TL;DR

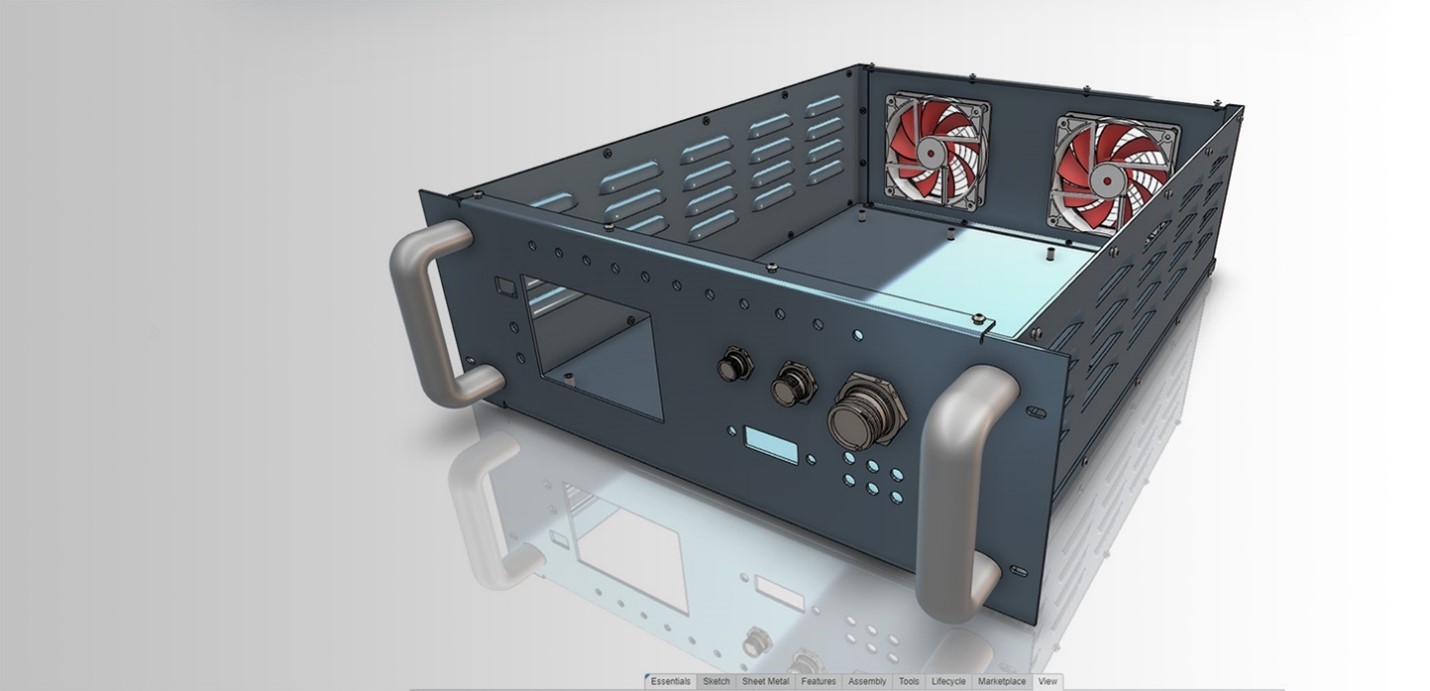

Cloud Services for SOLIDWORKS revolutionize the way engineers and designers work by streamlining collaboration, data management, and project control. Say goodbye to outdated file transfers, version control nightmares, and time-consuming administrative tasks. With seamless real-time collaboration, secure cloud-based storage, and integrated project workflows, SOLIDWORKS users can focus more on innovation and design. Whether sharing models, managing revisions, or coordinating across teams, Cloud Services enhance efficiency, ensuring a smoother product development process.

Download the SOLIDWORKS Productivity Guide

Finding More Time for Design

Today’s engineers and designers face constant interruptions—meetings, emails, file management issues, time tracking, and version control headaches. With increasing project complexity, market competition, and the demand for innovation, maximizing productivity is more crucial than ever.

Studies have shown that design engineers spend only a fraction of their working hours on actual design work. The rest of their time is spent on administrative tasks, tracking files, and managing data. This inefficiency not only slows down innovation but also impacts bottom-line productivity.

