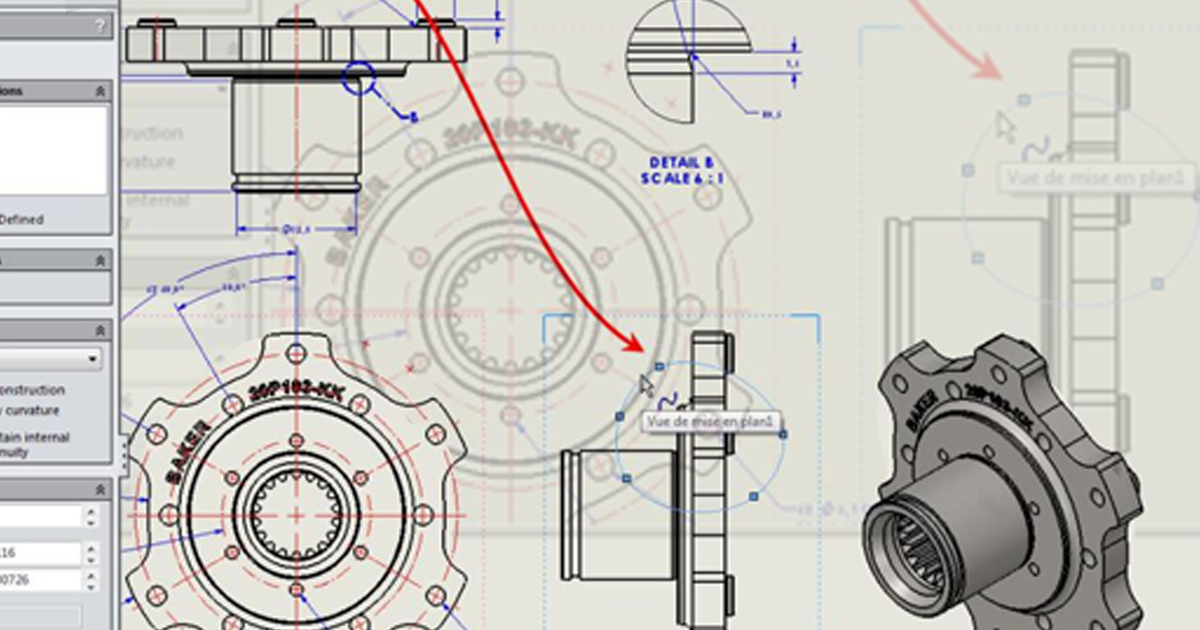

Broken-Out Section View in a Drawing

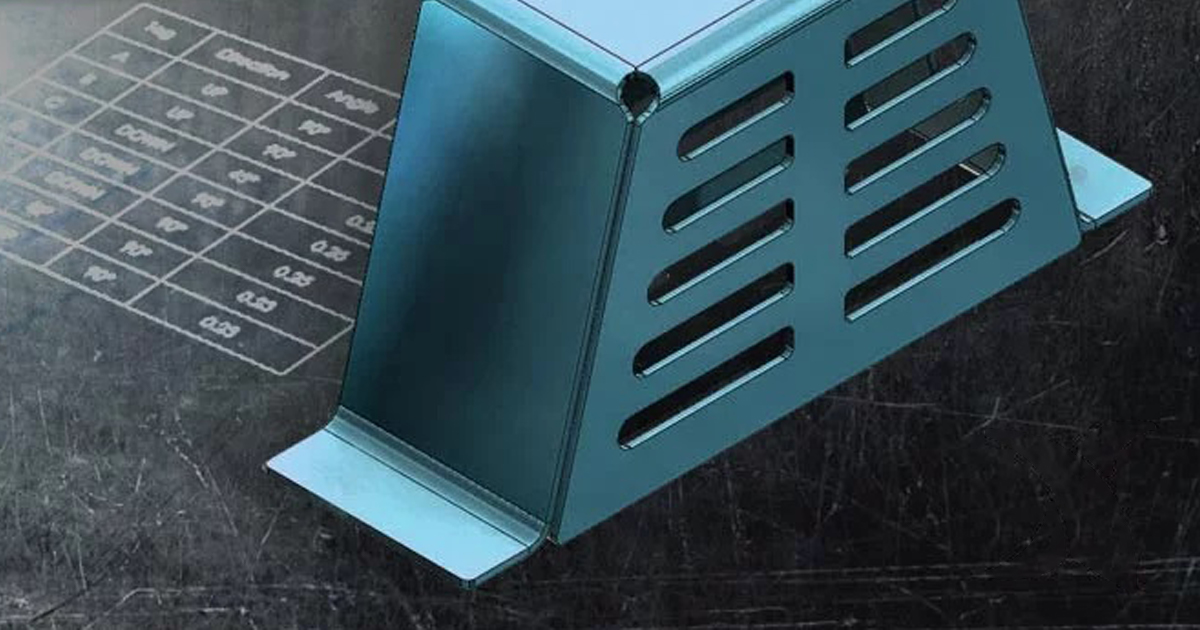

The sheet-metal module included in SolidWorks allows us to create different types of consumer products that are part of our daily lives.

Continue reading “How to create a multi-body sheet metal part from a solid geometry”

