or IT administration, we tailor our services to meet the unique needs of businesses of all sizes.

From Nashua to Markham: Regional Expertise

With teams in Nashua, NH, and Markham, Ontario, Solidxperts provides tailored, local support to clients. This proximity ensures quick responses, efficient service, and consistent access to SOLIDWORKS CAD expertise.

Discover Our Promotions

Looking to get the most out of your investment in engineering solutions? At Solidxperts, we offer a range of promotion discounts tailored to meet diverse business needs. Whether you’re acquiring new licenses or taking advantage of the promotion price for bundled solutions, we make it easy to enhance your operations. Simply submit a purchase order during a promotion period to unlock these benefits. Visit our Promotions Page to explore all available offers.

Ready to Elevate Your Business?

Whether you’re a team of SOLIDWORKS veterans or just starting your journey into 3D design, we’re here to help you unlock your full potential. Together, let’s enhance productivity and efficiency across your entire enterprise with tailored solutions that fit your unique business needs.

Contact Solidxperts today, and together, we’ll create a smarter, more efficient future for your business.

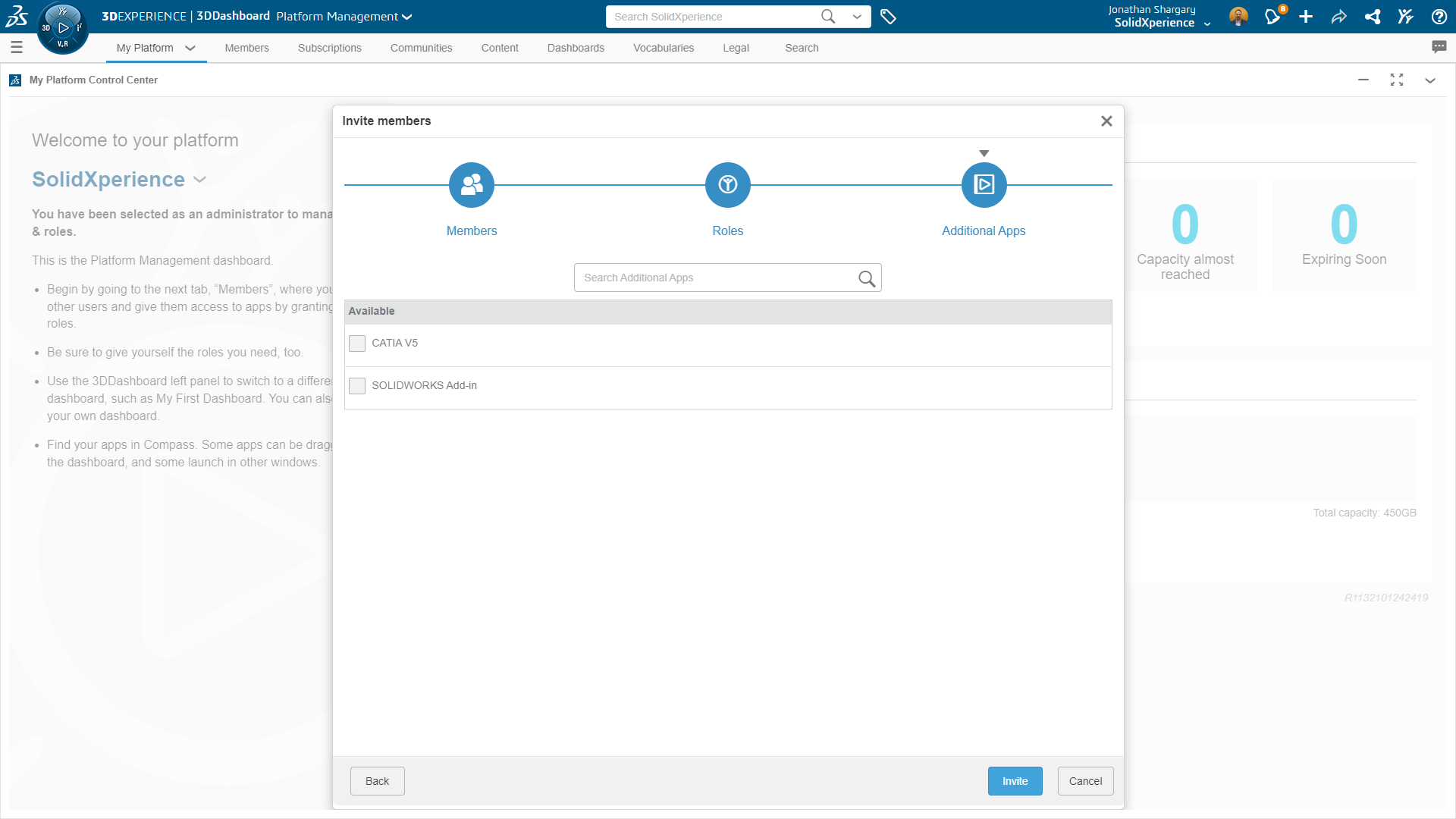

The Value of Cloud-Based Solutions

Both SOLIDWORKS PDM and the 3DEXPERIENCE platform offer cloud-based options, enabling remote teams to collaborate seamlessly. By supporting mobile access and reducing the need for physical servers, cloud integration enhances team members’ ability to access the most current design data.

Comparing Costs

For smaller organizations, SOLIDWORKS PDM is a cost-effective solution, offering basic data management features that integrate with SOLIDWORKS. PLM requires a higher initial investment but pays off with lifecycle management of product data across departments, improving long-term productivity.

Wrapping Up: Choosing the Right Solution