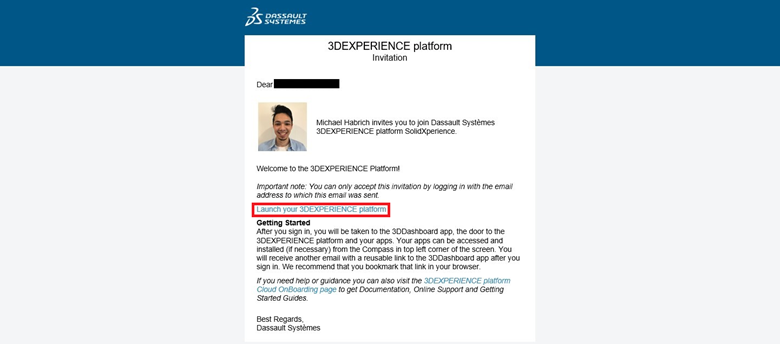

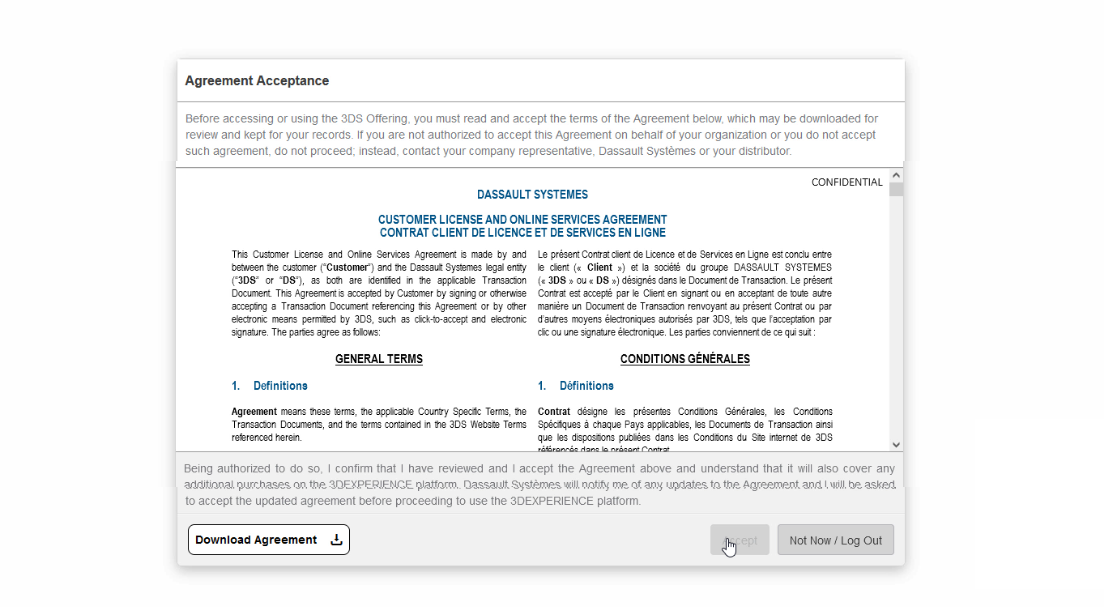

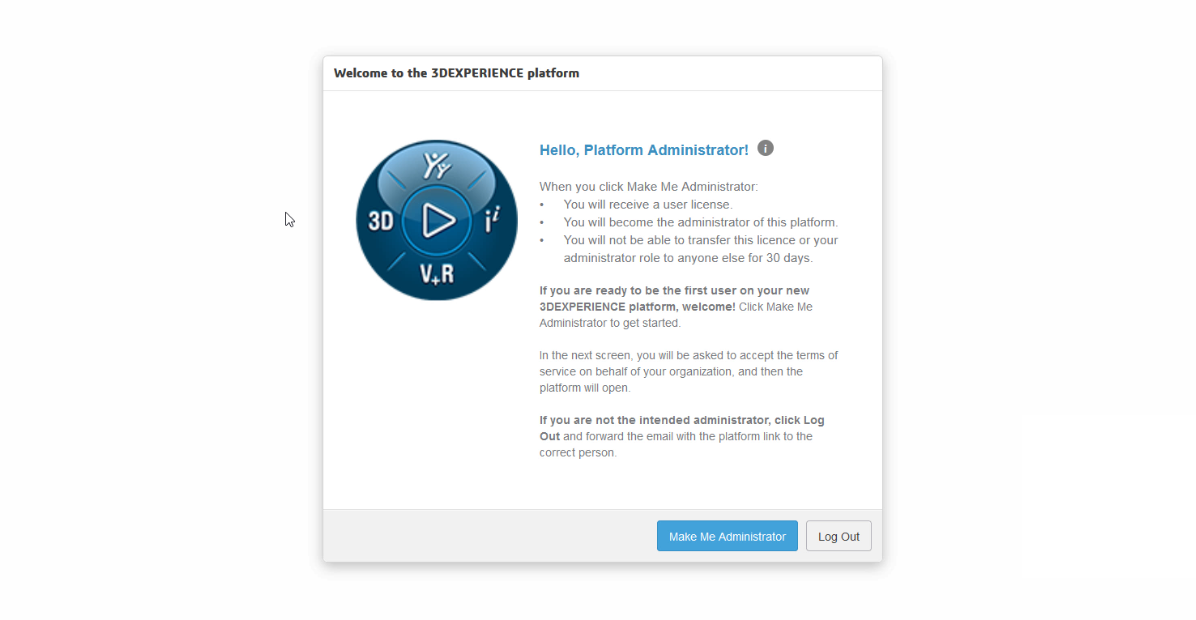

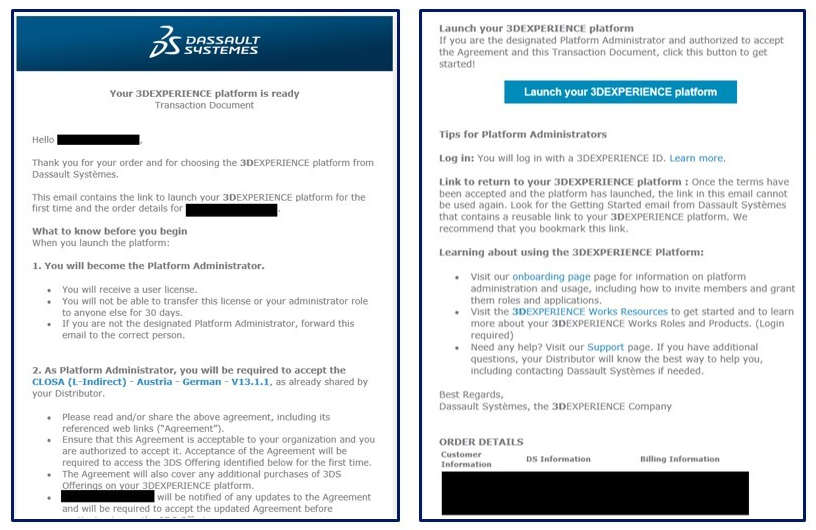

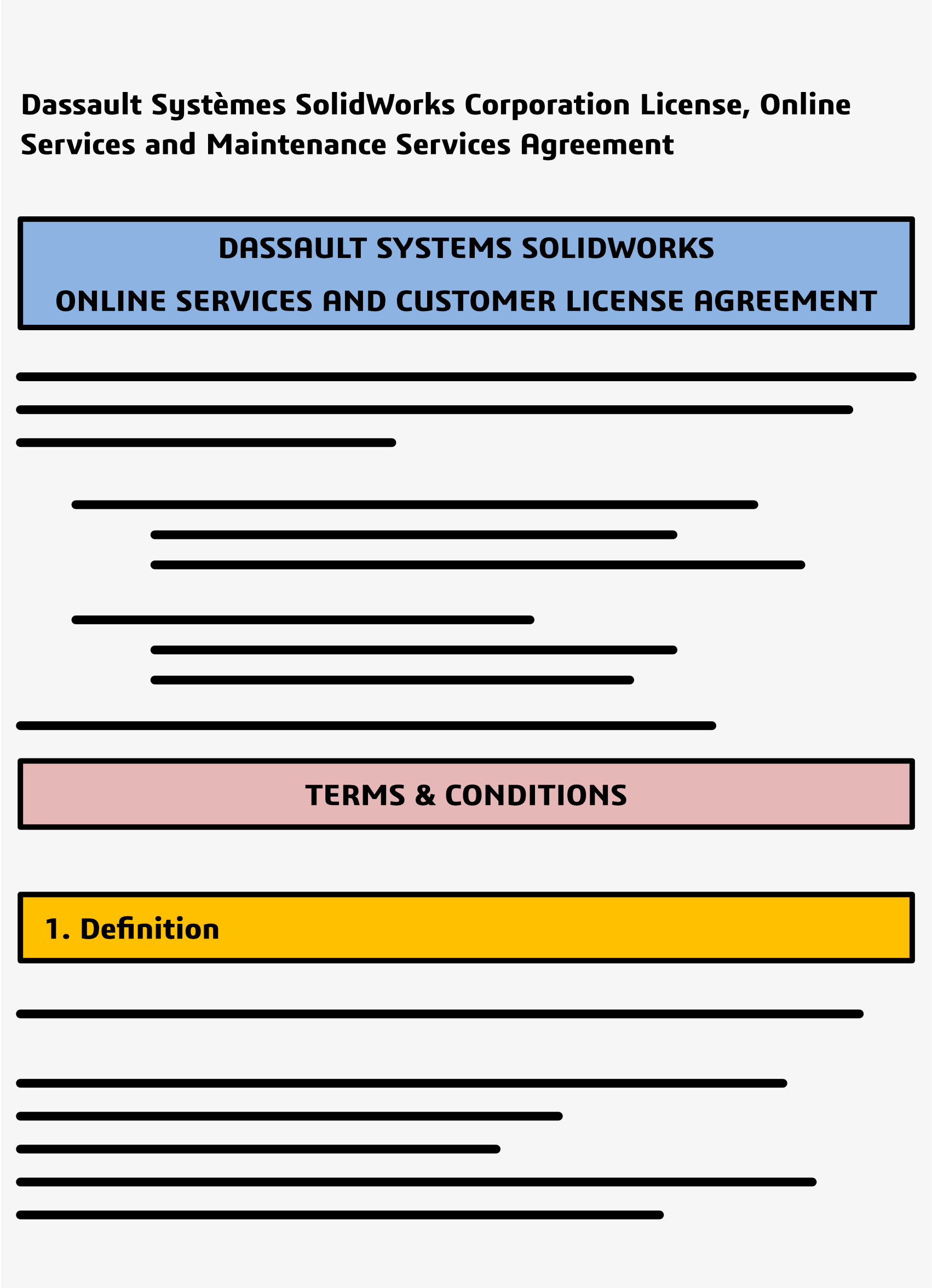

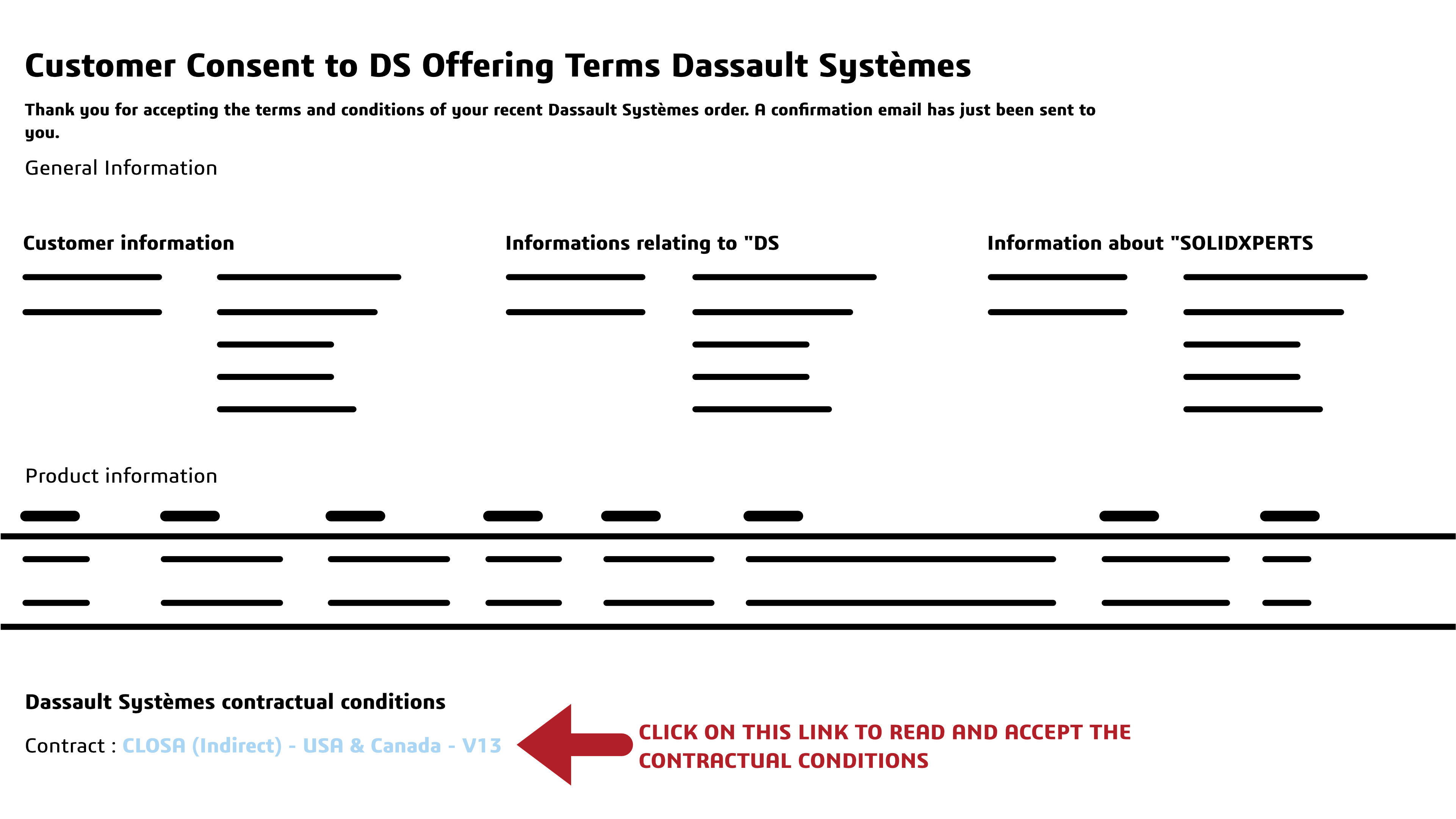

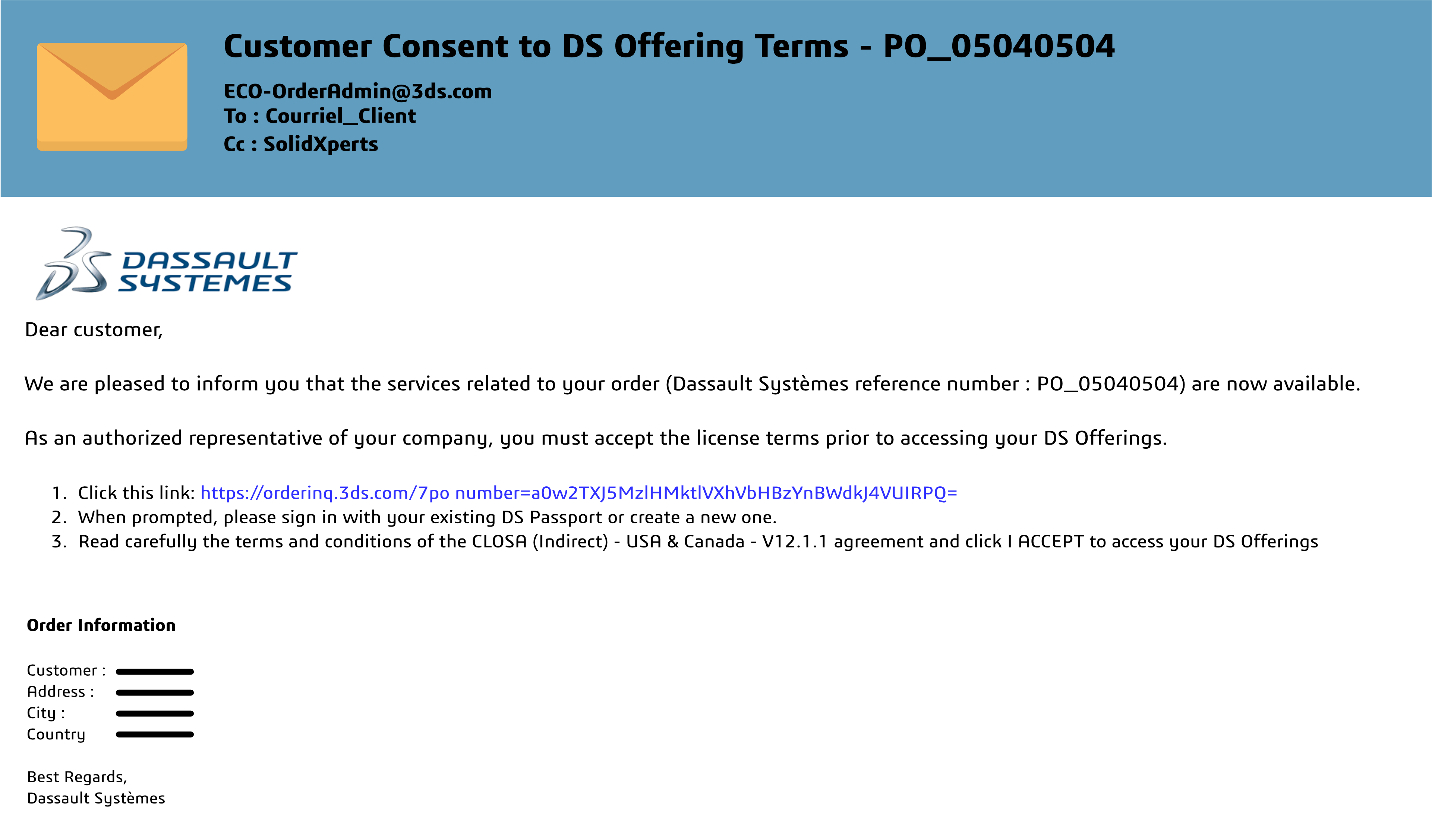

Thankfully, SOLIDWORKS provides a solution. With every new SOLIDWORKS 3D CAD license, users gain access to Cloud Services, a powerful suite of tools that removes many of the barriers that slow down the design process. By connecting to the 3DEXPERIENCE platform, these tools streamline collaboration, data management, and project workflows, allowing engineers to focus on what truly matters: designing.

Let’s explore how Cloud Services for SOLIDWORKS can enhance your workflow, improve efficiency, and eliminate traditional design bottlenecks.