The results open in Microsoft Excel in a .tmp file.

From Microsoft Excel, you can (Save As) in the format of your choice.

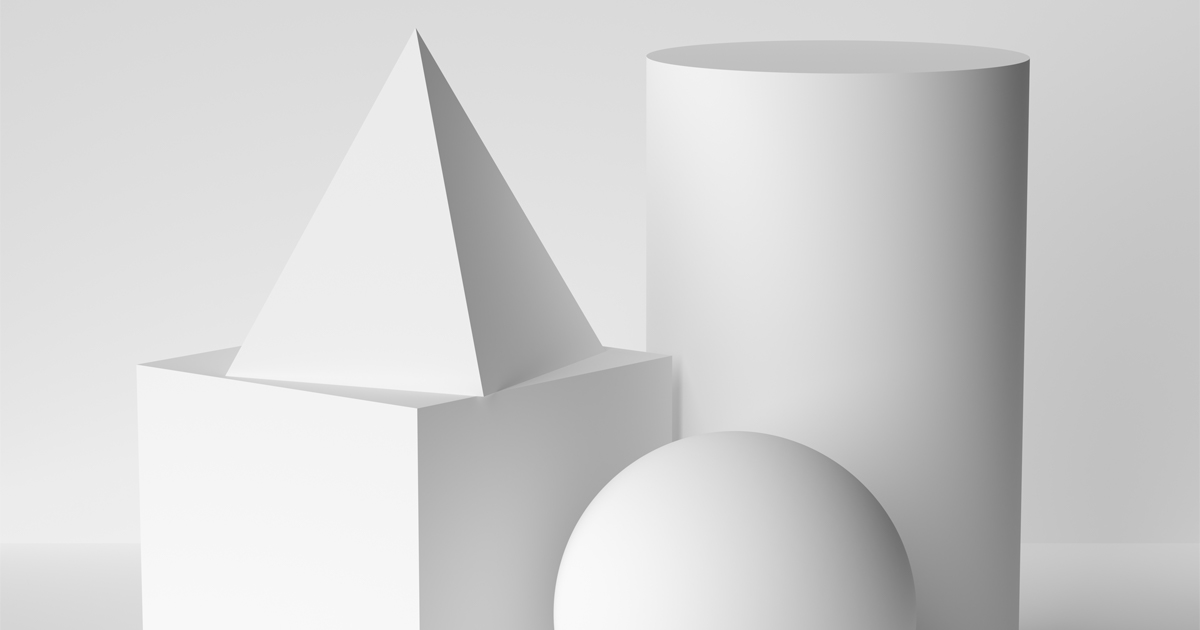

b) Option 2: Export search result

This will export to a .csv file (Type: Comma-Separated Files).