Choosing between SOLIDWORKS PDM vs. PLM on the 3DEXPERIENCE platform depends on your organization’s specific needs. For CAD-centric teams, PDM provides a robust data management system. For teams needing product lifecycle management solutions that encompass every phase of the product development process, the 3DEXPERIENCE platform is an ideal solution.

Ready to Get Started?

SOLIDWORKS 2025 is packed with tools and enhancements to make your design process faster, smarter, and more collaborative. For a quick reference, download the enhancement flyer here and explore more demo videos on the official SOLIDWORKS webpage.

Don’t wait—get ready to elevate your designs with SOLIDWORKS 2025!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene)

PETG (Polyethylene terephthalate glycol)

PETG (Polyethylene terephthalate glycol)

Onyx by Markforged: High Performance Carbon Fiber

Onyx by Markforged: High Performance Carbon Fiber

“It feels like drowning is”, the most common report from the COVID-19 patients requiring breathing assistance, and with that imagery, we took inspiration from the simplicity of a scuba breathing apparatus. The SolidXperience Group officially began tackling the problem on March 23rd, ready to help save the world however they could.

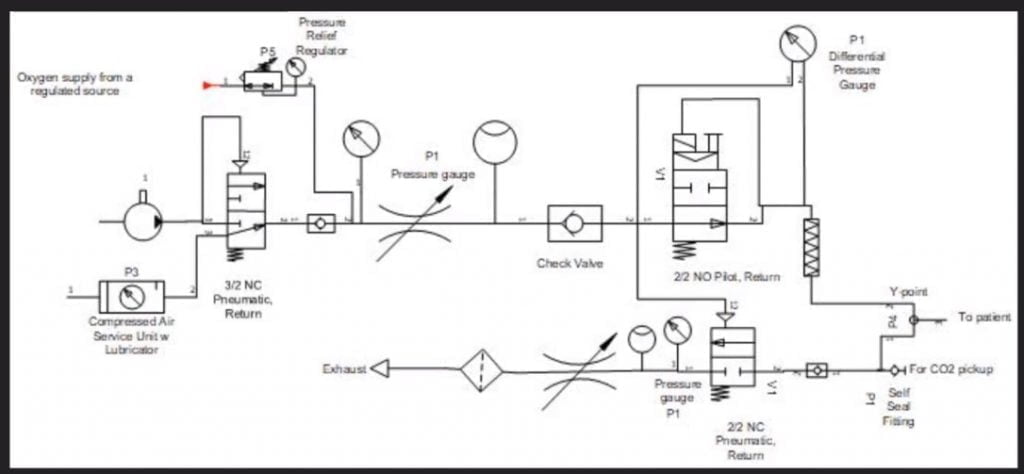

“It feels like drowning is”, the most common report from the COVID-19 patients requiring breathing assistance, and with that imagery, we took inspiration from the simplicity of a scuba breathing apparatus. The SolidXperience Group officially began tackling the problem on March 23rd, ready to help save the world however they could. The next step was to analyze the given product specifications and start creating schematic diagrams defining the required parts and showing how those parts interact to create the desired results. With the help of the project’s panel of medical advisors, the group was able to take the initial schematic designs and modify them as a collaborative team. All online!