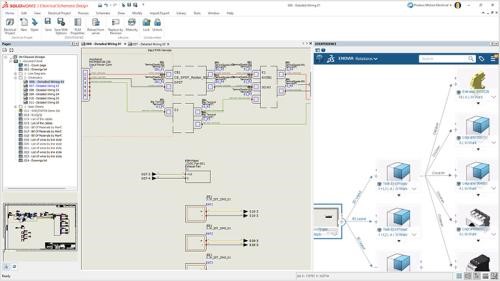

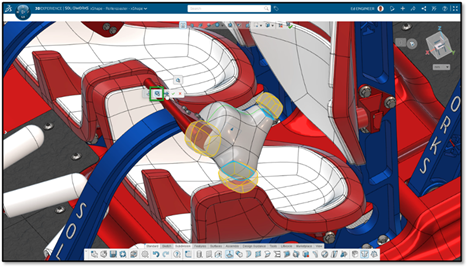

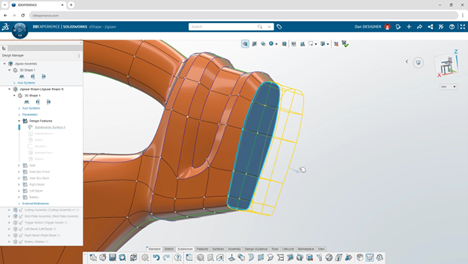

Seamless Collaboration with Share and Markup

Traditional design sharing methods often involve cumbersome file transfers, requiring recipients to have the right software to open and review CAD files. This process can lead to delays, miscommunication, and even file compatibility issues.

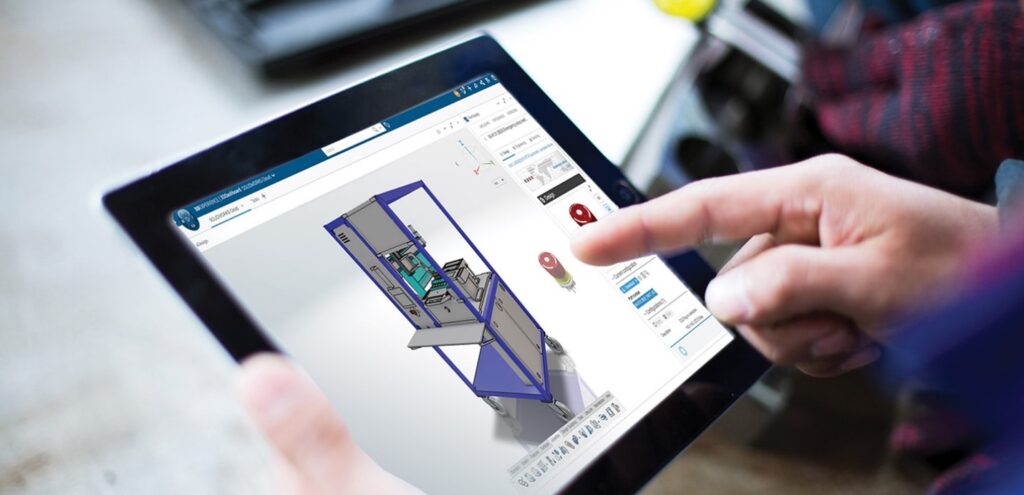

With Cloud Services, SOLIDWORKS users can instantly share 3D models with collaborators via a secure web-based link. This eliminates the need for physical file transfers and special viewing software. Internal teams, external suppliers, customers, or stakeholders can view, annotate, and discuss designs in real-time—even without a SOLIDWORKS license.

The Impact of Faster Collaboration

Collaboration is one of the biggest challenges in product development. Miscommunication between designers, engineers, and clients can lead to costly errors and significant project delays. With traditional workflows, waiting for feedback from multiple stakeholders can stretch project timelines unnecessarily.

By integrating real-time feedback loops through Share and Markup, Cloud Services ensure that everyone is working on the latest version of a design, reducing errors and streamlining decision-making. The ability to provide immediate feedback accelerates the design iteration process, leading to faster innovation cycles.

- Faster design iterations with immediate feedback

- Reduced miscommunication by centralizing design discussions

- Easy access for non-CAD users through a simple web browser

- Improved documentation with markup history and feedback logs

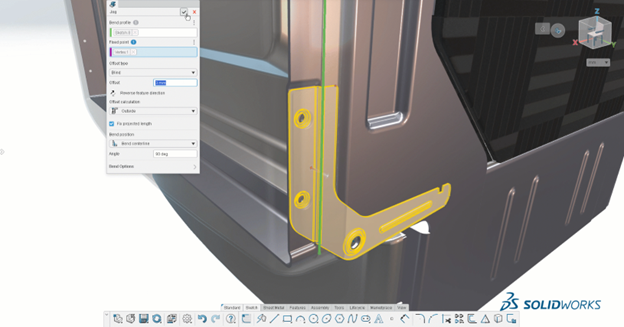

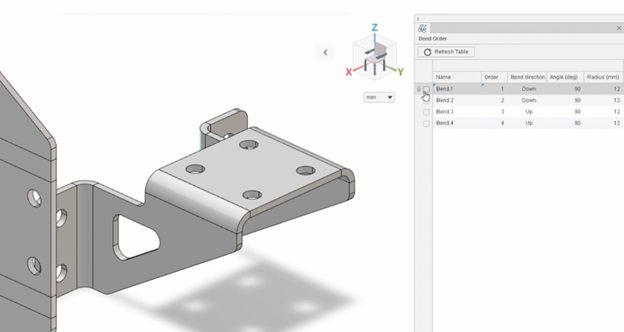

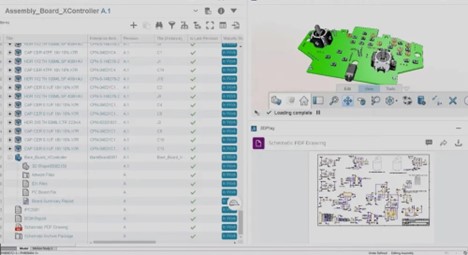

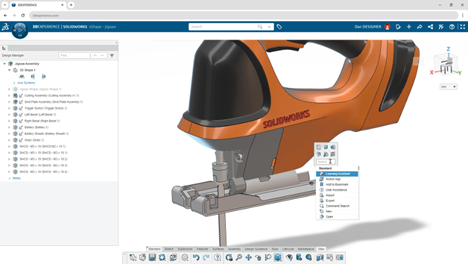

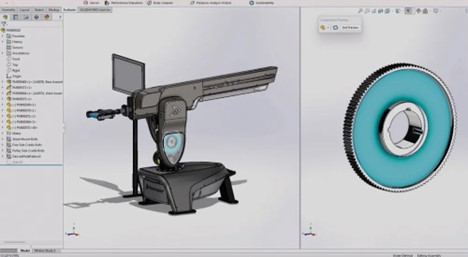

Store and Revise: The Power of Cloud-Based Data Management

File mismanagement is a significant timewaster in engineering workflows. Searching through emails for the right file version or accidentally working on an outdated model can lead to costly errors and project delays.