The .csv file will open by default in Microsoft Excel.

It is possible to open the .cvs file with Microsoft Bloc-Notes or any other note editor.

With 25 years of experience and more than 250 certifications, SolidXperts teams can help you become true 3D experts! An additional question? Need information?

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

by Steven Murphy – Application Specialist at SolidXperts

Engineers are always looking for faster and more efficient means of providing manufacturing information for their models. SOLIDWORKS 2019 expansion of Model-Based Definition to sheet metal components allows for designers to integrate the necessary product manufacturing information (PMI) directly into their sheet metal parts.

In any sheet metal part, right-click on the flattened pattern and select ‘Insert bend notes.’ The flattened pattern includes all of the bend notes on the flattened view. This includes the bounding box in the 2D view for easy reference.

Once the bend notes have been created, simply add a bend table from the tables drop-down menu. The bend table can be used to consolidate all of the directions, radii, and bend angles into one location. As with any SOLIDWORKS table, the bend table can be exported as a separate table.

After creating the bend table, the final step of the process is to generate a 3D view with the derived flattened pattern configuration. This 3D view can be used to export to a 3D PDF, Edrawings, or just saved in SOLIDWORKS for anyone to access.

And just like that, SOLIDWORKS MBD has removed an extra step from the design to fabrication workflow. Even if the 3D views are used in conventional 2D engineering drawings, all of the PMI is localized within the SOLIDWORKS part model.

With 25 years of experience and more than 250 certifications, SolidXperts teams can help you become true 3D experts! An additional question? Need information?

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

By Elene Teolis – PDM Application Specialist at SolidXperts

To establish a connection between the different components of a PDM installation, it must be ensured that communication is possible via the following ports:

PDMWorks Enterprise Archive Server Uses TCP and UDP 3030 Ports

SQL Server uses TCP port 1433 and UDP port 1434

Web server uses HTTP port 80 and HTTPS port 443

SolidNetWork License Server Uses TCP Port 25734

1- Start Windows Firewall

2- Select Inbound Rules and click New Rule

2.1. – Rule type

– Select Port ˃ Next

2.2. – Protocol and ports

– Choose TCP

– Enter the ports to allow ˃ Next

2.3. – Action

– Allow the connection ˃ Next

2.4. – Profile

– Check Domain and Private ˃ Next

2.5. – Name

– Enter a descriptive name for the rule ˃ Next

PDM – TCP IN

PDM – TCP OUT

PDM – UDP IN

PDM – UDP OUT

3- Select Outbound Rules and click on New Rule

3.1. – Rule type

– Select Port ˃ Next

3.2. – Protocol and ports

– Choose TCP

– Enter the ports to allow ˃ Next

3.3. – Action

– Allow the connection ˃ Next

3.4. – Profile

– Check Domain and Private ˃ Next

3.5. – Name

– Enter a descriptive name for the rule ˃ Next

PDM – TCP IN

PDM – TCP OUT

PDM – UDP IN

PDM – UDP OUT

4- Define the Incoming Traffic Rule for the UDP protocol by following the steps in point 2.

– Protocol and ports: choose UDP

5- Define the Outgoing Traffic Rule for the UDP protocol by following the steps in point 3.

– Protocol and ports: choose UDP

You have now successfully opened Windows Firewall ports for SOLIDWORKS PDM! If you want to learn more about new features in SOLIDWORKS from 2015 to 2019, download our White Paper.

SolidXperts teams can help you become true 3D experts! An additional question? Need information?

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Steven Murphy – Certified SOLIDWORKS Expert (CSWE)

So you want to learn SOLIDWORKS? Well, you are in luck- SolidXperts has your back! Whether you are learning SOLIDWORKS as your first Computer-Aided Design (CAD) package or augmenting your software portfolio, this guide will go through the information you need to get you up and running in no time!