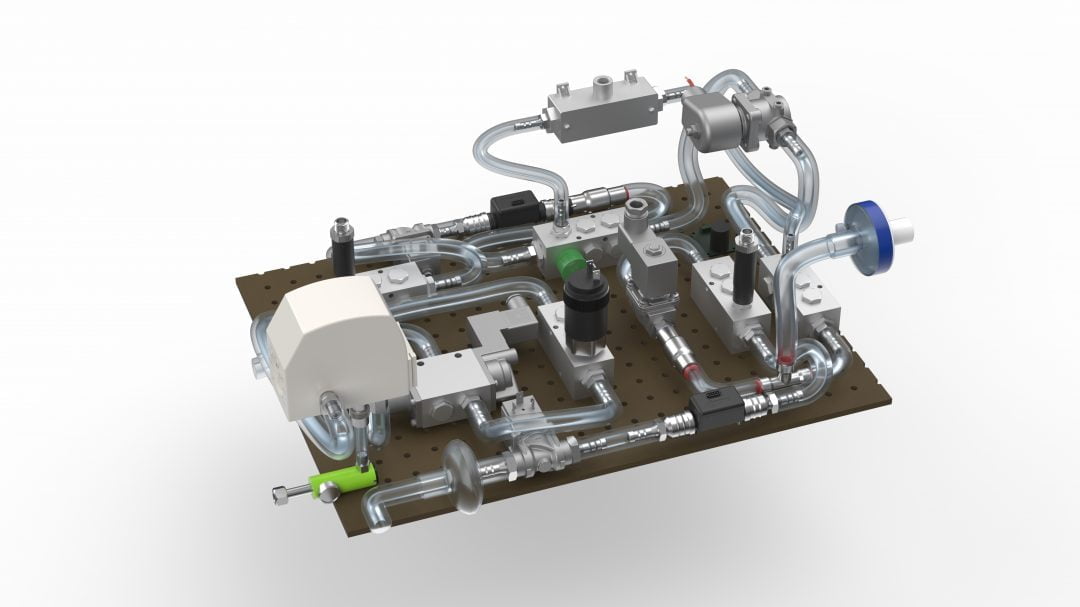

The next step was to analyze the given product specifications and start creating schematic diagrams defining the required parts and showing how those parts interact to create the desired results. With the help of the project’s panel of medical advisors, the group was able to take the initial schematic designs and modify them as a collaborative team. All online! Next, packaging: getting all the required components to fit into a manageable, transportable, robust, easy-to-operate, and reliable case. Under the pressure of the CODE LIFE contest entry submission date of March 31st, this process was successfully started and completed on March 30th. Concurrently, the digital interface was coded to manage the internal valves, solenoids, and sensors necessary to provide a clear and secure on/off readout and warning alarms.

Next, packaging: getting all the required components to fit into a manageable, transportable, robust, easy-to-operate, and reliable case. Under the pressure of the CODE LIFE contest entry submission date of March 31st, this process was successfully started and completed on March 30th. Concurrently, the digital interface was coded to manage the internal valves, solenoids, and sensors necessary to provide a clear and secure on/off readout and warning alarms. The fight isn’t over yet, however! In the coming weeks, several more steps need to be taken quickly to meet the hopeful deadline of May 1st for a functioning prototype. As the physical pieces of the first construction are gathered the interface code must be tested and refined, and the assembly must go through a series of tests and simulations to determine that it meets pre-set standards and can be labeled ‘medical grade’.

The fight isn’t over yet, however! In the coming weeks, several more steps need to be taken quickly to meet the hopeful deadline of May 1st for a functioning prototype. As the physical pieces of the first construction are gathered the interface code must be tested and refined, and the assembly must go through a series of tests and simulations to determine that it meets pre-set standards and can be labeled ‘medical grade’.