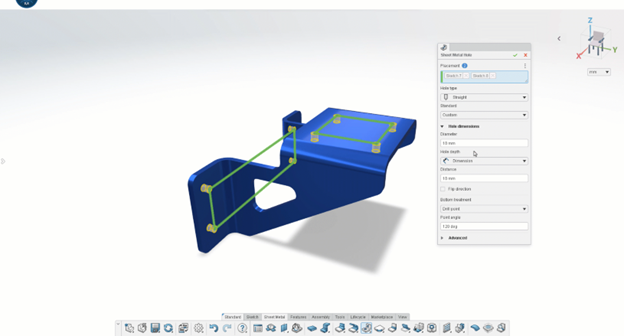

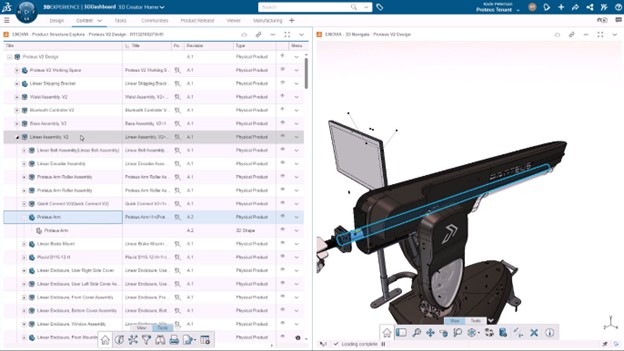

By connecting SOLIDWORKS to the 3DEXPERIENCE platform, Cloud Services provide secure, CAD-aware online storage that ensures:

- Always-accessible, up-to-date design files

- Elimination of duplicate or lost files

- Streamlined revision control with automated version tracking

The Hidden Costs of Poor File Management

Data mismanagement costs engineering teams valuable hours. Research suggests that professionals spend nearly 20% of their workweek searching for information rather than working on productive tasks. This inefficiency can be costly, especially for companies that rely on fast turnaround times.

With Cloud Services, SOLIDWORKS users gain a single source of truth for their data. Files are always up to date, accessible from anywhere, and backed up securely. Revision tracking ensures that outdated designs never make their way into production, avoiding costly errors and wasted resources.

Additionally, features like revision bumping and check-out/check-in functionality help prevent team members from overwriting each other’s work, creating a more structured and reliable workflow.