Good News: you are not the first person to learn the software! SolidXperts is helping people just like you to learn the software on a daily. The SOLIDWORKS community can also provide a ton of valuable material to augment your learning experience. Here is a list of the resources that you should become familiar with:

The most important resource for getting up to speed quickly on SOLIDWORKS is the online and in-person training courses provided by SolidXperts. These classes are designed to teach new users not only how to use SOLIDWORKS, but to understand the thought process behind design intent. You will work with SOLIDWORKS Experts who will personally cater to your learning style. The “SOLIDWORKS ESSENTIALS” class is the best way to get to where you want to be.

Did you know that SOLIDWORKS has built-in Tutorials to teach you the software? Located under Help (1)> SOLIDWORKS Tutorials (2) > Getting Started (3), there are a series of hands-on tutorials that will walk you through learning the basics of the program.

Well, you already found this blog, so you are on the right track! From walkthroughs to tutorial videos to Q&A threads, the SOLIDWORKS community is here to help you succeed. No matter your skill level, there is tons of value to be gained from interacting with other users who have the same questions as you!

Provided by SOLIDWORKS, MySolidworks contains many training paths (each training path is composed of many individual topic videos) targeting a specific workflow of the software. Use these to your advantage to learn about areas of the software that is relevant to your profession. I would suggest starting with the “Part Modeling Basics” learning path.

*Note: online training works best when it is used to augment in-person training! Good modeling habits developed in the classroom have more staying power and will serve you better in learning the software.

A key portion of getting used to any new software is learning the user interface (UI). You want to be comfortable navigating through the menus. Here is a brief description of the key UI elements for getting started:

The Menu Bar contains a set of the most frequently used tool buttons from the Standard toolbar, the SOLIDWORKS menus, the SOLIDWORKS Search, and a flyout menu of Help options.

The CommandManager is a context-sensitive toolbar that dynamically updates based on the toolbar you want to access. By default, it has toolbars embedded in it based on the document type.

When you click a tab below the CommandManager, it updates to show that toolbar. For example, if you click the Sketches tab, the Sketch toolbar appears.

You can use SOLIDWORKS Search to find information in documentation and forums. You can also find files and models, and find and run a SOLIDWORKS command with just a few keystrokes.

A transparent toolbar in each viewport provides all the common tools required for manipulating the view.

The Task Pane provides access to SOLIDWORKS resources, libraries of reusable design elements, views to drag onto drawing sheets, and other useful items and information. The SolidXperts custom task pane (part of UtilsXperts) has all of our contact information, tools, and custom macros to help our customer base take full advantage of the SOLIDWORKS software.

The FeatureManager design tree on the left side of the SOLIDWORKS window provides an outline view of the active part, assembly, or drawing. This makes it easy to see how the model or assembly was constructed or to examine the various sheets and views in a drawing.

The graphics area displays and lets you manipulate parts, assemblies, and drawings.

Now it is time to start using the program. As suggested earlier, check out the tutorials as they provide a solid explanation of the primary features used in CAD. Since the majority of CAD work only uses a fraction of all of the features available in SOLIDWORKS, focus on understanding these commands to start. Most people find that once you understand the thought process behind the below features, it is really easy to learn the rest! Focus on:

Revolves add or remove material by revolving one or more profiles around a centerline. Use these to create cylindrical or spherical parts in a single feature! A perfect example of a revolve would be a soda can.

Want to remove some material? The Extrude Cut features allow you to get rid of material on your part. Be aware that you need to have material before you can activate the extruded cut command.

Hole Wizard

Hole WizardIf you are looking to make any type of circular hole, look no further! The Hole Wizard contains specifications for the majority of holes, and even lets you bring that information into your 2D drawings automatically. Just select your Hole Type, Size, and Location to make your first hole.

While using these key features is a good starting point, it is not enough. During the SolidXperts courses, we discuss the ins and outs of these features and how to best apply them. Be you want to avoid picking up bad modeling habits!

See that pencil holder on your desk? Model it. What about your phone? Model that too! The more you work to understand completed parts as a combination of extrudes and cuts, the easier it is to CAD. There is no “secret” to getting good at modeling besides practice. At the end of the day, it takes time and a positive attitude to go from a casual user to a master modeler.

So that is it! If you follow this outline, you will have all of the tools you need to start modeling like a champ. Remember that you are only limited by your own creativity, so have fun and continue to grow. If you need help, feel free to give us at SolidXperts a call (we are the Experts!).

SolidXperts teams can help you become true 3D experts! An additional question? Need information?

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

From the 2004 version of SOLIDWORKS onward, the welded construction function speeds up the creation of assemblies because it allows the representation of assemblies without having to create multiple individual files. But, there is more since version 2019.

The new “Structure” function allows the creation of welded constructions in a different way. It is not necessary to draw a path for each profile. For example, it is possible to create a starting profile (“Primary Element”) from:

– From 4 planes;

– Of a path element (a bit like welded construction);

– By defining a length by selecting only one point (note the absence of a sketch in the requested selection);

– By defining an intersection between a face and a plane.

So, with a few clicks, you can define a structure, including corner treatment:

You can then modify the created structure (in one function!) to change the profiles of certain elements:

Following the creation of the external shape of the frame, reinforcements or other elements must generally be attached to it. As mentioned above, creation methods using entities other than sketch segments can be used. For so-called “secondary” elements, using the selection of two existing profiles, two methods are possible:

– Supporting Plan Element” uses an existing plan to position the newly created profile.

Activating chain selection allows the automatic creation of element pairs when two entities are selected.

– Between point elements.

This method has two ways of working, using either distance or length ratio.

The first allows the definition of two distances from the starting point of the profiles:

We can see on the screenshot above that despite the two equally defined distances, the profile is at an angle. The reason for this is that the dimension is defined by the starting point of the profile, which corresponds to the starting point of the sketch, i.e. at the top of the structure for the profile on the left of the screenshot and at the bottom for the profile on the right:

Just click on the appropriate icons to reverse the directions and thus obtain a secondary profile perpendicular to the primary profiles.

Ratios (whose value must vary between 0 and 1) of length relative to each previously selected element can also be used. In this way, always taking the direction into account, it is easy to create a spacer that would be on one side at the upper third of a profile and at the lower third on the other.

As for the creation of a drawing, the operation is the same as for a welded construction.

All in all, even if you are already using welded construction, this new working method can be confusing at first, but you quickly get used to it and learn to appreciate the lightness of the creation tree it produces. Moreover, just like the welded construction, the result produced is compatible with the BeamCutXperts beam optimization tool.

For more information visit our SOLIDWORKS product page, or consult an Xpert!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Repair Resolution –

You might be an engineer – if, you fix broken fitness equipment with CAD and 3D printing. This case study shows just how that was done. It starts with a budget water rower exercise machine that had arm failures in the resistance paddle which spins inside the water tank. The machine had been purchased early in the year and the paddle arms failed by December.

Note that the arms of the original paddle broke off where the plastic transitions from a thinner beam profile to the larger hub. Of course, it could have been predicted by using SOLIDWORKS Flow, Plastics, or Simulation software, but that discussion will be saved for another article.

For the moment we will focus on designing and producing a 3D printed replacement paddle that is more similar to the design used in expensive health club water rower machines.

The commercial grade water rower has single mixing paddle design that extends across the diameter of the tank. There are openings between the shaft hub and the scoop ends, but the paddle has solid plastic arms at the top and bottom of the water tank. The budget rower was connected only at the bottom of the water tank leading to increasing offset dynamic loads as athlete exertion increases.

Although the original design paddle diameter of 18 inches is larger than many 3D printer print volume dimensions, it was possible to get 16 inches diagonally across the build plate. Adjusting the width of the working portion of the paddle and having the solid section on top allows the surface area displacing the water to be similar between the 3D printed design and the injection molded paddle.