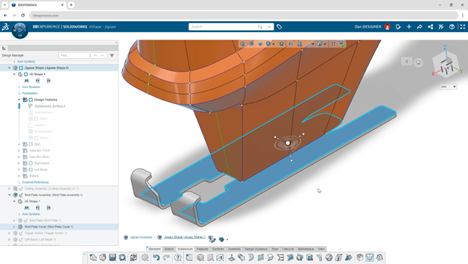

Manage and Control: Keep Your Projects on Track

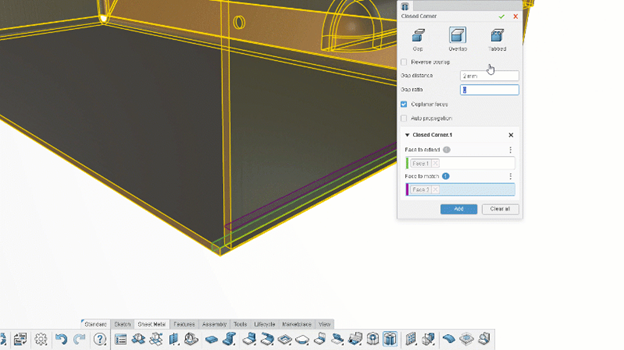

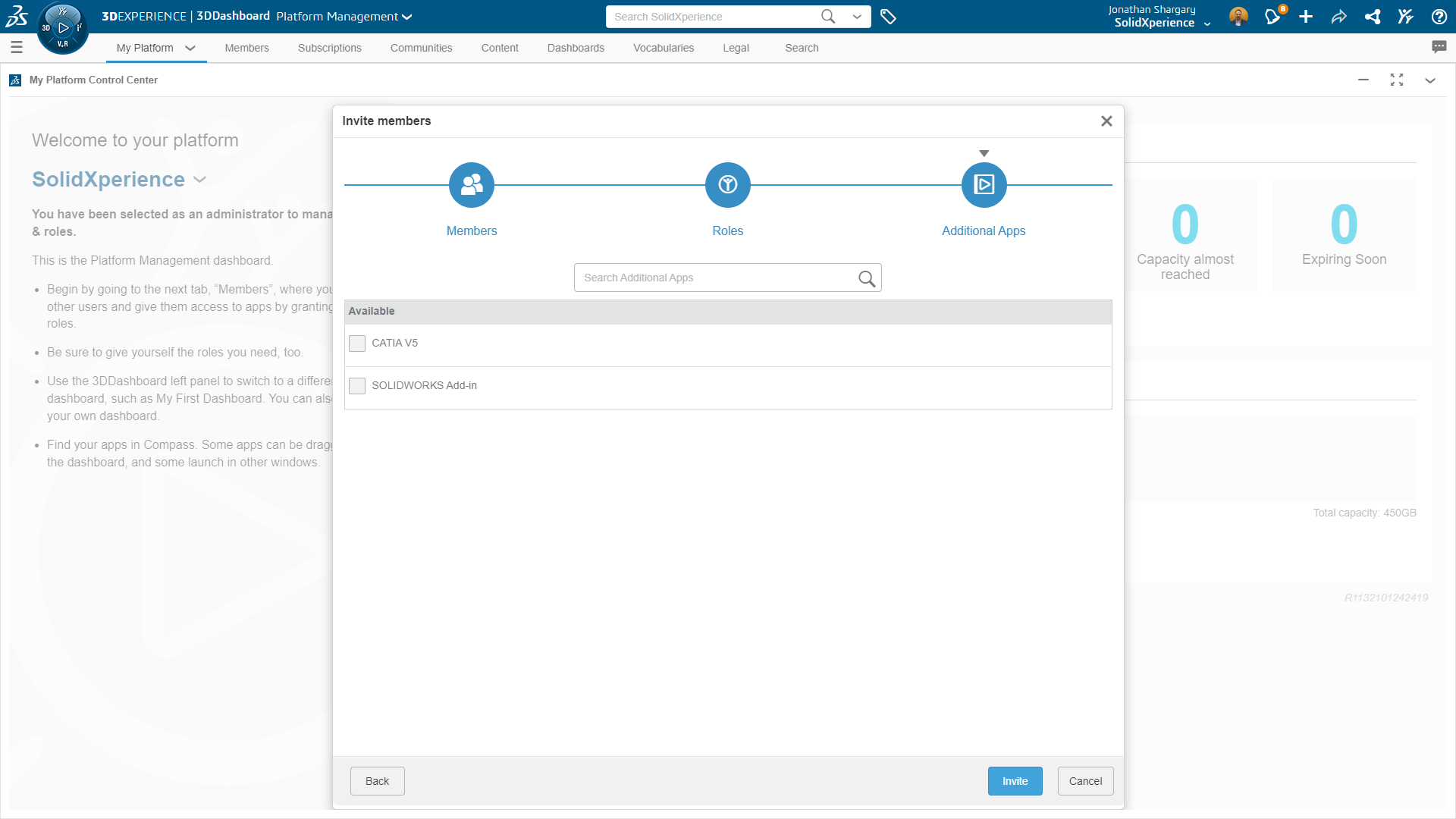

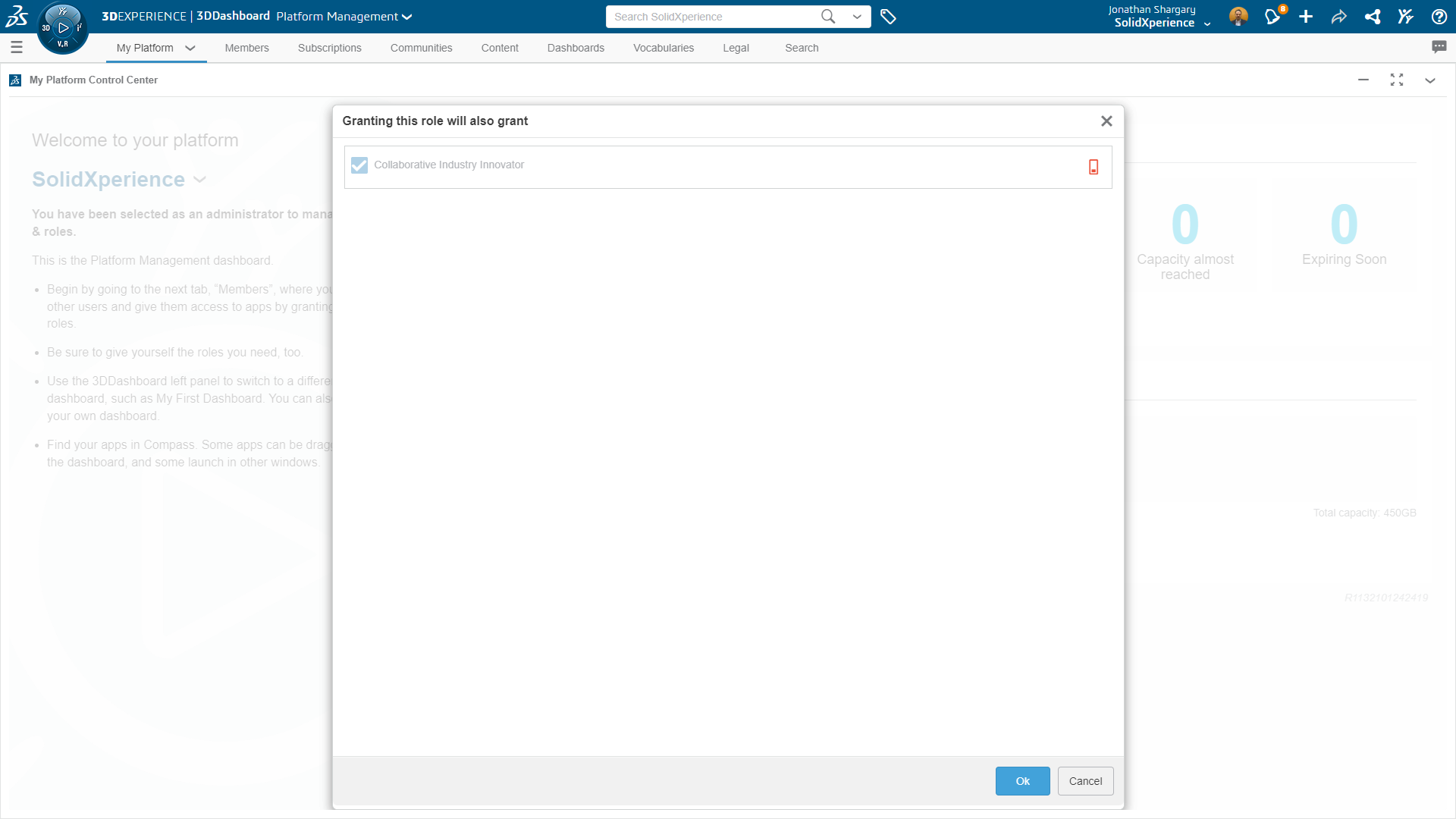

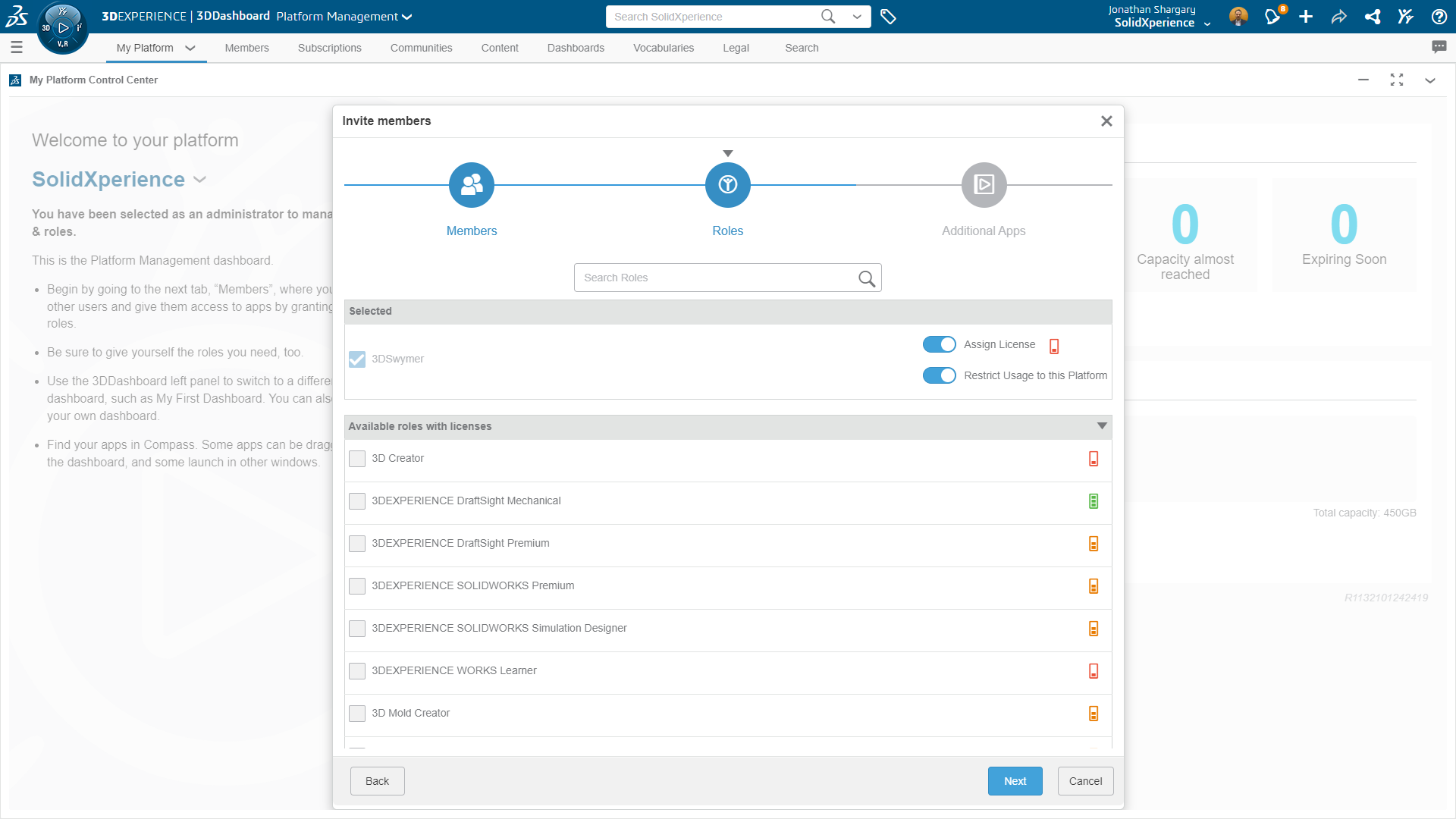

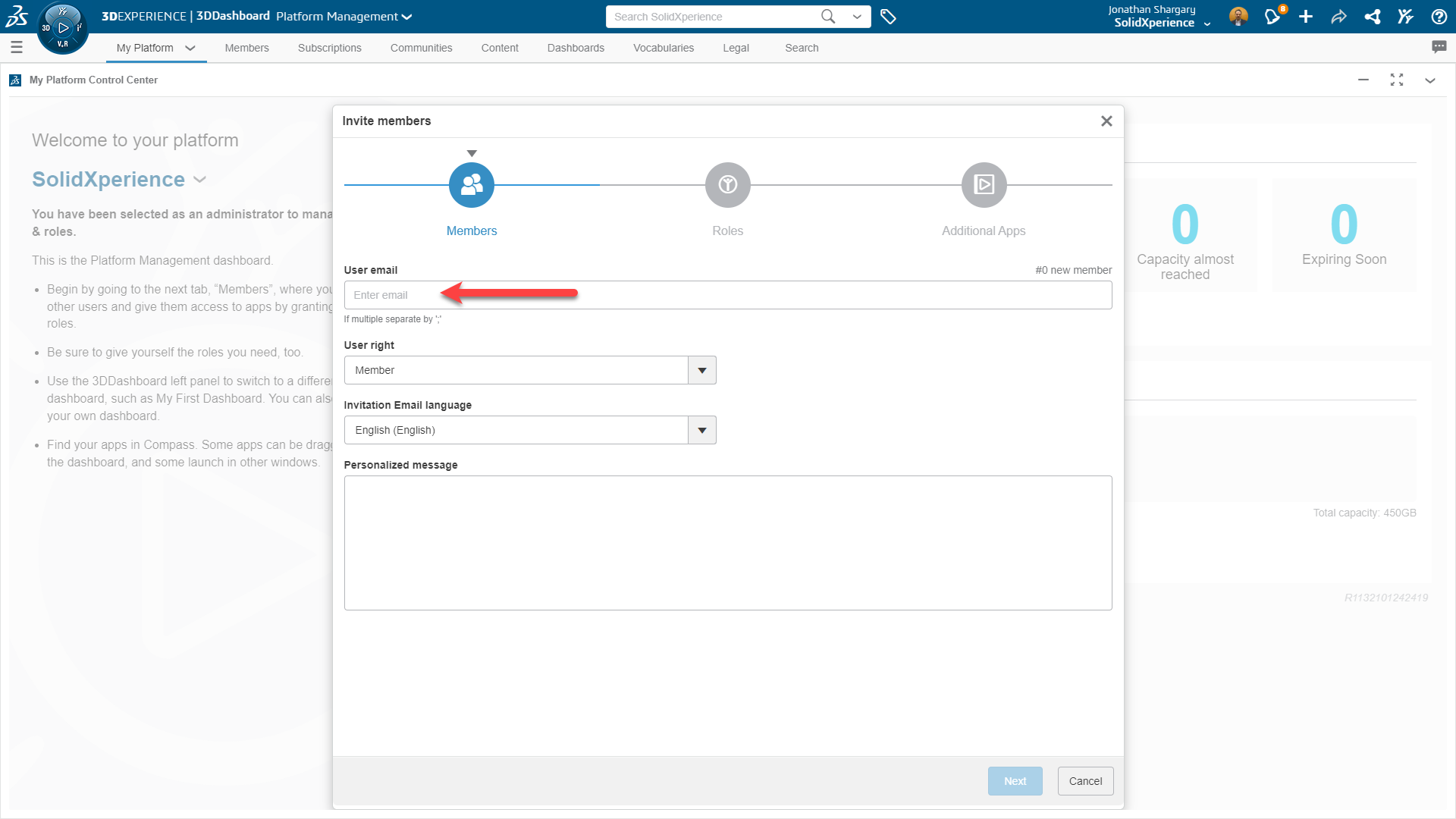

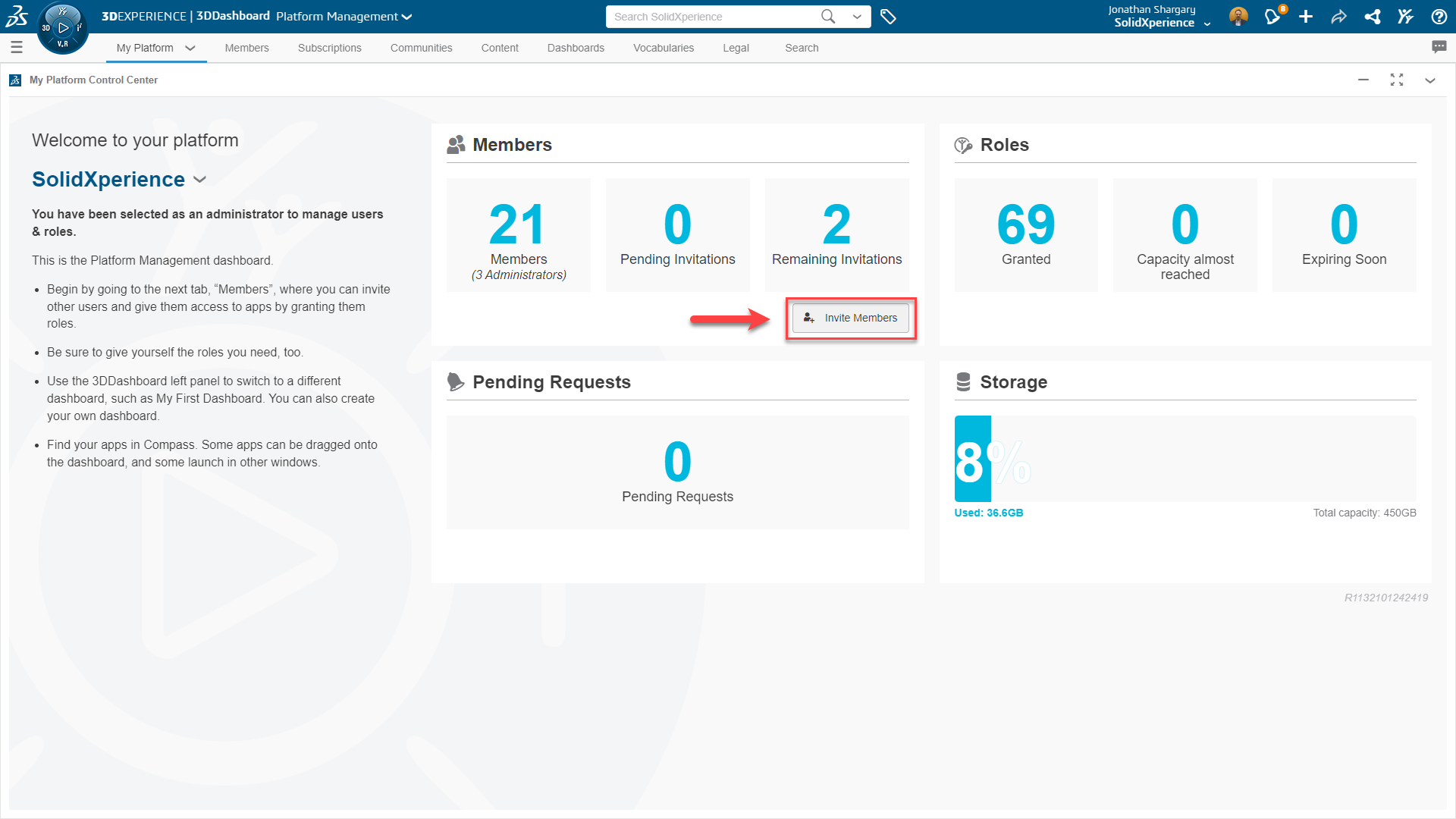

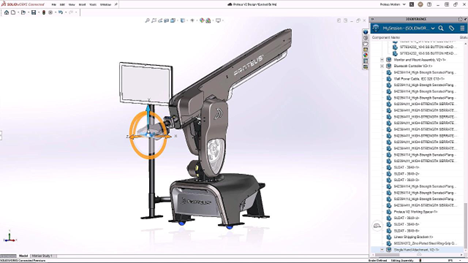

For teams working on complex product designs, effective change management and workflow control are essential. The Cloud Services integration within SOLIDWORKS allows users to:

- Track design progress and manage approvals directly from within SOLIDWORKS

- Assign and review tasks in real-time

- Control data access and user permissions to maintain security and organization

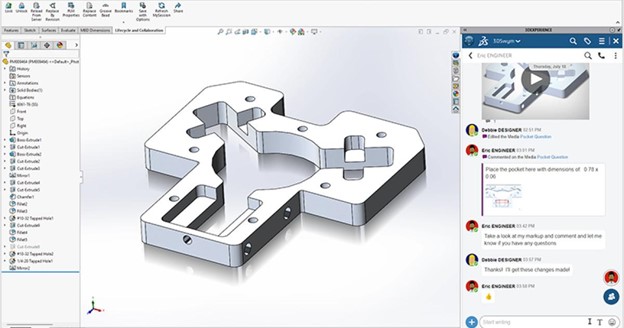

Automating Workflows for Greater Efficiency

Manual processes, such as approving design changes, tracking tasks, and managing data permissions, often slow down progress. By automating these workflows, Manage and Control on the 3DEXPERIENCE platform removes bottlenecks and allow projects to move forward seamlessly. Teams can quickly approve changes, manage access rights, and oversee project progress without the need for lengthy email chains or unnecessary meetings.