By using a pattern of triangle and diamond shapes for the open section, the replacement paddle can be printed without support.Chamfers are used for edge breaks around the edges and openings for better flow characteristics while still being easy to print.

The original paddle had a pressed and brazed connection between the paddle and rower shaft, and this has been replaced with a pentagon shaped hole to allow for screw fastening to the shaft.

For strength Markforged Onyx filament is used which is a carbon and nylon blend. The wall passes are increased and gyroid infill is used along with maintaining the full paddle width through the paddle cross section.

Disassembly of the original paddle from the rower was a bit involved, requiring drilling and a gear puller to get the shaft clear to accept the printed replacement.

Some additional drilling and bolting allowed the new paddle to be installed on the rower shaft.

With a slight adjustment of water volume in the tank, the 3D printed replacement paddle provides the same resistance and workout as the when the machine was new.

Water flow is different with the replacement paddle but the workout is the same. And the repair is done in time for a new year of health resolutions.

John Nolin

Senior Applications Engineer

SolidXperts

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

Installation –

Admin Image types (option) Standard, Remote, Compressed

Remote – allows users to download image from internet / SOLIDWORKS Customer Portal instead of from company VPN

Compressed – smaller download, but must use full package at each service pack upgrade

SOLIDWORKS Electrical – new client or server specific installation options (easier for multi-user environments)

PDM – vault views can now be deployed as part of an Admin Image

Copy Settings wizardcan now adapt to System Options distributed and locked with Admin Image

User Interface –

New message bar pop-up at top of graphics window

Quick Copy utility for Measure tool – allows 1 click copy of values or values + units

Command Search now integrated in Shortcut toolbar (and can be directly added to toolbar)

Drawings saved to PDF can now include the sheet / paper color

Reference Geometry display and selection during Mate, Measure or Pattern.

While in the command hover mouse over faces or cylinders press [Q] to momentarily display reference geometry for selection.

Additional options for Component Tree display to show various combinations of Component Name, Description, Configuration, and Display State.

Sketching –

Linear sketch entity is now usable for direction reference in patterns

Sketch textnow works in patterns

Parts –

Coordinate systems – can be set with exact values in 3D space (independent of a geometry reference to select)

Coordinate systems – can be referenced or selected by its origin, an axis or plane

Cosmetic Threads – better display, retains proper depth and edge attachment

Draft Across Parting Lines – now draft can be applied in both directions from a parting line as 1 feature

External Threaded Stud Wizard – an extension of detailed Thread Feature that builds the stud with threads at 1 time

Hole Wizard Slots – dimension to arc center option added, hit [Tab] to rotate 90deg while placing feature.

Hybrid Modeling – allows mesh bodies (after BREP conversion) to be edited with surface features and combined with solid features

Segmented Mesh bodies – converted mesh bodies can have faces turned into classic BREP

Mirror about 2 planes – with 1 feature creation

Rotate Section View– around a hole or axis

Thickness Analysis – now offers Resolution control with Low, Med, High tessellation sizes

Model Display –

Performance improvement for 3D textures and silhouette edges

Sheet Metal –

Edge flanges on curves can now apply edit profile to limit the feature extents

Etched contours on bends (sketch text or split lines) retain display in flattened state

Structure System & Weldments –

Structure Systems now supports end caps

Custom Properties of older version weldments (2017 or earlier) can be upgraded to newer property architecture

Improvements in Complex Corner property manager

Ability for multiple secondary members (using between points, or up to member methods)

Connector Elements for Structure Systems now supported

Can include cut features as connector is placed.

ImprovedCustom Properties dialog for Structure Systems and Weldments bodies

Assemblies –

(x) Automatically optimize resolved mode, hide lightweight mode

Improves performance by letting system control lightweight use behind the scenes (behaves as resolved to the user)

Open Subassemblies in Different Mode– right click option to load subassembly as LDR or Resolved (independent of upper assembly current mode)

Exclude from BOM – custom configuration property for components

Configuration Table – Design Table functionality without needing the embedded Excel sheet (file size / performance / no excel ???)

Section View – option toexclude failed componentsand still create section view

Assemblies and components with equations will auto resolveas needed, if loaded lightweight

Move with Triad– automatically appears when more than 1 component selected

AdditionalQuick Mates options on In Context Toolbar

Detailing & Drawings –

Alternate Position Viewsnow allow cropping

Predefined Drawing Viewsnow support trimetric, dimetric, or flat pattern types

Detailing Modeimprovements – available for any version file, Save model data and include standard views performance options added

Geometric Tolerance frames now build dynamically on screen

Radius / Diameter dimension display toggle now on incontext bar for easier access

Sheet Metal flat pattern views can now show bend lines when sketch display is hidden

Handling of detailed cut lists within BOMtables is improved

Symmetric Linear Diameter Dimension is added

Import / Export –

Performance improvements forimport of large DXF/DWG and STEP files

Ability to select specific IFC Entity types from the files for import

Assigned colors of entities properly support in DXF/DWG export

PDM –

Improvements with Windows AD integration: additional user data fields, profile import, login validation tools

Improved configuration property managementand control

Archive Server and User log export capabilities added

Preview Tab now shows full eDrawings viewer controls

Performance improvementsfor file operations even when database has higher latency

Manage –

UI improvements for BOM, Project Properties, Process Tab and more

Additional user rights controls over check out of items

Replace User capability added

Performance improvements for BOM and Project display as well as PDM check in/out

Blended Curvature Based Mesher is now default for new studies

Bonded and Contactperformance improvements

Improved solver performance and automatic solver selection

Tools to set camera perspective to matchbackplate

Shadow catcher property can be assigned to scene elements

Scenes Tab UI improvements

Animations improvements for motion studies, key frames and more

Render Output Viewer – in project viewing, control, and management of renders

Pattern Tool – replaces and improves prior Formation function (Vee, Circle, Scatter, Grid)

CAM –

Toolpath endpointscan be set for a custom color for easier viewing

Filter for Mill & Turn tools containing specified text string

Composer –

Ability to import SOLIDWORKS appearance decals

Import file versionextensions: ACIS up to 2021 , Creo 7, SOLIDWORKS 2022

Electrical –

Links in BOM cells – allows multiple items to reference 1 mfg part

PDF data file support for Project PDF exports (bind PDF function)

Multiple UI improvements

Attribute capability added to Origin & Destination arrows (shows mark of connected component)

Electrical Content Portalcan now be set as dockable panel in UI

Improved Connection Point creation

Inspection –

New API– auto open SOLIDWORKS files, Balloon drawings, create reports and more

Standalone now supportsall native SOLIDWORKS files and NX/Unigraphics *.prt files (MBE)

Smart Extract in standalone has improved recognition and parsing of PDF file content

MBD –

HTML(5) exportoption on 3D PDF creation

Angle Dimension manual annotation for DimXpert added

Geometric Tolerancingimprovement including ANSI Y14.5 or ISO 1101 release selection

Support for SOLIDWORKS custom file properties when saved as eDrawings files

Components list UIimprovements

Scene Plot utility – stores all displayed plots and model display

Compare Tool improvements

Range Function – for handling of transient effects (such as power derating due to temperature calculation)

Flux Plot – now available within Transient Explorer

Plastics –

Symmetric & Cyclic Cavity and Runner Layout tools

Injection Location Advisor – based on part geometry software selects up to 4 recommended injection locations

Polymer materials data updates (using latest manufacturer properties)

SABIC, Polyplastics, Solvay Specialty Polymers, Radici Group, LANXESS

Improved UI of Plastics Manager Tree

4K and higher displayresolution support

Solver performance improvement – cooling calculation time reduced 34%, Fill & Pack reduced 60%

Routing –

Flatten Routeimprovements for horizontal selection, and line only output

Connector backshellsupport added

Replace Connectorcapability added – preserves line connection where possible

SolidXperts teams can help you become true 3D experts! An additional question? Need information?