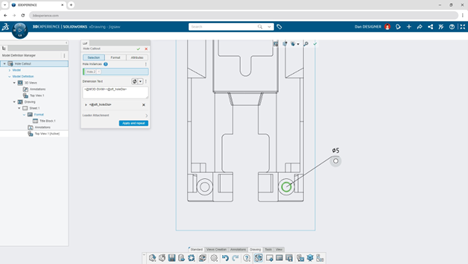

Real-Time Collaboration: Breaking Down Communication Barriers

Engineering teams are often distributed across multiple locations, making real-time collaboration difficult. Traditional workflows involve passing files back and forth, leading to delays and version control conflicts.

With Cloud Services, SOLIDWORKS users can:

- Connect instantly to team dashboards, messaging, and activity streams

- Drag-and-drop tasks for streamlined project tracking

- Work on a single shared dataset from day one, eliminating redundancy

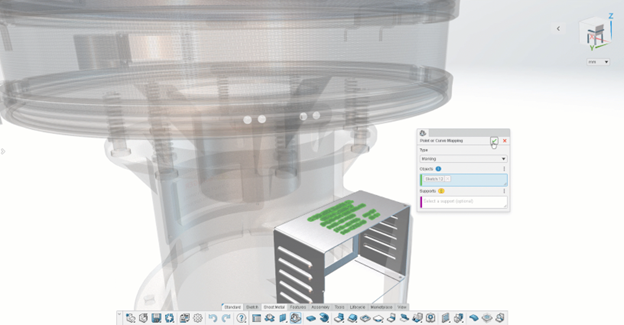

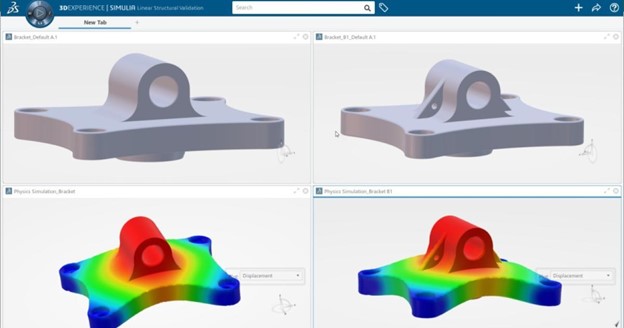

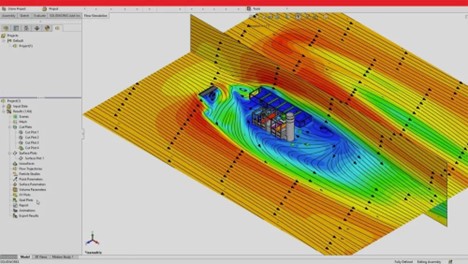

Access to New Product Development Tools

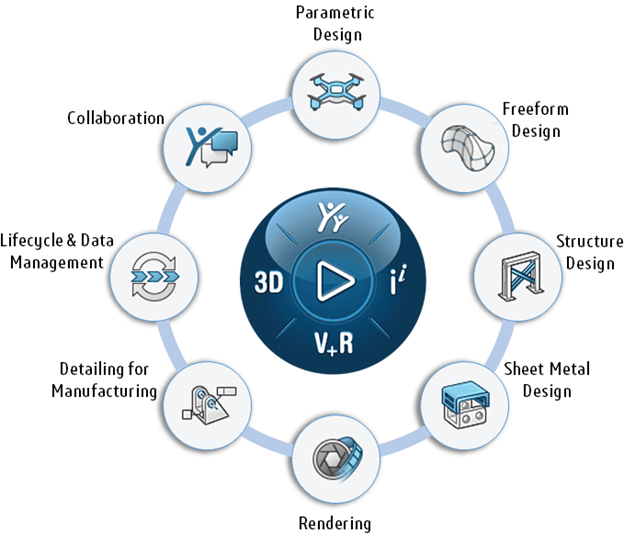

Beyond core collaboration and file management features, Cloud Services offer a gateway to 3DEXPERIENCE Works, an extended suite of industry-leading tools for:

- Advanced design and simulation

- Integrated data and lifecycle management

- Optimized manufacturing processes

Ready to Take Your SOLIDWORKS Workflow to the Next Level?

Imagine a workday where you can focus entirely on what you love—designing—without being bogged down by file chaos, endless emails, or version control headaches. That’s exactly what Cloud Services for SOLIDWORKS offers.

With real-time collaboration, secure cloud storage, and effortless project management, you can streamline your workflow, reduce errors, and free up valuable time for more creative problem-solving.

The future of design isn’t just about creating better products—it’s about working smarter, faster, and more efficiently. Cloud Services for SOLIDWORKS puts control back in your hands, letting you focus on innovation while eliminating the distractions of outdated processes.

So, why wait? Take the next step today. Whether you’re a solo designer or part of a growing engineering team, Cloud Services can revolutionize the way you work.

Download the SOLIDWORKS Productivity Guide

Interested in unlocking the full potential of your design process? Contact Solidxperts today to learn how Cloud Services can enhance your SOLIDWORKS experience!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Marc Raibert, a lifelong roboticist, has been at the forefront of robotics innovation for over 50 years. As the founder of Boston Dynamics, he led the creation of iconic robots like BigDog, Atlas, and Spot, which revolutionized dynamic mobility. He founded The AI Institute in 2022 to advance intelligent robotics. Raibert’s career highlights include tenure at MIT and Carnegie Mellon University, pioneering dynamic robot research at the Leg Laboratory, and earning accolades like the IEEE Robotics Pioneer Award and the Engelberger Award. His inspiring journey continues to shape the future of robotics and AI.

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action!

Spot, the versatile robotic platform, will make a special appearance at 3DEXPERIENCE World 2025. Known for its dynamic mobility and adaptability, Spot has garnered fame for its ability to navigate diverse environments, carry payloads, and even climb stairs with ease. This particular Spot, nicknamed “One”, has achieved celebrity status, starring in a Billie Eilish music video and even making an appearance in renowned sci-fi franchise, Black Mirror. Don’t miss the chance to see Spot live in action! Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies.

Gian Paolo Bassi – With over 25 years in the 3D, CAD, and PLM industries, Gian Paolo Bassi drives innovation as 3DEXPERIENCE Works SVP & Customer Role Experience. Previously SOLIDWORKS CEO, he spearheaded groundbreaking developments in cloud-based design. Before Dassault Systèmes, he founded RIWEBB and co-invented multiple patents at ImpactXoft, showcasing his passion for advancing functional modeling and collaboration technologies. Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC.

Suchit Jain – Vice President of Strategy & Business Development, Suchit Jain leads the cloud transformation and 3DEXPERIENCE Works expansion of SOLIDWORKS, focusing on product and sales strategies. He also oversees the User Advocacy team, supporting SOLIDWORKS’ passionate global community. A mentor and advocate for startups, Suchit actively engages with innovation hubs like Greentown Labs and MassChallenge, driving collaboration between entrepreneurs and resources. His academic achievements include a bachelor’s degree from IIT Bombay and a master’s degree in Structural Mechanics from USC. Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.

Manish Kumar – With over two decades at SOLIDWORKS, Manish Kumar has been instrumental in driving innovation. As CEO, he leads the synergy between R&D and SOLIDWORKS’ vibrant user community, fostering adoption of the expanding SOLIDWORKS portfolio. From pioneering developments in sketching and modeling to introducing V6 technology, Manish has shaped the future of design. A graduate of IIT Delhi and Harvard University, he is also an artist, woodworker, and avid cricket enthusiast, balancing his professional achievements with personal passions.