Contact us!

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free:

By Marco Chery – SolidXperts Application Specialist

What is an adaptive form?

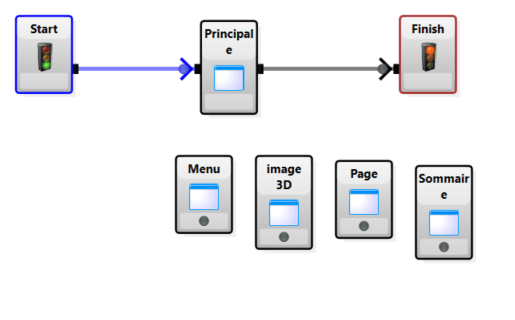

DriveWorks projects created using responsive forms adjust their content regardless of the size and orientation of your device screen, whether it is a computer, tablet, or smartphone. This eliminates the need to swipe the web page from left to right to see content and the user’s browsing experience is more intuitive.

Why should you use them?

A Few Tips

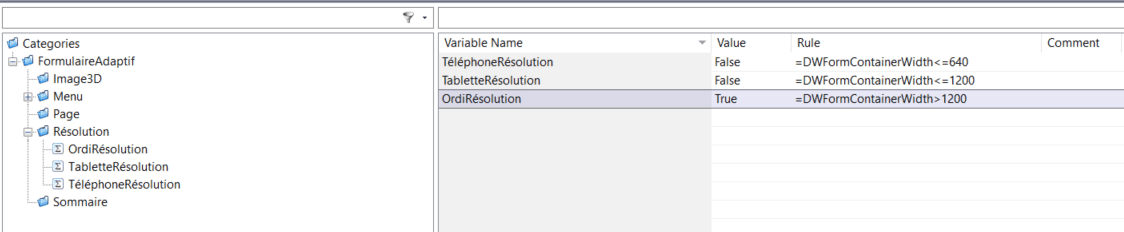

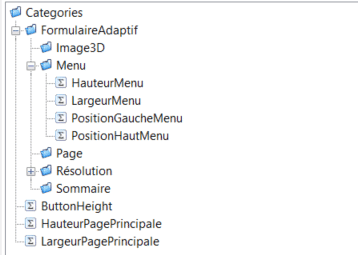

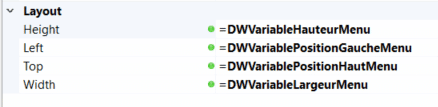

The easiest way to make your forms responsive is to use Frame Controls on the main page. From this main page, the windows will allow you to see the content of your different forms.

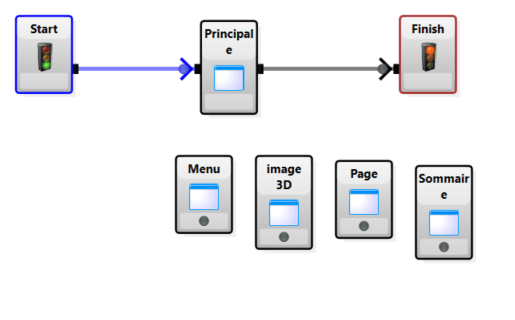

Second, create a plan to switch these windows to the screen of a phone and tablet.

Third, determine the borders for switching windows between different device resolutions. For this, we use a special DriveWorks variable: FormContainerWidth.

This method ensures your DriveWorks project forms are adaptive and attractive, regardless of the device on which they are viewed.

SolidXperts teams can help you become true 3D experts! An additional question? Need information?

SolidXperts team is always there for you!

Any questions? Need help? Ask one of our experts.

Whether you’re ready to get started or just have a few more questions, you can contact us toll-free: